Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication.

The GE HYDRAN M2 Mark III Enhanced Dissolved Gas Analysis (DGA) Monitoring System for Transformer Oil is a compact online device based on GE proven field technology, dedicated to oil-immersed transformer health management. As a 3rd-generation upgrade, it focuses on real-time monitoring of dissolved fault gases and moisture, integrates IEEE/IEC-compliant transformer models, and breaks traditional single-parameter limitations to detect potential risks like insulation aging and reduced cooling efficiency. The economical, all-in-one Hydran M2 (permanently mounted) alerts personnel to developing faults, monitoring either composite fault gas levels (ppm), hydrogen only (per sensor), or oil moisture (%RH/ppm). With a large global installed base, compatible with mineral and low-flammability ester oils, it meets power facilities needs for critical medium transformers, reduces industrial process interruptions from outages, and supports asset life extension and O&M cost optimization.

related documents

Hydran_M2.pdf

Hydran_M2.pdf

Hydran M2.pdf

Hydran M2.pdf

I. Multi-Dimensional Parameter Monitoring Capability

Fault Gas Monitoring: Two sensor options are available. The first is a "composite gas sensor," which can accurately detect the concentrations (unit: ppm) of hydrogen (H₂, a general fault gas), carbon monoxide (CO, an indicator of paper degradation), acetylene (C₂H₂, an indicator of arc discharge), and ethylene (C₂H₄, an indicator of oil overheating). The second is a "pure hydrogen sensor," which focuses on monitoring hydrogen—a key gas for early fault detection—to meet monitoring accuracy requirements in different scenarios.

Moisture-in-Oil Monitoring: Equipped with a built-in moisture sensor, it displays the moisture content in oil in two units: relative humidity (% RH) and ppm. It can promptly identify insulation paper degradation (accompanied by CO and moisture generation) or gasket leakage issues, preventing insulation performance degradation caused by moisture.

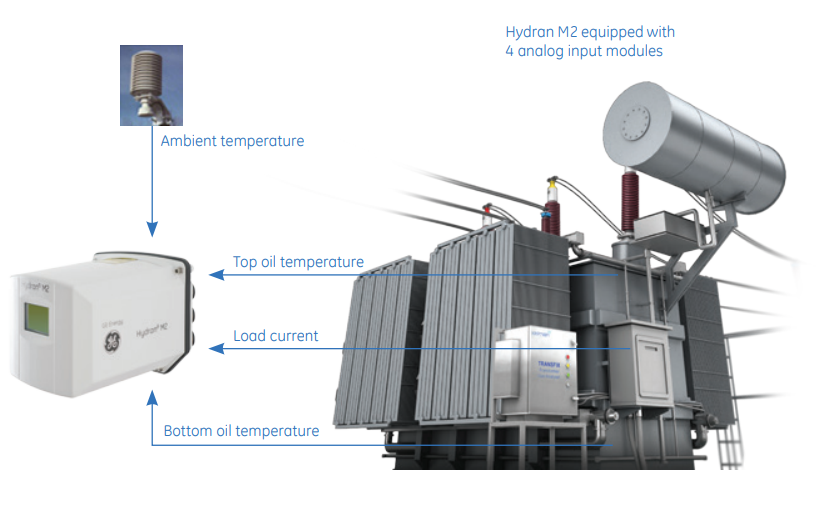

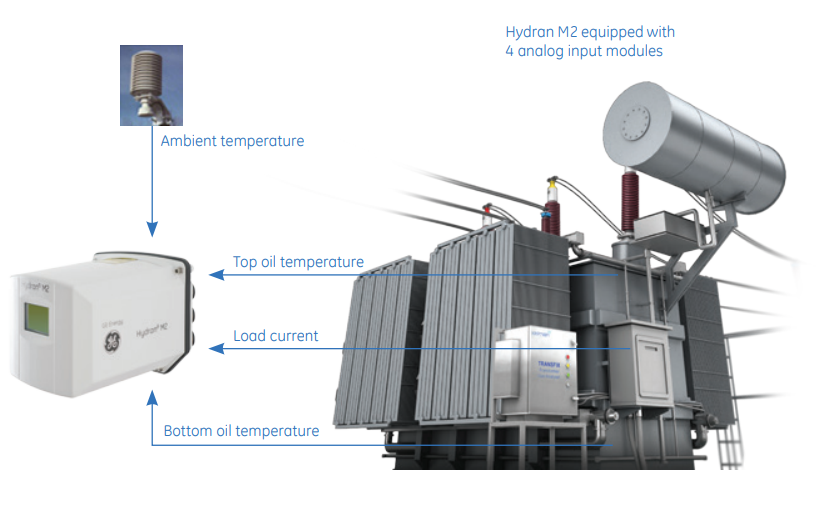

Extended Parameter Collection: By connecting additional sensors, it can monitor key variables such as top/bottom tank oil temperature, transformer load current, ambient temperature, and cooling group status. These data are analyzed in conjunction with Dissolved Gas Analysis (DGA) and moisture data to achieve comprehensive control of transformer operating conditions.

II. Transformer Mathematical Models Based on Standards

On-board mathematical models built in accordance with IEEE and IEC standards convert raw data collected by sensors into intuitive health status information. The core calculation content and value of each model are as follows: The Winding Hot-Spot Temperature Model calculates the hot-spot temperature of windings under monitored load current to avoid accelerated insulation aging caused by winding overheating. The Insulation Aging Model calculates insulation life loss in accordance with IEEE /IEC guidelines, enabling quantification of remaining insulation life and guiding maintenance timing. The Paper Moisture and Gassing Model calculates the moisture content in winding insulation paper and the critical temperature for gas gassing, preventing insulation breakdown and bubble discharge risks caused by moisture. The Main Insulation Pressboard Moisture Model monitors the moisture content in the main insulation pressboard barrier to ensure long-term stability of the main insulation system. The Cooling Efficiency and Cooling Group Model real-time monitors the actual efficiency of the cooling system and calculates the cumulative operating time of each cooling group, facilitating timely detection of cooling faults and avoiding equipment overheating due to insufficient heat dissipation. The Tap Changer-Related Model tracks the position of the on-load tap changer (OLTC), records operation history, and calculates the temperature difference between the OLTC tank and the main tank to assess the operating status of the tap changer and prevent switching faults. The MVA Model calculates the apparent power of windings under monitored load current, helping grasp the actual load capacity of the transformer and avoid overload operation.

III. Ease of Installation and Operation & Maintenance

Convenient Installation: Adopting a single-valve installation design, it requires no additional pipelines or pumps and can be directly mounted on the existing transformer oil valve. Deployment is usually achievable without power outage, significantly minimizing impacts on power grids or industrial production.

Low-Maintenance Feature: The device has no moving parts, reducing the risk of mechanical failures. It is equipped with a built-in automatic self-test function every 15 days. In case of power failures, oil valve closure, sensor malfunctions or other issues detected, a service alarm will be triggered, lowering manual inspection costs.

On-Site Upgrade Capability: Supporting analog signal access and I/O expansion, it allows adding sensors or functional modules based on later needs, flexibly adapting to the dynamic requirements of transformer operation and maintenance.

System Configuration and Communication Capabilities

1. Hardware and Protection Configuration

The enclosure is designed to meet the NEMA 4X (IP66) protection rating, boasting excellent resistance to dust, water and corrosive gases. It is adaptable to harsh outdoor environments and complex working conditions in industrial sites, ensuring the long-term stable operation of the equipment. A local alphanumeric display and a scrolling control keypad are equipped to support on-site viewing of monitoring data and setting of parameter thresholds. The integrated data visualization function streamlines the operation process, enabling operation and maintenance personnel to quickly obtain key information.

In terms of alarm and diagnostic output, the system is configured with 4 programmable relay contacts, which support setting hierarchical alarms (early warning and emergency alarm) for gas concentration, moisture content, analog input parameters and other metrics, and can trigger alarms based on the specific values or change trends of parameters to timely indicate the severity of faults. It is also equipped with 1 dedicated self-test diagnostic relay contact to quickly feed back the real-time operating status of the equipment itself. The data storage and logging function supports recording events and monitoring data at an adjustable rate, facilitating the traceability of the equipment's historical working conditions and providing sufficient data support for fault root cause analysis and trend analysis.

2. Flexible Communication and Integration Options

The system features a rich array of communication interfaces, including a locally isolated RS-232 serial port, an isolated RS-485 serial port for remote communication, and 1 communication expansion card slot. It can be connected to a 10/100BaseT Ethernet card or an analog modem according to actual needs, flexibly meeting the diversified requirements of local debugging and remote data transmission.

In terms of protocol compatibility, the system supports the DNP3 protocol (serial or TCP/IP mode) and the IEC 61850 protocol, enabling seamless integration into various SCADA (Supervisory Control and Data Acquisition) or DCS (Distributed Control System) platforms. It realizes smooth data interconnection with existing operation and maintenance management systems without the need for system reconstruction.

For software adaptability, the system is fully compatible with GE Perception software, through which functions such as transformer health data download, trend analysis and fault diagnosis can be realized, providing the operation and maintenance team with a unified and efficient data analysis and management platform.

Core Application Value

Through the synergy of real-time monitoring and dynamic modeling, this system can effectively reduce the risk of unplanned failures (including catastrophic ones) in transformers, avoiding the costly cleanup expenses, equipment replacement costs and unplanned downtime losses caused by such failures.

In terms of operation and maintenance cost optimization, continuous condition monitoring and early fault warning can significantly extend the regular maintenance cycle and reduce the human and material input for patrol inspection and maintenance. By optimizing the operational performance of transformers and prolonging their service life, the system can notably defer capital investment in major equipment replacement, thus helping enterprises save operational costs.

Meanwhile, equipment condition assessment based on real-time data enables operation and maintenance personnel to gain a more accurate grasp of the expected service life of transformers, formulate more scientific and rational asset management systems, enhance the stability and reliability of power supply and industrial production, and create greater economic and operational value for enterprises.

Customers who purchased this product are also browsing the following products:

GE IS200TRLYH1BHH Mark Vie Relay Output Terminal Board

GE Multilin MMII-PD-1-2-120 Mm2 Motor Manager

GE Hydran 201Ti Mark IV Essential DGA monitoring for transformers

GE H201CI-1 Mark IV Essential DGA monitoring for transformers

3005319639

3005319639