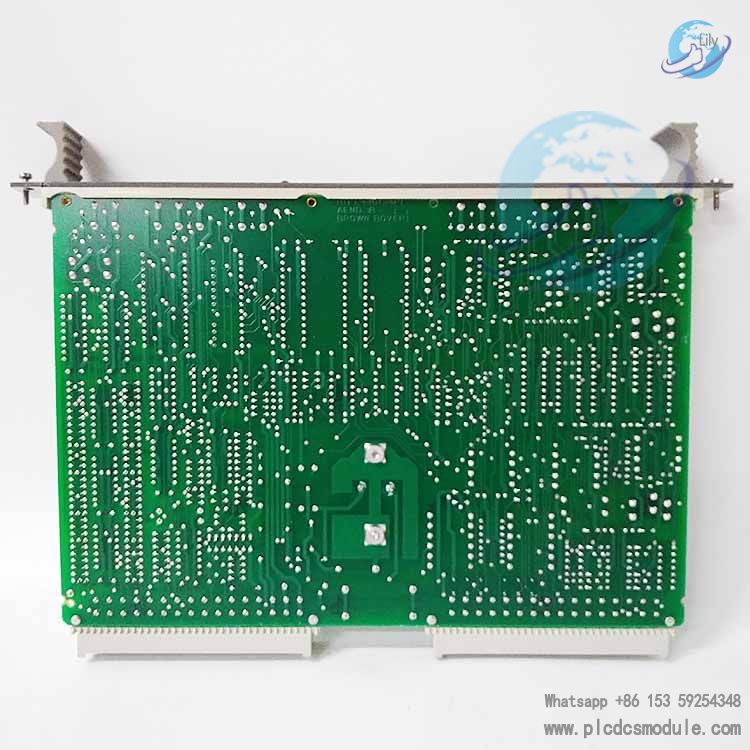

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. FM9925A-E HIEE451116R0001 is a high-performance control board belonging to the ABB Procontrol P14 automation system series, essentially a printed circuit board (PCB) dedicated to industrial automation control. Its core positioning is process control and data acquisition, tailored to the requirements of precise control and system integration in harsh industrial scenarios. Adopting a dual-core processor architecture, it supports flexible expansion of analog and digital I/O modules, and enables convenient system integration, expansion and maintenance with its modular design. Meanwhile, it is compatible with a variety of mainstream industrial communication protocols, allowing seamless interconnection with ABB devices of the same series and third-party systems. It also features a comprehensive electrical protection mechanism to ensure long-term stable operation. This control board is widely applied in the automation control systems of industries such as power, petrochemical, metallurgy, chemical engineering and machinery manufacturing, undertaking core control tasks including signal processing, logical operation and command output.

Core Functions

High-precision Process Control: Leveraging the powerful computing capability of the dual-core processor, it can accurately process analog (0-10V or 100V DC - 240V DC input) and digital signals, adapt to various sensors and actuators, and realize closed-loop precise regulation of industrial processes, meeting the demand for stable parameter control under complex working conditions.

Flexible I/O Expansion: It supports the access of multiple types of analog and digital I/O modules with a maximum output current of 1A. The number of I/O points can be flexibly increased or decreased according to the actual control scale, adapting to control scenarios of different complexities and reducing system redundancy costs.

Multi-protocol Communication and Interconnection: Integrated with RS485 and Ethernet interfaces, it natively supports mainstream industrial communication protocols such as Modbus and Profibus DP, enabling high-speed data interaction with upper computers, PLCs, frequency converters and other devices. It also supports remote monitoring and diagnosis to improve the efficiency of system operation and maintenance.

Highly Reliable and Safe Operation: Built-in overvoltage, overcurrent and overtemperature protection circuits can effectively respond to sudden conditions such as power grid fluctuations and load abnormalities in industrial sites to avoid equipment damage; it has excellent electromagnetic compatibility, which can resist electromagnetic interference and electrostatic interference, ensuring the stability of signal transmission and control logic.

Convenient System Maintenance: Adopting a draw-out structural design with modular components, it facilitates rapid on-site disassembly, assembly and replacement, greatly shortening maintenance downtime; it is compatible with the standardized debugging tools of the ABB Procontrol P14 system, simplifying the processes of parameter configuration and fault troubleshooting.

Technical Parameters

Power Supply Specifications: The operating voltage is 24V DC, compatible with DC power supply systems commonly used in industrial sites; the input voltage range covers 0-10V (for control signals) or 100V DC - 240V DC (for wide voltage adaptation scenarios).

Environmental Adaptability: The operating temperature range is -20°C to +70°C, capable of withstanding high and low temperature industrial environments; it has a protection class of IP20 with basic dustproof performance, suitable for the installation environment of conventional control cabinets.

Physical Specifications: With dimensions of 250mm×150mm×20mm and a weight of approximately 500g, it features a compact design that saves installation space and is compatible with the layout of standard control cabinets.

Performance Indicators: The dual-core processor ensures high-speed computing and supports millisecond-level signal response and control command output; the data transmission rate of the communication interface complies with the corresponding protocol standards, meeting the low-latency requirements of industrial real-time control.

Structural Features: Adopting high-quality electronic components and precision production processes, the board has a robust structure; its draw-out design facilitates installation and maintenance, making it suitable for industrial working conditions requiring long-term continuous operation.

Application Scenarios

Power Industry: Used in the monitoring systems of substations and power generation equipment to realize real-time acquisition and regulation of parameters such as voltage, current and temperature, ensuring the stable operation of power equipment.

Process Industry: Undertakes the control of process parameters for equipment including reaction kettles, pipeline valves and pump units in the production lines of petrochemical, metallurgical, chemical and other industries, such as the closed-loop regulation of pressure, flow and liquid level, improving production efficiency and the stability of product quality.

Mechanical Manufacturing: Adapted for the logic control and motion coordination of automated production lines, such as the sequential control of linked equipment and the precise adjustment of processing parameters, helping to achieve flexible production.

Data Acquisition System: Serves as a core acquisition unit to integrate data from various industrial on-site sensors and upload it to the data platform via communication protocols, providing data support for production scheduling and fault early warning.

3005319639

3005319639