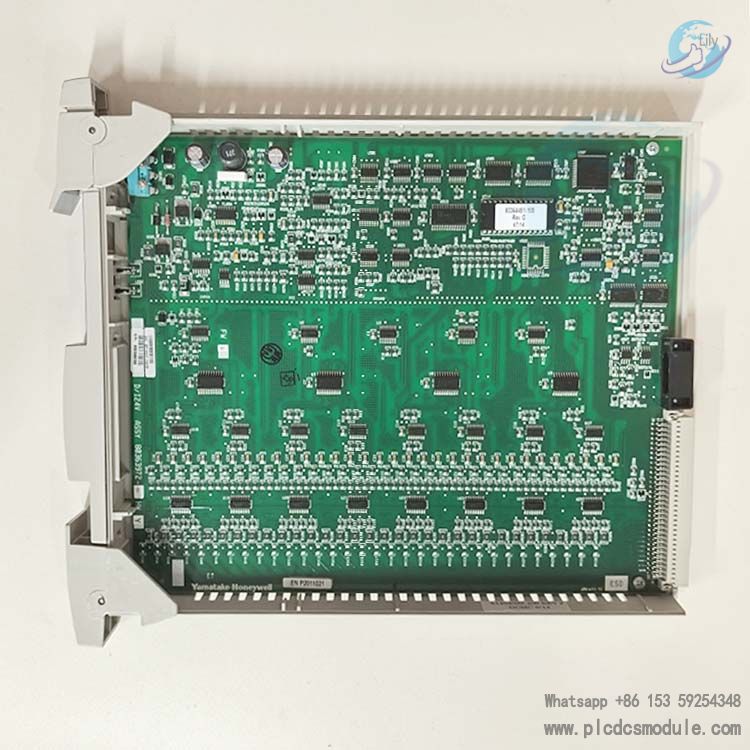

As a key device in the field of industrial safety monitoring, this control card is widely used in scenarios requiring real-time monitoring of combustible or toxic gas concentrations—such as petrochemicals, metallurgy, energy, and warehousing—thanks to its high compatibility, stable signal processing capability, and flexible configuration features. It provides reliable technical support for industrial environmental safety.Its design complies with international industrial safety standards. It can not only accurately interface with various gas sensors that output 4-20mA signals but also enable convenient calibration, maintenance, and system configuration through the supporting Engineering Card, helping enterprises build an efficient and stable gas safety monitoring system.

I. Core Functions and Technical Features

1. Accurate Signal Processing and Data Display

Signal Input and Processing

Specifically designed for 4-20mA standard current signals, it can accurately receive gas concentration signals from 4-20mA loop-powered sensors or transmitters. The built-in microprocessor performs filtering, amplification, and linearization on the signals to ensure data accuracy. It supports real-time monitoring of sensor signals and can display the sensor loop current (unit: mA), intuitively reflecting changes in gas concentration.

Four-Part LCD Display System

2. Multi-Level Alarm Management and Safety Assurance

Support for Multiple Alarm Types

It can be configured with three levels of concentration alarms: A1 (first-level alarm), A2 (second-level alarm), and A3 (third-level alarm). It also supports STEL (Short-Term Exposure Limit, usually a 10/15/30-minute time-weighted average), LTEL (Long-Term Exposure Limit, usually an 8-hour time-weighted average), and Rate (rate-of-rise alarm, predicting gas concentration upward trends) to meet safety threshold requirements of different industrial scenarios.

Alarm Indication and Linkage

Equipped with 3 red alarm LEDs (A1/A2/A3), 1 yellow fault LED (FAULT), and 1 yellow inhibit LED (INHIBIT), the alarm status is intuitively visible. It supports linkage with external relay cards (such as Double SPCO, Triple SPCO, High Integrity Relay Card) — when the concentration exceeds the limit, it triggers relay output to drive external emergency devices like audible-visual alarms and exhaust equipment, forming a complete safety response chain.

Fault and Inhibit Protection

Built-in hardware and software self-detection functions. When the sensor is disconnected, short-circuited, or the signal exceeds the preset range, the FAULT LED lights up and triggers a fault alarm. It supports local or remote inhibit functions (INHIBIT) to temporarily block alarm output during system startup (approximately 30-second warm-up period), calibration, or maintenance, avoiding false triggers.

3. Flexible Configuration and Convenient Operation

Reset/Select One-Button Dual Function

Compatibility Expansion

Supports external connection of the 05701-A-0285 analog output module (optional), which can provide 0-20mA or 4-20mA isolated current loop output. It is used to connect external devices such as chart recorders and PLCs (Programmable Logic Controllers) to achieve secondary data storage or remote monitoring.

Engineering Card Linkage Configuration

Through the Honeywell Engineering Card (Part Number: 05701-A-0361), operations such as zero calibration (ZERO), span calibration (SPAN), alarm threshold adjustment, and system clock setting can be performed on the control card. It also supports connection to a computer via an RS232 interface, using engineering software for complex parameter configuration (such as alarm types, relay action modes).

二、Hardware Specifications and Environmental Adaptability

1. Hardware Parameters

| Item | Specification Details |

|---|---|

| Supply Voltage | 18V-32V DC (via system DC input card or independent power supply; an external 1A fuse is required for independent power supply) |

| Typical Power Consumption | 3.25W (including power supply for sensor circuit) |

| Signal Input Range | 0-25mA (linear processing, compatible with 4-20mA standard signal) |

| Maximum Line Resistance | 500Ω (total loop resistance including sensor) |

| Display Linearity | ±1% fsd (full scale deflection) |

| Display Repeatability | ±1% fsd (full scale deflection) |

| Remote Input (Inhibit/Reset) | Activation voltage >2V, maximum input voltage 32V, maximum input current 5mA |

| Dimensions (Height × Width × Depth) | 112mm×25mm×170mm |

| Weight | 165g |

| Terminal Compatibility | Supports 2.5mm² (14 AWG) solid or stranded wires |

2. Environmental Adaptability

Application Scenarios and Selection Recommendations

1. Application Scenarios

2. Selection Considerations

Customers who purchased this product are also browsing the following products:

ABB GVC704AE01 3BHB003023P201 IGCT Module

Bently Nevada 9200/06-01-10-00 Vibration sensor

GE Multilin 369-LO-0-M-F-E-0-0 Motor Management Relay

GE 531X303MCPBBG1 F31X303MCPAPG100600 Power Control Board

3005319639

3005319639