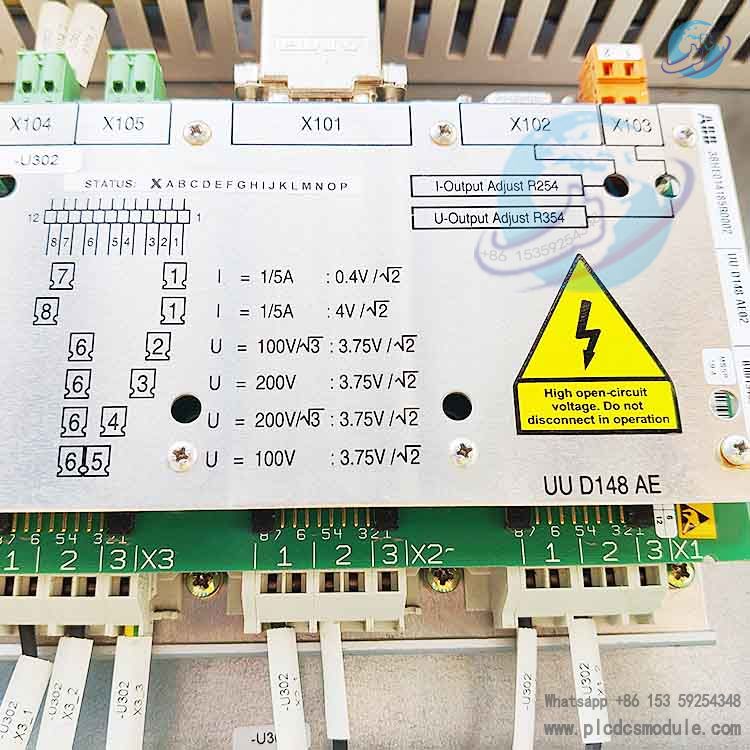

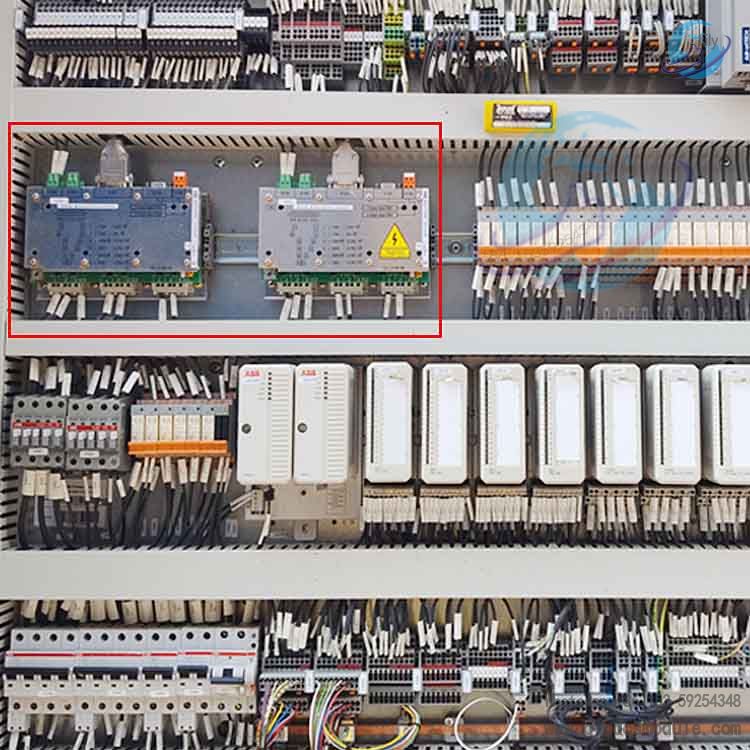

ABB UUD148AE02 3BHE014185R0002 Current Transducer Control Board UU D148 AE. Model Name: UU D148 AE02: 1A, which clearly indicates that it belongs to a specific series of current sensor control boards by ABB. Among them, "1A" may be associated with specific current measurement-related parameters or design specifications, further specifying the product characteristics.

Country of Origin: Sweden (SE), a country with advanced industrial technology.

Net Weight: 1.475 kg

Product Status: The product is brand new.

Core Functions

Current Signal Conditioning and Conversion:

The control board features strong compatibility and can interface with various types of current sensors available on the market. It is fully compatible with both common electromagnetic current sensors and advanced Hall effect current sensors. For the original current signals collected by sensors, the control board performs precise amplification and filtering operations. The internally integrated high-performance operational amplifier can accurately amplify weak current signals to an amplitude range suitable for subsequent processing, ensuring that key information in the signals is not lost due to excessively small amplitudes. Meanwhile, advanced filtering circuits are employed to effectively remove noise interference from the signals, which may originate from electromagnetic interference in industrial environments, power supply fluctuations, etc., thus ensuring signal purity and providing a solid foundation for accurate subsequent processing.

After signal conditioning, the control board can accurately convert current signals into standard digital or analog outputs. For analog input modules commonly used in industrial control systems, it can convert current values into 4-20mA analog signal outputs. This standard analog output format is widely used in the industrial automation field, facilitating direct connection with various analog input modules to achieve seamless data transmission and interaction. With the increasing popularity of digital control systems, it can also convert current signals into digital signals for high-speed, high-precision data transmission through digital communication interfaces, meeting the stringent requirements of digital control systems for data transmission speed and accuracy, and ensuring that the system can acquire current information in real-time and accurately, enabling timely and precise control decisions.

Real-time Monitoring and Fault Diagnosis:

Real-time monitoring of current signals is one of the core functions of this control board, which can continuously and accurately track key parameters such as current amplitude and phase. Taking an industrial motor drive system as an example, during normal operation, the stator current of the motor will remain within a reasonable range with stable phase relationships. Once the motor experiences abnormal operating conditions such as overload or locked rotor, the current amplitude will increase rapidly and the phase may also change. At this point, the control board can quickly detect these abnormal changes in current parameters and promptly trigger an alarm mechanism, sending clear and accurate fault signals to the connected motor driver or upper-level control system through internal signal processing circuits and communication interfaces. This allows operators to be immediately informed of abnormal motor operation and take corresponding measures, such as reducing motor speed or stopping motor operation, to prevent motor damage due to prolonged overload or locked rotor, effectively improving the operational reliability of the motor drive system and extending equipment service life.

In addition to monitoring external current signals, the control board also has a comprehensive self-diagnostic function. It can regularly conduct comprehensive and in-depth inspections of its own hardware status and communication links. Through a built-in efficient self-inspection program, the control board checks each electronic component for normal operation, including whether the performance of key components such as resistors, capacitors, and chips is within the normal range, and whether communication interfaces have issues such as data transmission errors or communication interruptions. If a fault is detected during self-inspection, the control board will immediately record detailed fault codes, which act like precise "keys" to help technicians quickly locate the fault point. At the same time, the control board will promptly inform operators of fault information through specific communication methods such as RS-485 communication interface or Ethernet interface, greatly improving the efficiency of fault detection and repair, ensuring stable operation of the entire system, and reducing system downtime and production losses caused by control board failures.

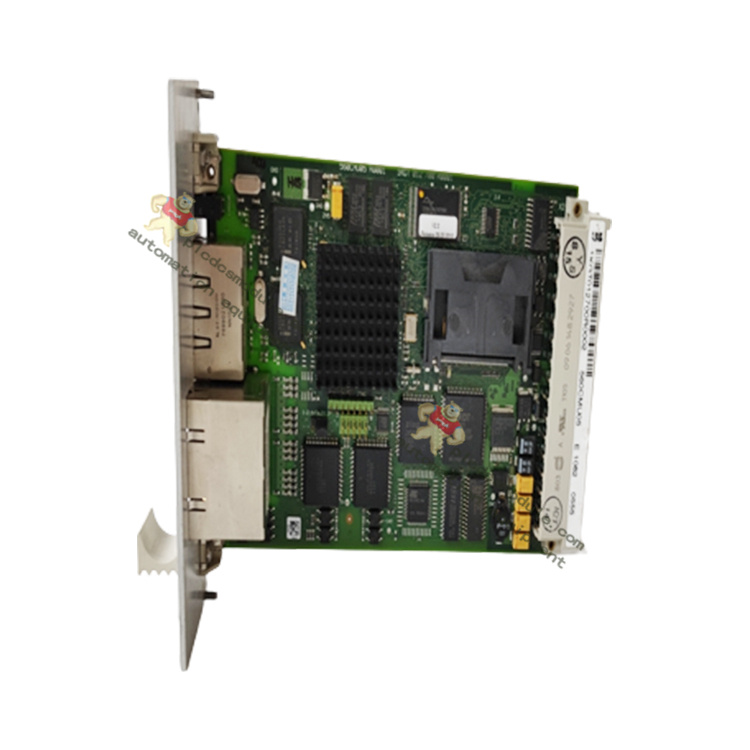

System Communication and Integration:

In the field of industrial automation, communication and integration between devices are crucial. The control board supports multiple communication protocols, among which the RS-485 communication interface combined with Modbus RTU protocol provides strong support for convenient data interaction with other industrial automation equipment. The RS-485 communication interface has advantages such as long transmission distance and strong anti-interference capability, making it very suitable for data transmission needs in industrial environments. In factory automation production lines, the control board can easily transmit current monitoring data to PLCs (Programmable Logic Controllers) through the RS-485 bus. As one of the core devices in industrial automation control systems, PLCs can conduct further in-depth analysis and processing of these current data, make precise equipment control decisions based on production process requirements and equipment operating status, such as adjusting motor speed and controlling valve opening, to achieve automated and intelligent control of the entire production process, improving production efficiency and product quality.

Some models of the control board also feature an Ethernet interface and support industrial Ethernet communication protocols such as Profinet. The Ethernet interface has significant advantages of high speed and strong large data transmission capability, making it suitable for application scenarios with extremely high real-time requirements. In power monitoring and control systems in smart grids, a large amount of current data needs to be transmitted to the upper monitoring center in real-time and accurately for comprehensive and real-time monitoring and analysis of grid operating status. At this time, the Ethernet interface of the control board can transmit current data to the upper monitoring center quickly and stably at a high transmission rate of 100Mbps, with a communication cycle as low as ≤1ms, ensuring that the grid monitoring system can promptly obtain the latest current information, respond quickly to abnormalities in the power grid, and ensure the safe and stable operation of the power grid.

1. Input Signal Characteristics

Current Measurement Range: Basic 0-500A; extendable to 0-1000A+ via sensor configuration or range switching, adapt to diverse power distribution scenarios.

Frequency Response Range: Handles 50/60Hz power frequency signals; covers 0-1kHz for non-power frequency applications (e.g., variable-frequency equipment).

2. Output Signal Parameters

Analog Output: Standard 4-20mA DC (load ≤500Ω); optional 0-10V DC (load ≥10kΩ) for flexibility.

Digital Output: 2 dry contacts (24V DC, 1A rated), usable for triggering alarms/relays (e.g., overcurrent protection).

Digital Communication Output: Modbus-RTU (baud rate 9600-115200bps, 8 data bits, 1 stop bit, optional parity); Profinet-enabled models: 100Mbps Ethernet, ≤1ms communication cycle.

3. Power Supply Requirements

Main Power: 24V DC (±10% range: 21.6-26.4V DC), ≤3W low power consumption.

Backup Power (Optional): 110V AC/220V AC with dual-power redundancy, for high-reliability scenarios (e.g., nuclear power, chemical plants).

4. Environmental Adaptability

Operating Temperature: Standard -25℃~+70℃; optional wide-temperature version -40℃~+85℃.

Storage Conditions: -40℃~+85℃, 5%-95% RH (non-condensing); IP20 dust protection (use with protective cabinets for waterproofing).

EMC Performance: Complies with EN 61000-6-2 (resists 80MHz-1GHz, 10V/m radiation) and EN 61000-6-4 (resists 0.15-80MHz, 3V conduction interference).

Product Advantages

High-Precision Measurement and Control: Precision is a key indicator of product performance in the field of current measurement and control. This control board adopts advanced signal processing algorithms and strictly selected high-precision electronic components, ensuring extremely high accuracy throughout the entire measurement range. For example, within the rated current range, the accuracy can reach 0.1% FS (Full Scale Error)—this means that for a measurement range with a full scale of 500A, the measurement error can be controlled within 0.5A. This high-precision measurement capability provides reliable data support for applications with strict current accuracy requirements. Meanwhile, its linearity error is ≤0.05% FS, meaning the error between the actual measured value and the ideal linear value is minimal when the current signal changes from the minimum to the maximum. This ensures the accuracy and stability of measurement results, enabling it to provide precise data in both small-current measurement and large-current monitoring scenarios, meeting the needs of applications with high current accuracy requirements such as power monitoring for precision instruments and high-precision motor control, and ensuring the accurate operation of the system.

The control board also boasts an outstanding advantage of fast response to current signals, with a response time of ≤10μs. In power systems, current changes are often very rapid—for instance, a large inrush current is generated when a motor starts, and the current fluctuates sharply an instant before a short circuit occurs. The control board can quickly capture these instantaneous current changes at an extremely fast speed, making it possible to take timely protective measures. When abnormal current changes are detected, it can transmit signals to relevant equipment or systems in an extremely short time (e.g., triggering the protection circuit to cut off the power supply), preventing equipment damage caused by abnormal current, effectively improving the safety and stability of the system, and reducing the risk of economic losses and production interruptions due to equipment failures.

High Reliability and Stability:To ensure long-term stable operation in industrial environments, the electronic components inside the control board undergo strict screening and aging tests. Before entering the production process, each electronic component undergoes multiple rounds of performance testing, and only components with excellent performance and high stability are selected. After production, the entire board also undergoes long-term aging tests to simulate various actual working environments and test the operation stability of the control board under different conditions. Through such strict screening and testing processes, the electronic components are ensured to have high anti-aging and anti-interference capabilities, enabling them to maintain stable performance during long-term operation, reducing measurement errors and the probability of failures caused by component aging. In industrial automation production lines, it can achieve long-term uninterrupted operation, ensuring production continuity, improving production efficiency, and reducing equipment maintenance costs.

Equipped with a comprehensive self-diagnosis and fault protection mechanism is an important guarantee for the reliability of this control board. In addition to real-time monitoring of its own working status and abnormal current signals, it also has multiple hardware protection circuits such as overcurrent protection, overvoltage protection, and undervoltage protection. In terms of overcurrent protection, when it detects that the input current exceeds the set overcurrent threshold, the control board will quickly activate the internal current-limiting circuit to limit the current within a safe range, and at the same time trigger external protection devices (e.g., circuit breaker tripping) through output signals to prevent equipment damage caused by overcurrent. In terms of overvoltage and undervoltage protection, when it detects that the power supply voltage is too high or too low, the control board will take corresponding measures in a timely manner (e.g., cutting off the power input or sending an alarm signal) to protect internal electronic components from damage caused by abnormal voltage. These multiple protection mechanisms work together to greatly improve the reliability and stability of the system, ensuring that the control board can operate safely and stably in complex and changing industrial environments.

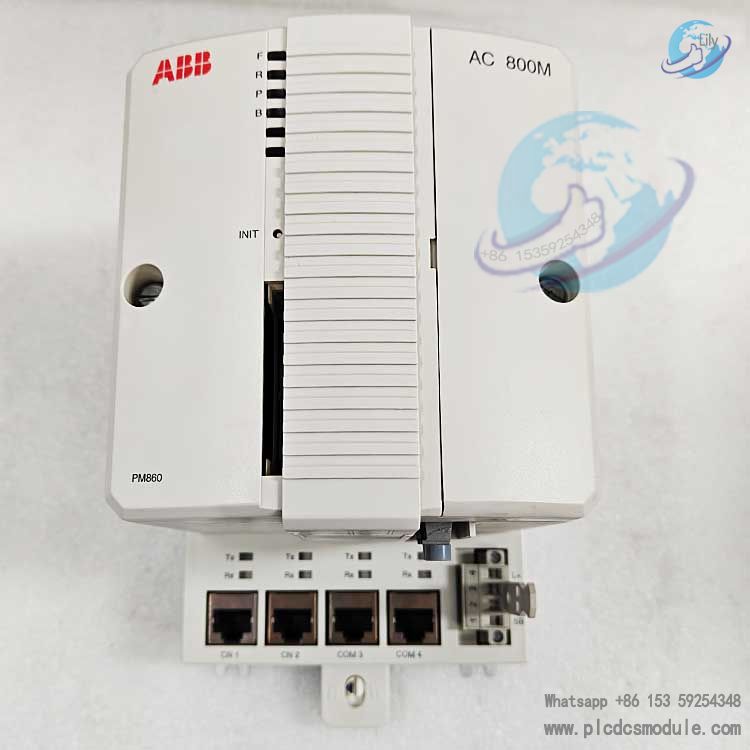

Customers who purchased this product are also browsing the following products:

ABB DASO120 57120001-EY Analog Output Board

ABB 500CPU03 1HDF700003R5122 control module

TRICONEX/Schneider DI3301 Digital Input Module

Bently Nevada 3500/42M-01-00 Proximitor Seismic Monitor

3005319639

3005319639