Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication.

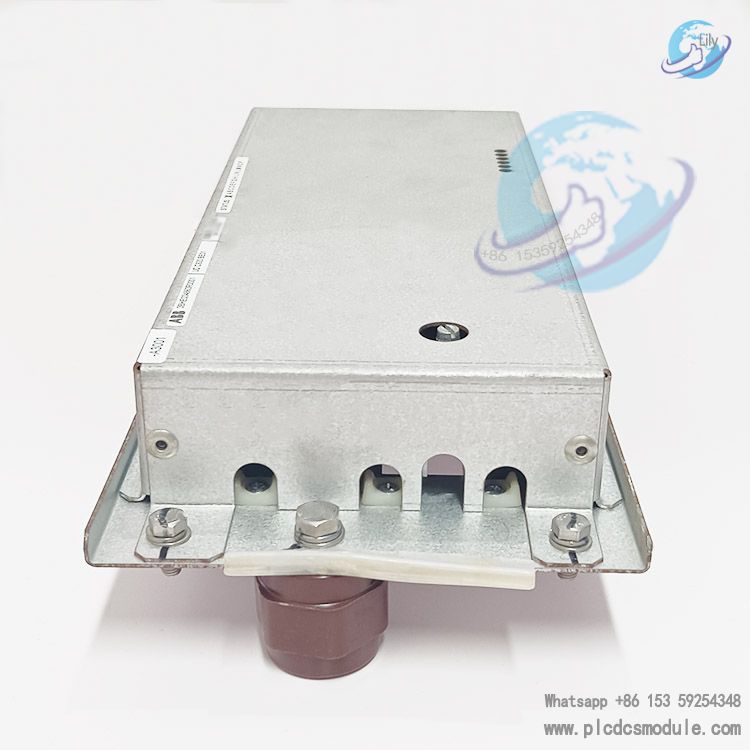

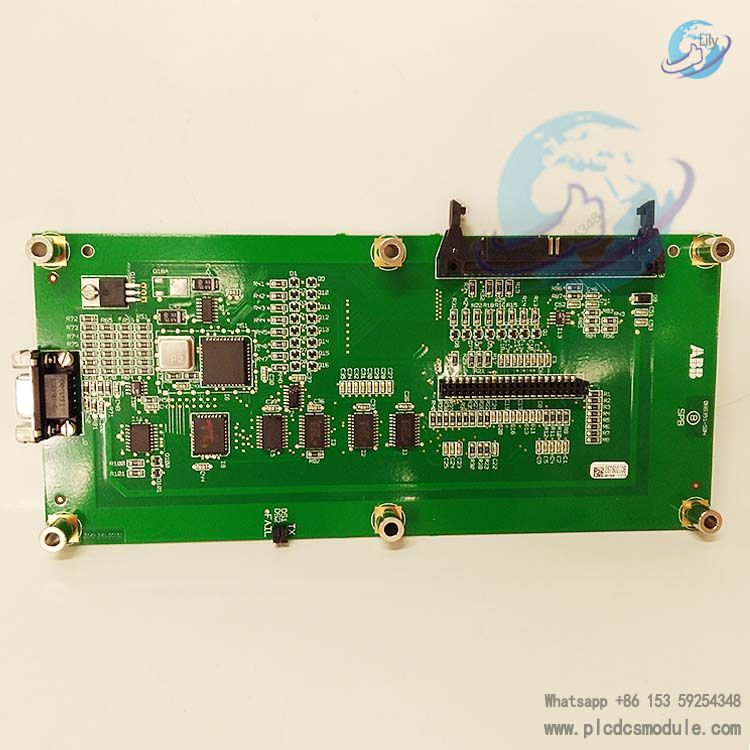

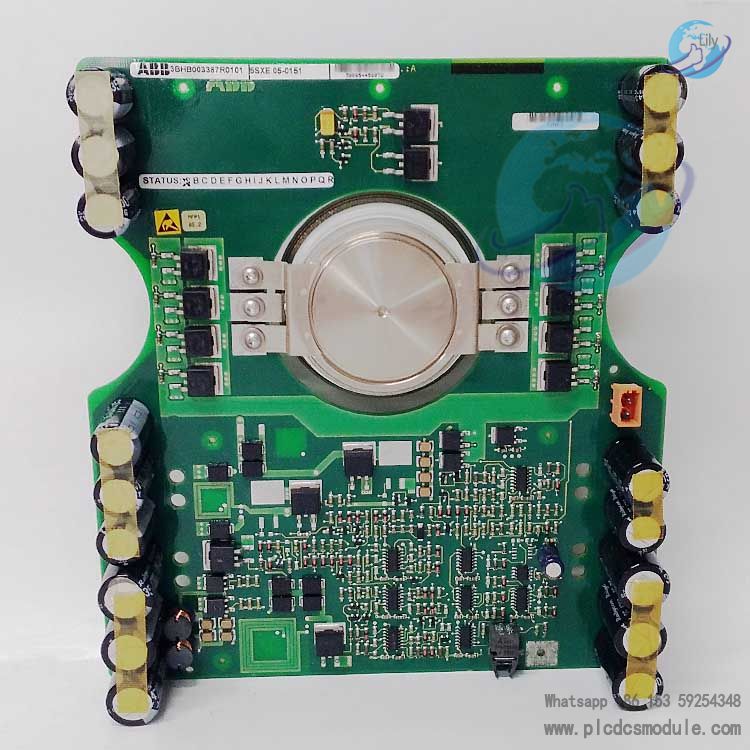

The ABB

UDC920BE01 3BHE034863R0001 High-Voltage Control

Board Module is a high-performance control unit specifically designed for 3kV-35kV high-voltage power systems. It integrates high-precision signal acquisition, complex logic operation, and high-voltage equipment driving functions, and is widely applied in critical fields such as substations, high-voltage motor control, and power transmission.

Serving as the "neural center" of high-voltage systems, this module enables precise control and real-time status monitoring of equipment like high-voltage circuit breakers, disconnectors, and transformers, ensuring the safe, stable, and efficient operation of high-voltage systems.

It adopts a reinforced insulation design and redundant architecture, has passed international safety certifications for high-voltage equipment, and can work reliably for a long time in harsh environments such as strong electromagnetic interference and high humidity. It is an ideal solution for the automated control of large-scale industrial high-voltage systems.

Core Features and Advantages

1. Dedicated Control Capability for High-Voltage Systems

- Wide Voltage Level Adaptation: Supports the full range of 3kV-35kV high-voltage systems and is compatible with high-voltage equipment of different capacities (10MVA-500MVA), enabling flexible deployment without hardware adjustments.

- High-Precision Signal Acquisition: Equipped with a built-in 24-bit high-precision ADC converter, it supports signal acquisition of high-voltage side voltage (0-50kV) and current (0-2000A), with a measurement accuracy of ±0.05% FS, meeting the metering-level requirements of power systems.

- Fast Control Response: Powered by a dual-core 32-bit industrial processor (200 MIPS), the control cycle can be as low as 1ms, ensuring rapid response to high-voltage faults (e.g., short-circuit protection action time < 20ms).

- Professional High-Voltage Algorithms: Built-in dedicated control logic for high-voltage equipment (such as circuit breaker opening/closing sequence control and transformer on-load tap-changer algorithm), complying with power industry standards including IEC 61850 and GB/T 14285.

2. Enhanced Safety and Insulation Design

- Multi-Level Insulation Protection: Adopts a reinforced insulation structure with a creepage distance > 40mm, electrical clearance > 25mm, and insulation withstand voltage > 50kV (for 1 minute), meeting the DL/T 478 standard for high-voltage equipment control.

- Comprehensive Fault Protection:

- Hardware-Level: Overvoltage (60kV), overcurrent (3000A), and arc protection, with a response time < 1μs;

- Software-Level: Operation interlocking for high-voltage equipment, self-diagnosis of status, and protection against communication anomalies;

- System-Level: Links with high-voltage protection devices to achieve "control-protection" integration.

- EMC Optimization: Passes the EN 61000-6-2/4 EMC test for high-voltage environments, featuring strong anti-interference capability and maintaining signal stability during high-voltage switch operations.

3. High-Reliability Redundant Architecture

- Full-System Redundant Configuration: Supports 1+1 hot redundancy for control boards, dual power backup, and communication link redundancy, with a switching time < 20ms. It meets the "zero downtime" operation requirement of high-voltage systems, with a Mean Time Between Failures (MTBF) > 1,200,000 hours.

- Wide-Temperature Stable Operation: Uses military-grade components (-40℃~+85℃), and the PCB board is coated with special three-proof paint (salt spray resistant, mildew proof), adapting to the installation environment of outdoor high-voltage cabinets (IP54 protection level).

- Vibration and Shock Resistance: Complies with IEC 60068-2-6 (vibration) and IEC 60068-2-27 (shock) standards, and can be installed in high-vibration locations such as substations and rolling mills.

4. Smart Grid Compatibility and Communication

- Grid-Level Communication Interfaces:

- 2 channels of Gigabit industrial Ethernet (supporting IEC 61850-8-1 MMS and GOOSE messages), enabling seamless connection with substation automation systems;

- 1 channel of Profibus DP (for connecting local intelligent devices);

- 1 channel of IRIG-B code interface (time synchronization accuracy ±1μs), meeting the requirements of Sequence of Events (SOE) recording in power systems.

- Data Recording and Analysis: Built-in 64MB data storage, which can record key operating data for more than 1 year (sampling interval 10ms). It supports waveform recording for 10 seconds before and 5 seconds after a fault, facilitating accident tracing and analysis.

- Remote Monitoring Support: Compatible with the ABB Ability™ Power Cloud Platform, supporting remote parameter configuration, status monitoring, and fault diagnosis, reducing operation and maintenance costs.

Technical Specifications

| Category | Detailed Parameters |

|---|

| Basic Information | Model: UDC920BE01

Order Number: 3BHE034863R0001

Product Type: High-Voltage Control Board Module

Applicable Systems: 3kV-35kV high-voltage power systems, substation automation, high-voltage motor control |

| Processor & Storage | Processor: Dual-core 32-bit industrial CPU (200 MIPS)

Program Storage: 32MB Flash (expandable to 64MB)

Data Storage: 64MB RAM (with super capacitor backup, data retention for >72 hours after power failure) |

| Signal Acquisition & Control | Analog Input: 8 channels (high-voltage side voltage/current signals, accuracy ±0.05% FS)

Digital Input: 32 channels (high-voltage equipment status signals, response time <1ms)

Digital Output: 16 channels (drives high-voltage equipment operating mechanisms, capacity 5A/250V AC)

Control Cycle: Configurable, minimum 1ms

SOE Resolution: 1ms |

| Communication Interfaces | Industrial Ethernet: 2×1000BASE-T (supports IEC 61850, Modbus TCP/IP)

Fieldbus: 1×Profibus DP (transmission rate 12Mbps)

Time Synchronization: 1×IRIG-B code input (DC level/TTL)

Debugging Interface: 1×USB 2.0 Type B |

| Power Requirements | Operating Voltage: 24V DC ±15% (redundant dual power input)

Power Consumption: ≤18W during normal operation, ≤25W under maximum load

Power Protection: Overvoltage (36V DC), overcurrent (2A), reverse connection protection |

| Environmental & Mechanical Parameters | Operating Temperature: -25℃~+70℃

Storage Temperature: -40℃~+85℃

Relative Humidity: 5%~95% (no condensation)

Insulation Withstand Voltage: >50kV (1 minute, DC)

Creepage Distance/Electrical Clearance: >40mm/>25mm

Dimensions (Width × Height × Depth): 220mm×160mm×100mm

Weight: Approximately 1.8kg

Protection Level: IP20 (board level), compatible with IP54/IP65 high-voltage cabinets |

Installation and Configuration Guide

1. Installation Requirements

Safety Specifications

- Installers must hold a high-voltage electrician qualification certificate. Before operation, confirm that the high-voltage system is powered off and grounded, and use insulated tools.

Mechanical Installation

- Install the module on the dedicated guide rail or slot inside the high-voltage control cabinet. Maintain a distance of ≥150mm from high-voltage components to ensure insulation safety.

- Fix the module with M4 insulated screws (torque: 1.0Nm) to avoid reduced insulation caused by metal contact.

- For redundant configuration, maintain a distance of ≥50mm between the two control boards to ensure heat dissipation and independent wiring.

Electrical Connection

- Strictly separate the wiring of the control power supply and high-voltage circuit, and use cables of different colors for distinction (blue is recommended for control cables).

- Use shielded twisted-pair cables (cross-sectional area ≥0.75mm²) for signal cables, and ground the shield layer at one end (grounding resistance <4Ω).

- Route Ethernet and fieldbus cables through metal conduits to avoid electromagnetic interference.

2. Configuration and Debugging

Configuration Tools

- Use ABB Power Automation Studio software (Version V3.2 or above).

Basic Configuration Steps

- Connect the debugging computer to the control board via USB or Ethernet to establish a secure communication link.

- Import the system configuration file corresponding to the voltage level (e.g., 10kV substation, 35kV motor control).

- Configure signal ranges, control logic, protection thresholds, and communication parameters (IEC 61850 address, GOOSE configuration).

- Perform offline testing (without high voltage) to verify the accuracy of control output and signal acquisition.

High-Voltage Joint Debugging

- Gradually apply high voltage (20% → 50% → 100% rated voltage) and monitor sampling data and equipment status.

- Test fault protection functions (e.g., simulate overcurrent, overvoltage) to confirm that the protection action time and logic are correct.

- Verify the redundant switching function to ensure no data loss or control interruption during the active-standby board switchover.

Application Scenarios

With its professional high-voltage control capabilities, the ABB UDC920BE01 3BHE034863R0001 High-Voltage Control Board Module is widely applied in power and industrial high-voltage systems:

Customers who purchased this product are also browsing the following products:

ABB XV C772 A101 3BHE032285R0101 HVD- BOARD

ABB UUD148AE01 3BHE014185R0001 Current Transducer Control Board

Honeywell CC-PCF901 51405047-175 Control Firewall Module

GE IS200TRLYH1BHH Mark Vie Relay Output Terminal Board

3005319639

3005319639