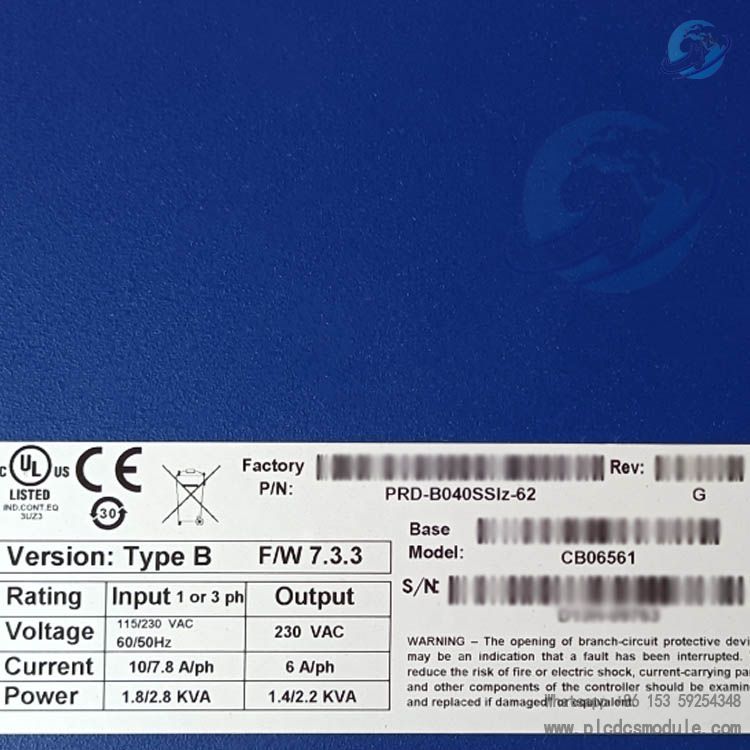

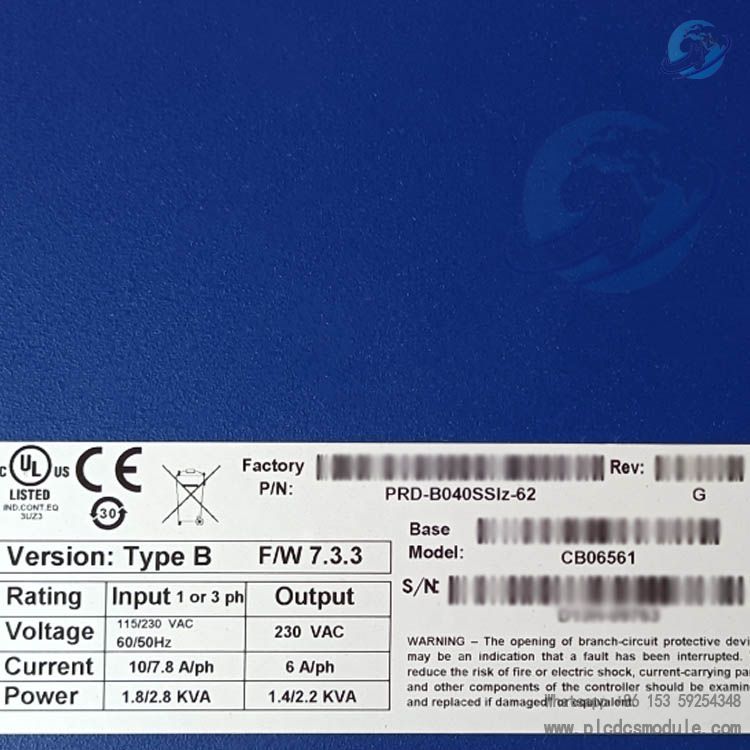

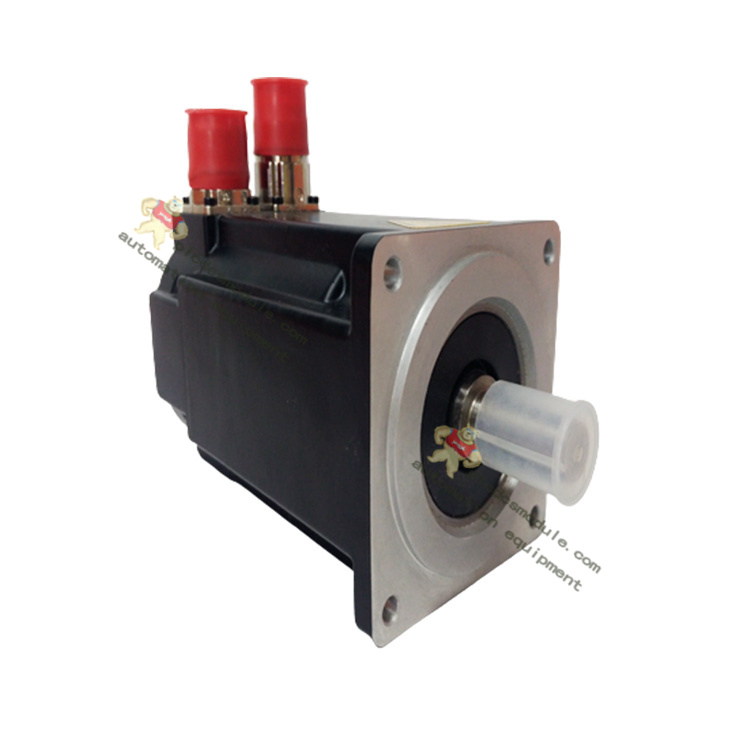

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The Kollmorgen CB06561 PRD-B040SSLZ-62 servo drive is a key component of advanced motion control solutions, demonstrating exceptional performance. It supports 115/230V AC input voltage in either single-phase or three-phase configurations, enabling adaptation to diverse power supply environments. With a rated output current of 6A per phase, it delivers stable power output, providing 1.4kVA in single-phase mode and 2.2kVA in three-phase mode under 230V AC. Leveraging advanced algorithms and digital control technology, it achieves precise torque regulation, ensuring high precision and stability in equipment operation. The CB06561 PRD-B040SSLZ-62 servo drive features abundant connection options, facilitating seamless integration with various automation systems and helping enhance the efficiency and precision of industrial automated production.

Technical Specifications of CB06561 PRD-B040SSLZ-62 Servo Drive

- Rated Voltage: 24V DC

- Input Voltage Range: 18–36V DC

- Output Voltage: 24V DC

- Power Range: 0.6–9 kW

- Current Range: 1–100 A

- Control Modes: Position control, speed control, torque control

- Communication Interfaces: CANopen, EtherCAT

- Protection Class: IP20 or higher

- Operating Temperature Range: -20°C to +60°C

- Response Speed: Output frequency up to 30 kHz

Performance Features

- High-Precision Control: Utilizes advanced control algorithms to achieve micron-level motion accuracy, ensuring stable and precise motor operation.

- Efficient Energy Conversion: Integrates high-efficiency power conversion technology to minimize energy loss and enhance system efficiency.

- Comprehensive Protection: Features overload, overcurrent, and overheat protection to safeguard against unexpected damage and improve system reliability.

- Easy Integration: Compatible with multiple control systems (e.g., Modbus, EtherCAT) for seamless integration into existing automation frameworks.

- Optimal Thermal Management: Designed with efficient heat dissipation to maintain performance under high loads and extend service life.

- Advanced Functionality: Equipped with IntelaTrac 4.0 capabilities, including configuration management and scalable architecture for simplified operation and maintenance.

Application Areas

Industrial Automation: CNC machines, machining centers, packaging machinery, textile equipment.

Robotics: Industrial and collaborative robots requiring precise joint control.

Semiconductor Manufacturing: Wafer cutting machines, robotic wafer handling systems.

Medical Devices: High-precision motion control for diagnostic and therapeutic equipment.

- Ensure the installation environment is dry and well-ventilated (temperature: -20°C to +60°C; humidity: ≤90% RH, no condensation).

- Keep away from strong electromagnetic interference sources (e.g., large motors, transformers).

- The mounting surface must be flat and meet IP20 or higher protection class requirements.

- Verify that the drive model (CB06561 PRD-B040SSLZ-62) is compatible with the motor specifications.

- Check for external damage and loose terminals.

Power Supply Connection:

- Input voltage: 24V DC (range: 18–36V DC).

- Ensure sufficient power supply capacity; an isolation transformer is recommended.

Motor Connection:

- Connect the U, V, W three-phase windings according to the markings.

- Connect encoder feedback cables (supports Resolver, SFD, etc.).

Control Signals:

- Connect digital/analog input/output signals (e.g., start/stop, speed commands).

- Use shielded twisted-pair cables for communication interfaces (CANopen/EtherCAT).

Grounding:

- Ensure reliable grounding of the drive housing and cabinet (ground resistance < 1Ω).

- Set motor type (permanent magnet synchronous/asynchronous), rated current, and power.

- Configure encoder type and resolution.

- Select control mode (position/speed/torque control).

- Adjust PID controller parameters (proportional, integral, derivative).

- Set acceleration/deceleration time (100–500ms recommended).

- Configure electronic gear ratio (calculated based on mechanical transmission ratio).

- Check wiring correctness without power supply.

- Use a multimeter to measure terminal resistance and confirm no short circuits.

- First, switch on the control power and observe the indicator light status.

- Gradually increase the main power voltage and monitor input current.

- Send low-speed operation commands (e.g., 100rpm) via software.

- Check if the motor rotation direction is correct.

- Monitor current and temperature to ensure they are within rated ranges.

- Gradually increase the load and test dynamic response performance.

- Optimize PID parameters to eliminate oscillation or overshoot.

- Test stability during acceleration and deceleration.

- E001: Overvoltage fault → Check power supply voltage fluctuations.

- E002: Overcurrent fault → Inspect motor windings for short circuits.

- E003: Overload fault → Reduce load or increase drive capacity.

- E010: Encoder fault → Check feedback cable connections.

- Refer to the drive manual for the corresponding fault code table.

- Use diagnostic tools to read real-time data (e.g., current, temperature).

- Contact Kollmorgen technical support (fault logs required).

- Disconnect the main power supply before debugging and wait for capacitor discharge (approximately 5 minutes).

- Avoid contact with exposed terminals to prevent electric shock.

- Keep the protective cover closed during debugging.

- Professional personnel must be present during the first power-on.

Customers who purchased this product are also browsing the following products:

GE DS200FGPAG1AHD Mark VI Gate Pulse Amplifier Board

GE ESP10B Pressure and flow controllers

HONEYWELL TC-IAH161 Analog Input Module

HIMA F8628X 984862865 Communication Modules

3005319639

3005319639