Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The

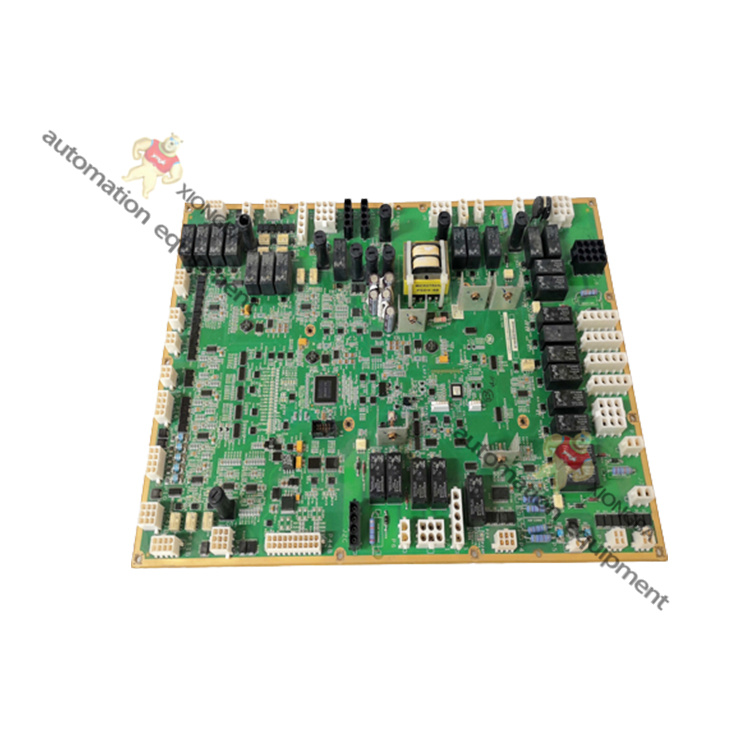

IC698CPE030 is the core Central

Processing Unit (CPU) module of the PACSystems RX7i series Programmable Automation Controllers (PACs). It was originally developed by GE Intelligent Platforms (GE IP) and later acquired by Emerson Automation along with the PACSystems RX7i series, becoming part of its product portfolio.

This module features high performance, high reliability and rich expandability as its core advantages. It is specifically designed to meet the needs of complex automation control, multi-device connectivity and system integration in industrial scenarios, and is widely used in manufacturing, energy, petrochemical and other fields.

Relevant Document Downloads:

GE IC698CPE030.pdf

GE IC698CPE030.pdf

GE IC693PBS201.pdf

GE IC693PBS201.pdf

Core Hardware Specifications

1. Processor and Memory Configuration

Processor: Equipped with a 600 MHz Pentium-M microprocessor, an industrial-grade high-performance chip. It can quickly process complex control logic and data operations, with a Boolean execution speed of 0.069 ms per 1000 Boolean contacts/coils, ensuring timely real-time control responses.Memory Specifications:

- User Memory: 64 MB, used for storing running programs and real-time data.

- User Flash Memory: 64 MB (non-volatile), enabling permanent storage of programs, configuration parameters, and documents (such as Excel, Word, PDF files), preventing data loss due to power outages.

- Additional Memory: Supports 10K user RAM + 10K non-volatile user flash memory, further enhancing data protection and temporary data processing capabilities.

- Program Block Capacity: Can accommodate 512 program blocks, with a maximum of 128 KB per program block, meeting the needs of hierarchical and complex program design.

2. Power Supply and Power Consumption

- Power Supply Voltage: Supports three commonly used industrial DC voltages: +5 VDC, +12 VDC, and -12 VDC, adapting to different on-site power supply environments.

- Backplane Current: At 5 VDC, the rated current is 3.2 A (document data) / 3.4 A (dealer supplementary data). Power consumption is reasonably controlled, compatible with industrial-grade power modules.

- Backup Protection: Supports backup battery power supply, which can prevent loss of user data and configurations in case of unexpected power outages, improving system reliability.

3. I/O Control Capacity

- Discrete I/O: Supports a maximum of 32 K bits (32,000 points), allowing connection of a large number of digital sensors and actuators (such as buttons, indicator lights, relays).

- Analog I/O: Supports a maximum of 32 K words, enabling accurate processing of analog signals such as temperature, pressure, and flow, suitable for industrial process control scenarios.

- Module Compatibility: Can seamlessly integrate Series 90-70 discrete/analog I/O modules, VME standard modules, and various communication coprocessor modules (e.g., PCM, CMM). It supports hot-swappable expansion, reducing system upgrade and maintenance costs.

Application Scenarios

With its high performance and high expandability, the GE IC698CPE030 is widely used in the following industrial fields:

- Manufacturing Industry: It serves as the core controller of production lines, enabling automated assembly, quality inspection, and robot linkage control (such as high-precision motion control) to improve production efficiency and product consistency.

- Energy Industry: It is applied in power plant automation (e.g., boiler control, steam turbine monitoring) and power transmission and distribution system management to ensure the stable operation of the power grid.

- Petrochemical Industry: It monitors and controls key process parameters such as pressure, temperature, and flow rate, realizing the safe and efficient operation of chemical processes and meeting explosion-proof and high-reliability requirements.

- Building Automation: It integrates the control of lighting, ventilation, and HVAC (Heating, Ventilation, and Air Conditioning) systems to build an intelligent building energy management platform.

- Water Treatment: It is used for the automation of processes such as aeration, sedimentation, and filtration in sewage treatment plants, and realizes real-time monitoring and adjustment in combination with water quality sensors.

Customers who purchased this product are also browsing the following products:

ABB GVC704AE01 3BHB003023P201 IGCT Module

ABB UDD406A 3BHE041465P201 PCB Board

Bently 3500/44-01-00 176449-03 Aeroderivitive GT Vibration Monitor

Foxboro FBM219 P0916RH Discrete I/O Interface Module

3005319639

3005319639