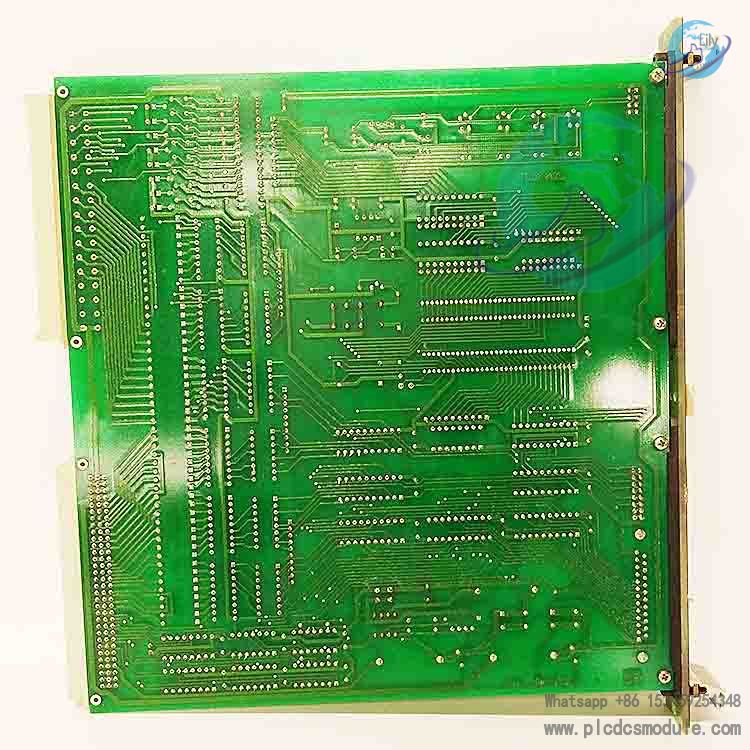

The SES 2422 OUT2422 Daico Printed Circuit Board (PCB) is a professional industrial automation component specifically engineered for signal processing, control execution, and data communication in harsh industrial environments. As a core component of modern Distributed Control Systems (DCS) and industrial control devices, it integrates output-oriented functionalities (indicated by the "OUT" in its name) with a rugged hardware design, making it suitable for industries such as manufacturing, energy, transportation, and process control.

Technical Specifications

1. Electrical Performance

Power Supply Requirements

Input Voltage: Adopts the industrial automation module standard of 24V Direct Current (DC) with a ±10% tolerance range (21.6V - 26.4V), enabling adaptation to power grid fluctuations.

Output Current: The standard model provides 0.5 Ampere (A) per channel, while the high-power model can achieve a total output current of up to 2A, allowing direct driving of devices such as motors, valves, or actuators.

Power Consumption: Delivers excellent power efficiency, with a power consumption of <10 Watts (W) under no-load conditions and <30W at full load. This effectively reduces heat generation — excessive heat will accelerate the aging of solder joints and capacitors, which is crucial for the service life of the Printed Circuit Board (PCB).

Signal and Control Capabilities

Digital Output Channels: The standard configuration includes 8 digital output channels, supporting on/off control of 24V DC loads (e.g., relays, solenoid valves).

Signal Type: Utilizes discrete digital signals (on/off). Some variants support Pulse-Width Modulation (PWM) functionality, enabling variable-speed control (such as adjusting motor speed).

Analog Conversion: Integrates an 8-bit/16-bit Digital-to-Analog Converter (DAC), which can convert internal digital control signals into analog outputs to match analog actuators like proportional valves.

Signal Response Time: The signal response time is <1 millisecond (ms) (referring to signal propagation delay), ensuring real-time control in time-sensitive applications such as assembly line synchronization.

2. Communication Interfaces

One of the core advantages of the SES 2422 OUT2422 lies in its flexible connectivity, which is specifically designed for seamless integration with Distributed Control Systems (DCS) and Programmable Logic Controllers (PLC).

Main Communication Protocols

PROFINET (Industrial Ethernet Protocol): Features a transmission rate of 10/100 Megabits per second (Mbps), enabling high-speed data exchange with controllers from Siemens, Phoenix Contact, or Rockwell Automation.

RS485 (Serial Communication Protocol): Boasts a maximum transmission rate of 115.2 Kilobits per second (Kbps) and supports the Modbus RTU protocol. It can achieve long-distance connections of up to 1200 meters, making it suitable for remote Input/Output (I/O) or Human-Machine Interfaces (HMI).

Interface Ports

Equipped with an Ethernet port (RJ45) and a terminal block (for RS485). Some models also come with fiber optic ports, enabling Electromagnetic Interference (EMI)-free communication in high-EMI environments such as near motors.

Additionally, the module can transmit real-time status data (e.g., channel faults, power supply voltage) via the communication interface, supporting remote troubleshooting without the need for on-site contact with the device.

Application Scenarios

The SES 2422 OUT2422 Daico Printed Circuit Board (PCB) is specifically designed for application scenarios that require reliable digital output control and seamless communication, mainly including the following:

1. Manufacturing and Assembly Lines

2. Energy and Power Generation

3. Transportation and Logistics

4. Process Control (Chemical Industry, Food and Beverage Industry)

Customers who purchased this product are also browsing the following products:

ABB UCD224A102 3BHE023681R0102 controller Module

Bently Nevada 9200/06-01-10-00 Vibration sensor

GE DS6800CCIE1F1D Power Distribution Module

GE Multilin UR6AV DIGITAL I/O MODULE

3005319639

3005319639