Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The

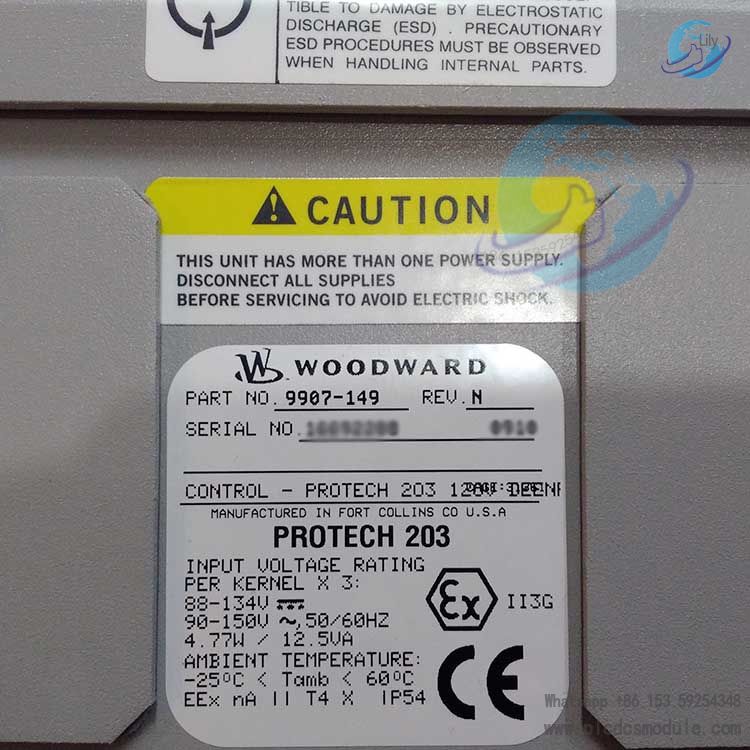

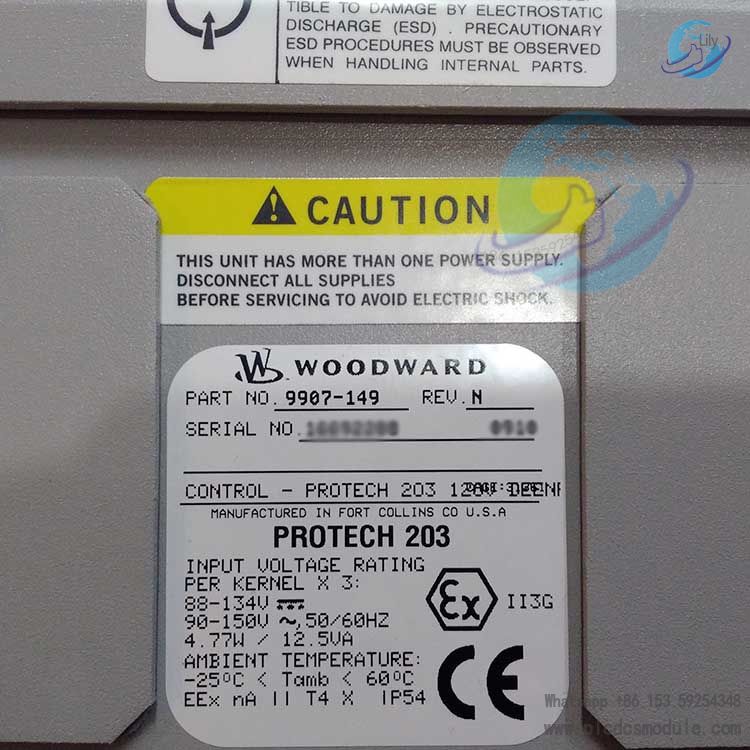

9907-149 is a three-channel electronic overspeed trip device launched by

Woodward. It belongs to the ProTech 203 Overspeed Protection System family and is specifically designed for rotating machinery such as steam turbines, gas turbines, and generators. Its core function is to real-time monitor the speed of the prime mover; when the speed exceeds the preset trip threshold, it triggers a safe shutdown action to prevent equipment damage or safety accidents caused by overspeed.

This device adopts the "2-out-of-3" voting logic. It collects signals from three magnetoelectric speed sensors (MPUs) through three independent speed detection units (Unit A/B/C) respectively, and only triggers a trip when at least two units detect overspeed. This effectively avoids false actions or failure to act caused by the fault of a single sensor or unit, meeting the requirements of industrial safety integrity. Meanwhile, the 9907-149 supports a wide-range power input of 120 VAC/DC, which is compatible with power supply needs in multiple scenarios. It is widely used in the protection of key rotating equipment in fields such as electric power, petrochemical industry, and energy.

DATA SHEET

9907-149.pdf

9907-149.pdf

Performance Parameters

1. Core Electrical and Control Parameters

2. Environmental and Physical Parameters

Application Fields

With its high reliability and wide adaptability, the WOODWARD 9907-149 has become a core component for overspeed protection of rotating machinery, mainly applied in the following fields:

1. Power Industry

- Steam turbines in thermal power units: Monitors the speed of the high and intermediate pressure rotors of steam turbines. When the grid load drops sharply or steam parameters are abnormal, causing the speed to exceed 110% of the rated value (e.g., a trip threshold of 3300 rpm for a 3000 rpm unit), it triggers a trip to close the governor valve and main steam valve.

- Gas turbine generator sets: Adapts to high-speed rotors of gas turbines (e.g., 3600 rpm or higher), preventing overspeed caused by fuel fluctuations and compressor surges to ensure the safety of the unit and the power grid.

2. Petrochemical Industry

- Centrifugal compressors: Protects the compressor rotors in natural gas transmission and catalytic cracking units, avoiding overspeed caused by sudden changes in process load (e.g., sudden closure of the outlet valve) and preventing damage to compressor impellers.

- Large process pumps: Monitors the speed of crude oil and refined oil transfer pumps, preventing seal failure and bearing burnout caused by pump shaft overspeed.

3. Energy and Power Sector

- Steam turbines for biomass power generation: Adapts to speed fluctuations caused by unstable combustion of biomass fuels, ensuring stable unit operation through precise overspeed protection.

- Steam turbine units supporting waste heat boilers: Matches scenarios with fluctuating waste heat steam parameters, preventing overspeed trips of steam turbines caused by sudden increases in steam volume.

Advantages and Features

1. High Safety and Reliability

- "2-out-of-3" voting logic: Three independent detection units collect MPU signals respectively. A trip is only triggered when two or more units determine overspeed, avoiding false actions or failure to act caused by a single fault (e.g., MPU disconnection, unit hardware failure) and complying with industrial safety design specifications.

- Multiple fault protection: Supports MPU signal loss detection (triggers an alarm or trip when the signal is suddenly lost, configurable via parameters), CPU fault monitoring (with independent LED indication), and EEPROM data verification (prevents damage to configuration data), fully covering hardware and signal faults.

- Wide temperature range and anti-interference capability: The operating temperature range of -25°C to +60°C is suitable for harsh environments such as power plant steam turbine rooms and petrochemical compressor rooms; it complies with the EN 61000-6-2 industrial EMC standard to resist electromagnetic interference generated by motors and frequency converters.

2. Flexible Configuration and Operation

- Wide power supply adaptability: 120 VAC/DC dual-mode input eliminates the need for additional power converters, adapting to different factory power supply systems (e.g., AC power or DC control cabinet power).

- Customizable parameters: Through panel buttons and an LCD display, parameters such as trip speed (250-25,000 rpm), MPU fault timeout (1 sec-533 min 20 sec), and number of teeth of the MPU monitoring gear (20-120 teeth) can be configured to adapt to different types of prime movers.

- Online test function: Supports a built-in frequency generator to simulate overspeed signals, enabling testing of the trip logic of a single unit without stopping the prime mover, thus avoiding production interruption.

3. Convenient Maintenance and Diagnosis

- Visual status indication: The panel is equipped with LED lights for "Power (P)", "Tripped (TRIPPED)", "MPU Fault (MPU FAIL)", "CPU Fault (CPU FAIL)", etc., enabling quick identification of fault types; the LCD displays real-time speed, peak speed, and trip causes (e.g., "MPU>TRIP SETPT", "MPU FAIL TIMEOUT").

- Modular replacement: A single detection unit (including the power board and display board) can be replaced independently without stopping the machine (the other two units continue to work), reducing maintenance downtime.

- Remote reset and alarm: Supports a remote reset interface (dry contact input) and alarm output (normally closed/normally open contacts), facilitating integration into the plant DCS system for remote monitoring and operation.

Working Principle

The WOODWARD 9907-149 operates with a core process of "signal acquisition - speed calculation - logic judgment - trip output", which is detailed as follows:

- Signal Acquisition: Three MPUs (Magnetoelectric Speed Sensors) are installed near the prime mover's gearbox or rotor. They detect the alternating signals generated by the alternating tooth crests and tooth troughs of the gear, convert the rotational speed into frequency signals, and transmit these signals to the three detection units (Unit A/B/C) of the 9907-149 respectively.

- Speed Calculation: Each unit is equipped with a built-in microcontroller. Based on the MPU input frequency and the preset "number of gear teeth", it calculates the current speed (Speed = Frequency × 60 / Number of Gear Teeth). At the same time, it updates the "peak speed" (stored in non-volatile memory, which is not lost when power is cut off).

- Logic Judgment: Each unit compares the current speed with the "trip speed set value". If the current speed exceeds the threshold, it is determined as "overspeed" and a unit-level trip signal is output. At the system level, through the "2-out-of-3" voting logic, when ≥2 units output overspeed signals, a system trip is triggered.

- Trip Output: The system drives the internal interposing relay to act, switching the state of the output contacts (e.g., in the de-energize-to-trip mode, the relay is energized under normal conditions and de-energized when a trip is triggered). This in turn controls the prime mover's shutdown actuator (such as closing the fuel valve or cutting off steam supply).

- Fault Handling: If MPU signal loss is detected (e.g., frequency drops sharply from > 120 Hz to < 100 Hz) or the MPU fault set speed is not reached within the timeout period (e.g., the minimum speed is not reached within the set time during startup), an alarm or trip is triggered (configured according to the "TRIP ON MPU FAILURE" parameter).

Customers who purchased this product are also browsing the following products:

woodward 8237-1600 ProTech-GII Overspeed Protection Device

Woodward 8273-140 2301D Load Sharing Speed Control

GE IC698CPE020-JX PACSystems RX7i Central Processing Unit

ABB UUD148AE02 3BHE014185R0002 | Current Transducer

3005319639

3005319639