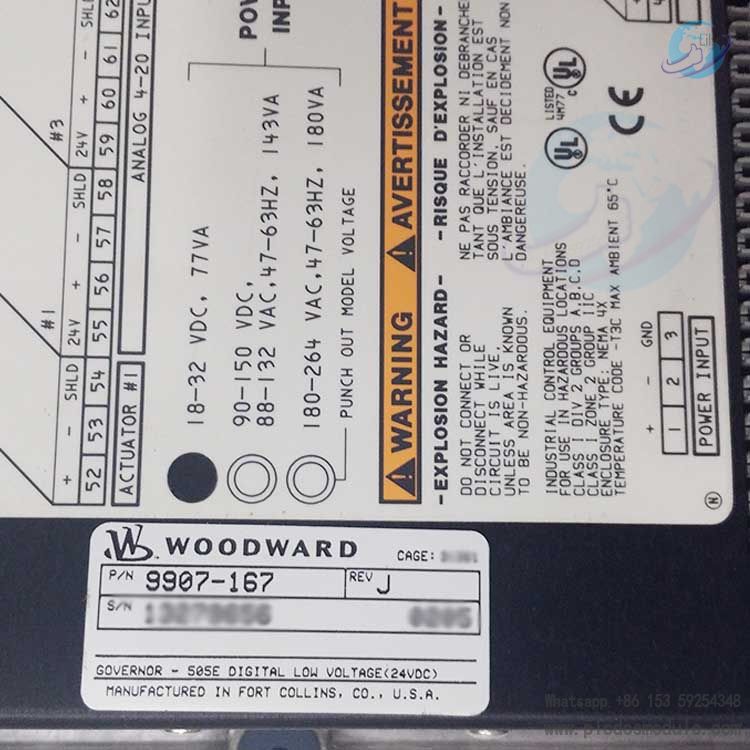

Woodward 9907-167 is a digital speed governor for steam turbines, belonging to the 505E series. It is specifically designed for steam turbines with extraction or admission control. Adopting a 32-bit microprocessor architecture, it supports on-site programming and can be configured as an independent unit or integrated with a Distributed Control System (DCS) through menu-driven software. The device features high-precision speed control, extraction/admission pressure regulation and other functions. It is suitable for monitoring key equipment in industries such as power, petroleum, and chemical engineering, which can effectively ensure the operational stability of steam turbines and prevent mechanical failures.(9907-164、9907-165)

data table

Technical Specifications

Power Supply: 18-32Vdc (LVDC), maximum current 12mA, with short-circuit and overload protection.

I/O Configuration:

8 differential analog inputs (16-bit resolution, 250kS/s sampling rate);

2 analog outputs;

32 digital I/O channels;

4 x 32-bit counters.

Communication: Dual Modbus ports (RS-232/422/485, supporting ASCII/RTU protocols) for remote parameter configuration and monitoring.

Operating Environment:

Temperature: -25°C to +65°C (standard);

Protection level: IP56 (requires matching enclosure);

Vibration resistance: 1.5g (5-500Hz).

Key Features

Reconfigurable FPGA Architecture: Enables custom signal processing algorithms and real-time response to external events (sub-microsecond delay).

Multi-Parameter Control: Simultaneously regulates speed, extraction/admission pressure, supporting cascade control, load distribution, and other functions.

Safety Protection Mechanisms: Independent overspeed shutdown device, watchdog timer, and electrostatic discharge protection (ESD).

Flexible Startup Modes: Supports automatic, semi-automatic, and manual startup, with critical speed avoidance and automatic warm-up logic.

Advantages

High-Precision Measurement: Linearity ±1%, sensitivity -7.87V/mm, compatible with reluctance or proximity sensors.

Anti-Interference Capability: Enhanced RFI/EMI protection, compliant with European EMC standards, suitable for high-frequency industrial environments.

Convenient Maintenance: SpringLoc terminals for tool-free wiring, support for online dynamic parameter adjustment, and visual fault diagnosis.

Technical Parameters

Application Fields

Installation and Maintenance

Installation Methods

Mounting via DIN rail or panel mounting. Ensure good ventilation and avoid strong electromagnetic sources.

Wiring Requirements

Use shielded twisted-pair cables. Separate sensor cables from power cables. Grounding resistance should be < 1Ω.

Maintenance Key Points

Regularly inspect terminal connections.

Calibrate sensor linearity annually.

Update firmware via Service Mode.

Supporting Products

Sensors

3300 XL 8mm proximity probes, magnetoresistive sensors (MPU).

Communication Equipment

Modbus gateway, RS-485 repeater (for long-distance communication).

Auxiliary Controls

Woodward DSLC digital synchronizer (for load sharing), Turbine Emergency Trip System (ETS).

Customers who purchased this product are also browsing the following products:

Woodward 9907-164 Steam Turbine Control Speed Controllers

Woodward 8402-271 P/N 5852-1036 Electromagnetic intake valve

Schneider 140CPU67160 CPU Module

SST PROFIBUS SST-PB3-PCU-2 |Woodhead | PC Network Interface Card

ICS TRIPLEX T8480 Trusted TMR Analogue Output Module

3005319639

3005319639