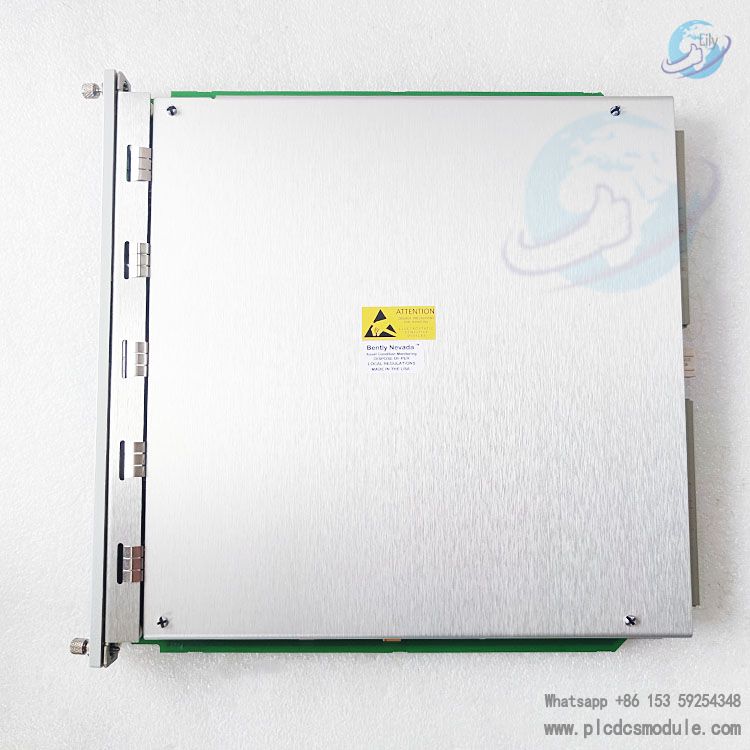

Bently Nevada 3500/22M 138607-01 Transient Data Interface Module old version.The Bently Nevada 3500/22M 138607-01Transient Data Interface (TDI) Module serves as the connection bridge between the 3500 Monitoring System and GE's System 1 Machinery Management Software, integrating the functions of the 3500/20 Rack Interface Module and communication processors like TDXnet. Installed in the RIM slot (Slot 1) of the 3500 rack right next to the power supply, it collaborates with M-series monitors such as the 3500/40M and 3500/42M to continuously collect both steady-state and transient waveform data, which are then transmitted to the host software via Ethernet. It also has the capability of static data collection, and with the aid of an optional channel-enabled disk, it can gather dynamic or transient data as well. Supporting multiple communication protocols and interfaces, this module has a power consumption of 10.5 watts, along with various environmental restrictions and compliance certifications. When ordering, different configuration options are available, and information on accessories such as the dynamic data-enabled disk and spare parts is provided.

Bently Nevada 3500/22M 138607-01 Transient Data Interface Module old version.The Bently Nevada 3500/22M 138607-01Transient Data Interface (TDI) Module serves as the connection bridge between the 3500 Monitoring System and GE's System 1 Machinery Management Software, integrating the functions of the 3500/20 Rack Interface Module and communication processors like TDXnet. Installed in the RIM slot (Slot 1) of the 3500 rack right next to the power supply, it collaborates with M-series monitors such as the 3500/40M and 3500/42M to continuously collect both steady-state and transient waveform data, which are then transmitted to the host software via Ethernet. It also has the capability of static data collection, and with the aid of an optional channel-enabled disk, it can gather dynamic or transient data as well. Supporting multiple communication protocols and interfaces, this module has a power consumption of 10.5 watts, along with various environmental restrictions and compliance certifications. When ordering, different configuration options are available, and information on accessories such as the dynamic data-enabled disk and spare parts is provided.

data sheet:

![]() Bently Nevada 3500/22M 138607-01 Transient Data Interface Module.pdf

Bently Nevada 3500/22M 138607-01 Transient Data Interface Module.pdf

Technical Specifications of Bently Nevada 3500/22M 138607-01:

Power Consumption and Physical Characteristics

Power consumption: 10.5 watts.

The dimensions of the TDI module are 241.3 mm x 24.4 mm x 241.8 mm, and it weighs 0.91 kg.

The dimensions of the I/O module are 241.3 mm x 24.4 mm x 99.1 mm, and it weighs 0.20 kg.

The TDI module occupies one full-height front slot, while the I/O module occupies one full-height rear slot.

Environment and Certification

Operating temperature:-30°C to+65°C.

Storage temperature:-40°C to+85°C.

Humidity: 95% (non-condensing).

It is certified according to relevant CE Mark directives, the EN 61010-1 safety standard, etc. It also has certifications for hazardous areas such as CSA/NRTL/C and European ATEX.

Ordering Information for Bently Nevada 3500/22M

Configuration Options

The order number is 3500/22-AXX-BXX-CXX.

A represents the type of transient data interface (01 for standard type, 02 for TMR type).

B represents the type of I/O module (01 for 10Base-T/100Base-TX Ethernet, 02 for 100Base-FX fiber-optic Ethernet).

C represents the agency approval option (00 for none, 01 for CSA/NRTL/C, 02 for CSA/ATEX).

Accessories and Spare Parts

The 3500/22M dynamic data-enabled disk can support different numbers of steady-state and transient points. The sum of the two should not exceed 672, and one disk can support multiple TDIs.

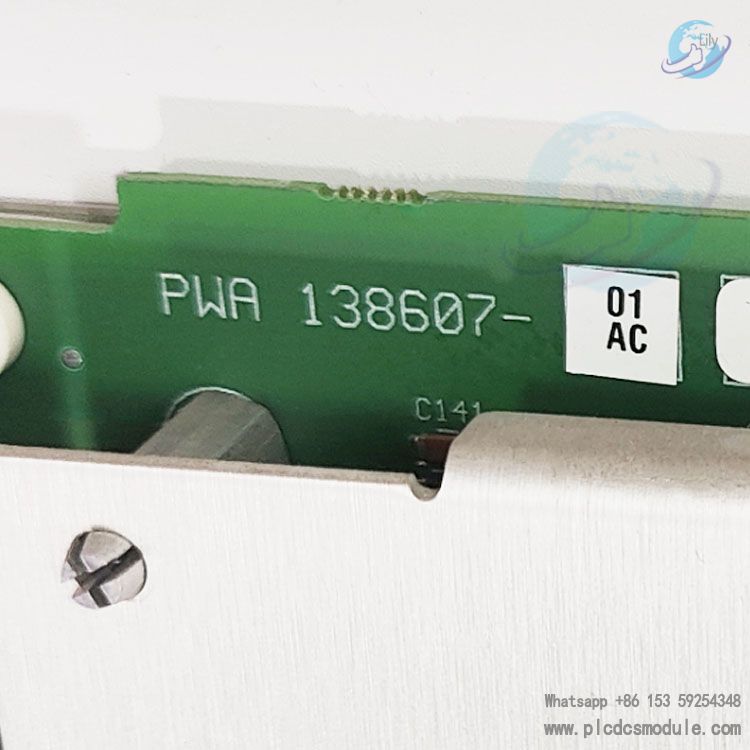

Various Ethernet cables and spare parts are provided, such as the standard transient data interface module (138607-01).

Key Questions

What are the unique features of the 3500/22M TDI module in data collection?

Answer: It can not only perform standard static data collection but also collect dynamic or transient data through an optional channel - enabled disk. It supports four 3500 system Keyphasor signals and can adapt to different speed ranges according to the number of dynamic channels, with a maximum speed of up to 100,000 rpm. The speed interval for collecting start - up/shutdown data can be independently programmed. It can initiate transient data collection within a programmable window based on the machine speed, and the number of data collected is only limited by the module's memory. Alarm data collection includes static values and waveform data at different time intervals before and after the alarm, providing rich information for equipment status analysis.

What are the communication interfaces of the 3500/22M TDI module, and what are their respective characteristics?

Answer: The front - panel communication interface is RS232, with a maximum baud rate of 115.2 kbaud. The 10Base - T/100Base - TX Ethernet I/O interface supports auto - sensing, complies with the IEEE802.3 standard, is used for Ethernet communication, uses an RJ - 45 interface, and has a maximum cable length of 100 meters. The 100Base - FX Ethernet I/O interface is a fiber - optic interface, complies with the IEEE802.3u standard, uses an MT - RJ fiber - optic connector, and has a maximum cable length of 2000 meters, which is suitable for long - distance and high - speed data transmission scenarios.

What points should be noted when ordering the 3500/22M TDI module?

Answer: In the order number 3500/22 - AXX - BXX - CXX, A, B, and C represent different configuration options respectively, which need to be selected according to actual needs. For example, if it is used for standard monitoring applications, select 01 for A; if a fiber - optic Ethernet I/O module is required, select 02 for B. The sum of the steady - state points and transient points of the 3500/22M dynamic data - enabled disk cannot exceed 672, and one disk can support multiple TDIs. In addition, suitable Ethernet cables and spare parts need to be selected according to the actual usage scenario.

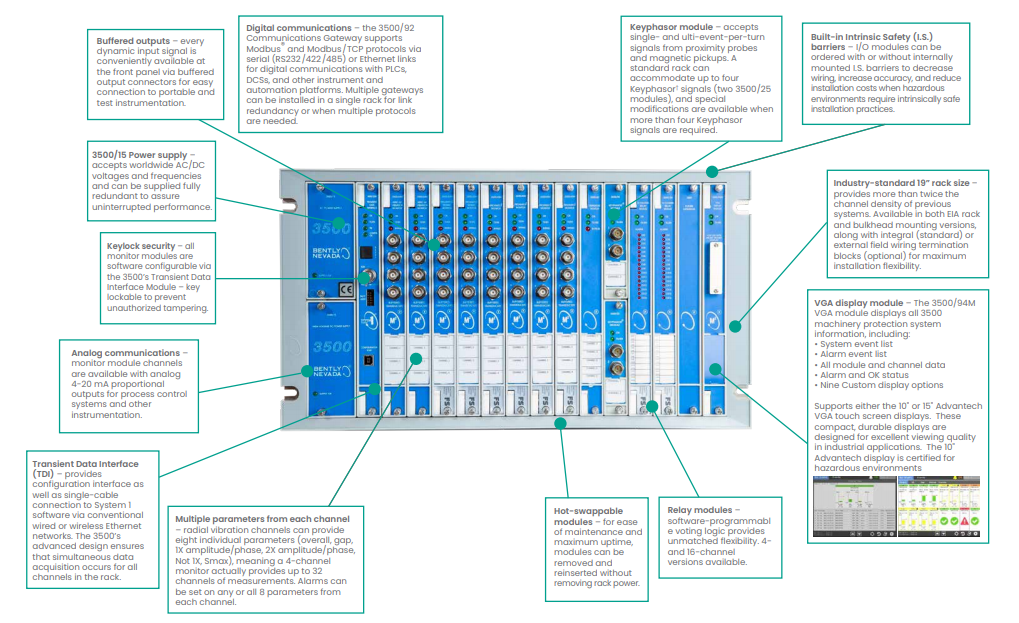

The Bentley 3500 system architecture is a complex yet advanced framework. It most likely integrates state-of-the-art components and technologies to achieve high-efficiency performance. This architecture may be equipped with a powerful processing unit, high-speed data transmission capabilities, and a robust network system. It might also be furnished with intelligent control and monitoring systems to ensure smooth operation and rapid error detection. The design probably adopts a modular approach, which is easy to expand and customize to meet specific user requirements. In summary, the Bentley 3500 system architecture is designed to ensure reliability and flexibility for various applications.

The main configuration module models of the Bentley 3500 safety system are as follows:

Rack Interface Module (RIM): 3500/20

This is the basic interface of the 3500 rack, supporting Bentley Nevada's proprietary protocol for rack configuration and retrieving information from devices. It must be placed in the first slot of the rack (near the power supply).

Power Supply Module

For example, the 3500/15, which provides power for the system.

Keyphasor Module: 3500/25

This is an optional module.

Monitoring Modules

Such as the 3500/40M Proximitor Displacement Monitor, 3500/42M Displacement/Velocity/Acceleration Monitor, 3500/45 Differential Expansion/Axial Position Monitor, 3500/50 Speed Module, 3500/53 Overspeed Detection Module, 3500/60 and 3500/61 Temperature Monitors, 3500/64M Dynamic Pressure Monitor, 3500/72M Piston Rod Position Monitor, 3500/77M Cylinder Pressure Monitor, etc. These are used to monitor various parameters.

Relay Modules

Including the 3500/32 Relay Module, 3500/34 Triple Redundant Relay Module, etc.

Communication Gateway Module

Such as the 3500/92, which is used to implement the digital communication function of the system.

Different application scenarios may require different module combinations to meet specific monitoring needs. In practical applications, selection and configuration should be made according to the specific situation.

Customers who viewed this product also viewed the following products:

SIEMENS 6SL3325-1TG41-0AA3 inverter motor module

HONEYWELL EG1033AC01 EG Flame Amplifier (LG Series)

PIONEER MAGNETICS PM3326B-6-1-2-E 80026-529-01 Power Supply module

GE VMIVME-7750-834 Pentium III 933 MHz Processor CPU Module

3005319639

3005319639