It enables real-time data transmission and command interaction between the controller, distributed I/O modules, drive devices, and third-party intelligent devices. Widely used in industrial scenarios with strict requirements for communication reliability and real-time performance—such as petrochemicals, electric power, metallurgy, and papermaking—it is a key component for building large-scale distributed control networks.To achieve complete AF100 bus communication functions, this module needs to be used in conjunction with ABB Advant Controller 450 series controllers, SC510/SC520 sub-module carriers, S800 I/O systems, AF100 dedicated communication components (e.g., TC512V1, TC625, TK803), and related auxiliary equipment.

Document Download:

Core Functions and Technical Features

In-depth AF100 Bus Adaptation: Natively supports the Advant Fieldbus 100 protocol. A single module can access 1 AF100 bus (compatible with multiple transmission media such as coaxial cables, twisted pairs, and optical fibers), with a maximum communication distance of up to 13,300 meters (for coaxial media). It can meet the cross-regional and long-distance device interconnection needs of large factories, while supporting two redundancy modes—bus redundancy and media redundancy—to significantly improve the fault resistance of communication links.

High-speed Real-time Data Transmission: Adopts an optimized communication mechanism to maintain stable data transmission rates, enabling efficient transmission of multiple data types including analog quantities, digital quantities, and control commands. Combined with the high processing performance of the Advant Controller 450, it achieves millisecond-level data response, ensuring the real-time performance of parameter collection and command issuance in process control, and adapting to the dynamic regulation needs of continuous production processes.

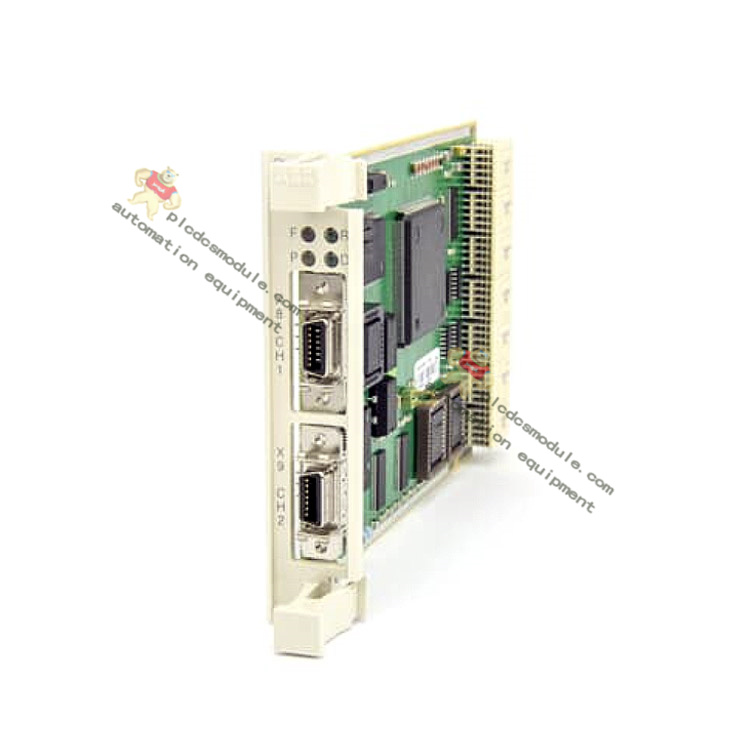

Flexible Hardware Compatibility: The module is designed to be compatible with the RF533 controller subrack of the Advant Controller 450, and can be installed in the slots of SC510 (without built-in processor) or SC520 (with built-in processor) sub-module carriers. A single carrier can be configured with multiple CI522A modules (subject to the total slot limit of the subrack). It supports parallel deployment with other communication modules (such as PROFIBUS-DP module CI541V1 and LONWORKS module CI572) to build a multi-bus collaborative communication architecture.

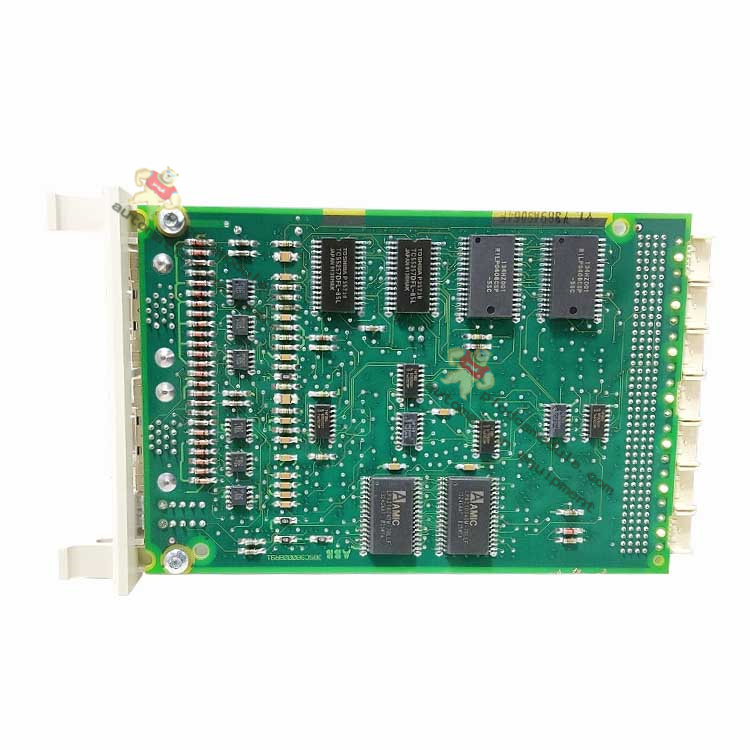

Industrial-grade Reliability Design: Adopts hardware circuits and protection technologies resistant to electromagnetic interference (EMC), complying with the requirements of EMC Directive 89/336/EEC and Low Voltage Directive 72/23/EEC, and is marked with CE certification. Its operating temperature range covers the harsh environments commonly found in industrial sites. Meanwhile, the module is equipped with fault diagnosis indicator lights (e.g., power, communication, and redundancy status lights) that can provide real-time feedback on operating status, facilitating quick identification of issues such as bus interruptions and module failures, and reducing maintenance costs.

Convenient Configuration and Management: Parameter configuration must be performed via the Advant Station 140 engineering station (equipped with AMPL Control Configuration version 1.7 or above). It supports setting key parameters such as bus topology, transmission cycle, and redundancy strategy through a visual interface. Additionally, it enables real-time monitoring of indicators like bus load and data transmission error rate, allowing operation and maintenance personnel to efficiently manage and optimize the AF100 network.

Compatible Systems and Installation Specifications

Core Controller and Carrier Compatibility: Specifically designed for the Advant Controller 450 series controllers, it must be used with PM511V08 (8Mbyte RAM) or PM511V16 (16Mbyte RAM) processor modules. Data interaction is realized through the FB+ (IEEE 896) system bus of the controller subrack. During installation, it must rely on the SC510 or SC520 sub-module carrier. The carrier needs to be inserted into the Part A area (FB + module slot) of the RF533 subrack, and it is necessary to ensure the normal connection of the power supply and signal links between the carrier and the controller subrack.

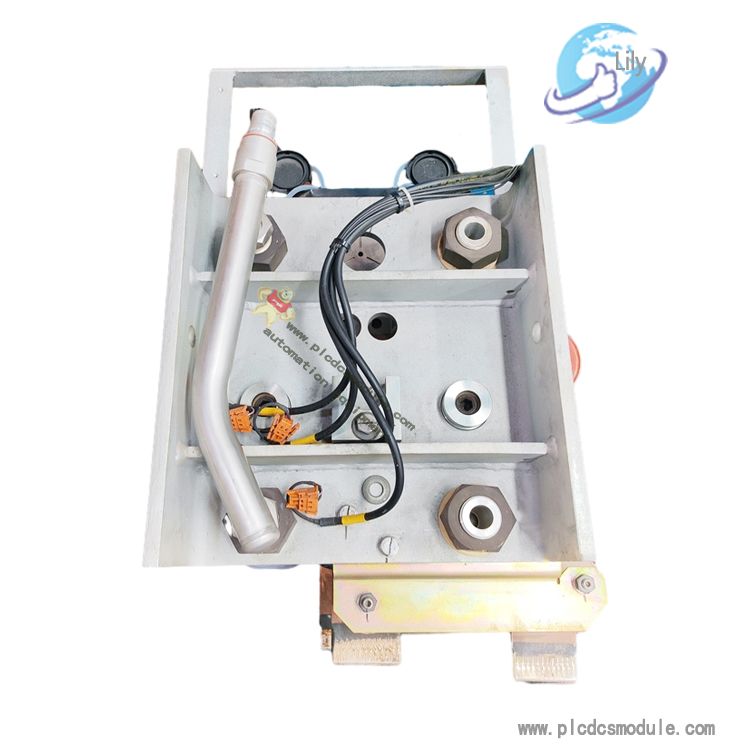

AF100 Bus Component Matching: Corresponding AF100 dedicated components must be matched according to the type of transmission medium. If twisted-pair medium is used, it is necessary to match TC512V1 (twisted-pair medium module) and TK803 (connection kit); if coaxial medium is used, it must be matched with TC625 (coaxial medium module) and TK803; if medium redundancy is required, two sets of medium modules (such as 2 TC512V1) and two sets of TK803 must be configured; if bus redundancy is required, 2 CI522A modules and corresponding two sets of medium components must be configured to ensure the physical independence of the redundant link.

Power Supply and Physical Installation Requirements: The module power supply is provided by the SR511 voltage regulator (output 24V/5V) of the controller subrack, and it is necessary to ensure that the power supply voltage is stable and meets the rated requirements of the module. Physical installation must comply with ABB system installation specifications. The wiring between the module, medium module and connection cable must be firm. The coaxial cable must use a dedicated BNC connector, and the twisted-pair cable must pay attention to impedance matching (150Ω). At the same time, the control cabinet where the module is located must have good grounding measures to enhance the anti-electromagnetic interference capability.

Application Scenarios

Large-Scale Petrochemical Process Control: In scenarios such as petroleum refining and chemical synthesis, the CI522A module connects distributed S800 I/O modules (e.g., AI801 analog input module, AO801 analog output module) via the AF100 bus to collect parameters like reactor temperature, pressure, and liquid level. Meanwhile, it connects to drive devices such as DCS 500B, DCS 600, and ACS 600, and sends control commands from the Advant Controller 450 to actuators to realize automatic regulation of the production process. The bus redundancy design prevents production interruptions caused by a single communication failure.

Power System Equipment Interconnection: In power plants and substations, the module connects power meters, relay protection devices, and S800 I/O modules through the AF100 bus to achieve centralized collection of parameters such as power generation, voltage, and current. It also supports communication with remote control centers, and together with the monitoring function of the Advant OCS system, enables remote monitoring and dispatching of power equipment. Its long-distance communication capability meets the needs of multi-plant and wide-range equipment layout in power plants.

Papermaking/Metallurgy Production Line Integration: In continuous production lines for papermaking and iron & steel, the module connects devices in various links of the production line, such as sensors (e.g., tension sensors, temperature sensors), frequency converters, and motor controllers. It realizes collaborative communication between devices via the AF100 bus and transmits production parameters to the Advant Controller 450 in real time, ensuring stable control of key parameters like production line speed, tension, and temperature, and improving product quality consistency.

3005319639

3005319639