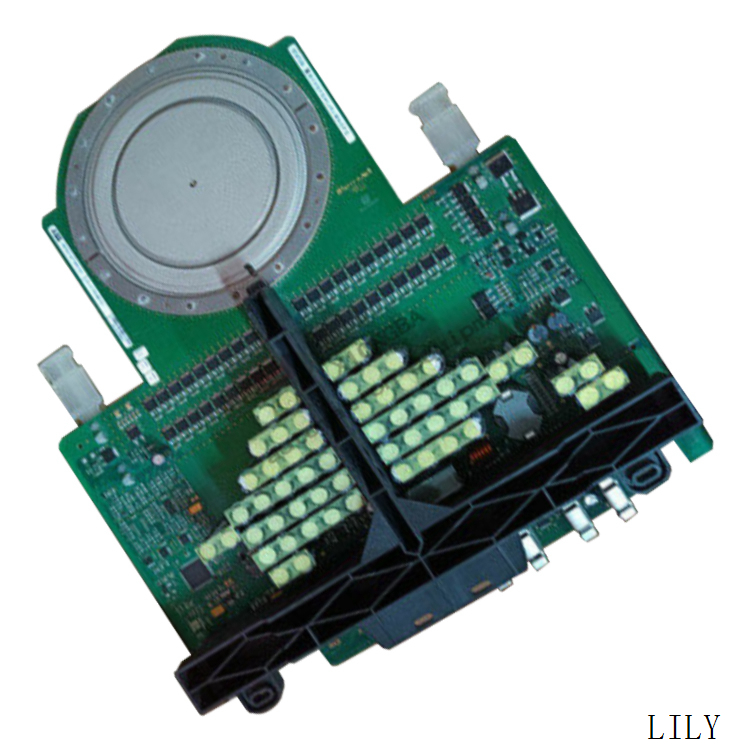

The PFEA112-20 3BSE050091R20 is a fully functional and reliably performing tension control unit belonging to the ABB Web Tension Systems series. Built on the patented Pressductor sensing technology, it adds PROFIBUS-DP fieldbus communication functionality to the basis of the PFEA111. It can accurately collect dual load cell signals and convert them into stable analog outputs and digital communication signals. Widely applicable to web tension measurement and control scenarios in industries such as papermaking, plastics, and textiles, it provides high-precision tension monitoring and closed-loop control support for continuous web processing in industrial production. It has obtained multiple international certifications including UL, CSA, and CE, and fully complies with compliance requirements such as RoHS, EMC, and low-voltage directives.

Data Sheet Download:

I. Core Functions and Technical Advantages

Precise Tension Measurement and Signal Processing

Adopt ABB's patented Pressductor® electromagnetic induction technology. It detects tension changes without physical deformation, ensuring high measurement accuracy and stability. Specific performance indicators include linear deviation < ±0.5%, hysteresis deviation < ±0.3%, and repeatability error < ±0.1%, which guarantee reliable web tension data.Support dual load cell input, capable of real-time output of sum, single-channel, and differential signals. It adapts to two measurement modes: standard roller (dual load cells) and single-side (single load cell). For single-side measurement, the signal is automatically doubled to meet different installation requirements.Offer flexible parameter configuration. Users can set measurement units (8 types including N, kN, kg, lbs), web width, and decimal places (0-5 digits). Zero calibration and tare compensation functions eliminate installation errors.

Diverse Output and Communication Capabilities

Equipped with standard analog output interfaces. The voltage output range is -5V~+11V (default 0~10V) and the current output range is 0~21mA (default 4~20mA). Support customizing output values corresponding to high/low tension and output limits, with configurable 6-level filtering (15ms~1500ms) to adapt to different response speed requirements.Built-in PROFIBUS-DP slave communication interface with RS-485 physical layer. It has a maximum transmission rate of 12Mbit/s and an address range of 0-125, supporting Class 1/2 acyclic parameter transmission. Can be quickly integrated into PLC systems via GSD files, enabling remote reading of tension data and issuance of zero calibration control commands.Realize synchronous transmission of dual-channel tension measurement values, matching the response characteristics of voltage and current outputs respectively. Support both default scaling and user-defined scaling modes to adapt to data acquisition needs of different control systems.

Flexible Installation and Environmental Adaptability

Provide two protection versions: IP20 (DIN rail mounting) and IP65 (NEMA 4 sealed enclosure). The IP20 version has dimensions of 86×136×58mm, fitting standard industrial control cabinets. The IP65 version adopts a wall-mounted design with 6 cable glands, complying with EN 60529 for protection, and can be directly installed in harsh on-site conditions.The load cell excitation circuit supports a maximum cable resistance of 5Ω, adapting to wiring distances up to 50m. Cable shielding with single-end grounding and anti-interference wiring specifications ensure signal stability in strong industrial electromagnetic environments.Cover wide operating temperature ranges: 0°C~60°C (IP20) and -10°C~80°C (IP65), with humidity tolerance of 5%~95% (non-condensing). Vibration and shock resistance meet industrial application requirements.

Convenient Debugging and Maintenance Features

Equipped with a 2×16-character multi-language display and operation buttons, supporting language switching (including Chinese and English). Parameter configuration, zero calibration, and tension calibration can be quickly completed via the panel without additional tools.Support two quick debugging modes: hanging weight calibration (automatically calculating wrap gain) and manual input of wrap gain (adjustable range 0.5-20), adapting to installation scenarios with different web wrap angles.Built-in comprehensive self-diagnostic functions. It detects faults such as flash memory errors, EEPROM errors, power failures, and abnormal load cell excitation. Status indicators and on-screen alarm messages enable quick fault location, with support for PROFIBUS communication fault early warning.

II. Key Technical Parameters

1. Power Supply and Load Cell Parameters

2. Output and Communication Parameters

3. Environmental and Physical Parameters

Application Scenarios

It is suitable for various continuous web processing equipment, including paper machines, film production lines, textile machines, printing machines, coating machines, etc. It can perform full-process tension monitoring and closed-loop control on webs such as paper, plastic films, textiles, and metal foils. This ensures uniform tension of the web during transportation and processing, avoids problems such as stretching, wrinkling, or breaking, and improves the processing accuracy and qualification rate of products.

Maintenance and Troubleshooting

1. Preventive Maintenance

2. Common Troubleshooting

Customers who purchased this product are also browsing the following products:

ABB DSAO120A 3BSE018293R1 Analog Output Board

ABB CI855K01 3BSE018106R1 Interface Module

HONEYWELL 05701-A-0301 Single Channel Control Card

HIMA F6215 Analog input module

3005319639

3005319639