Targeted at industrial automation scenarios, this product can realize real-time monitoring of control devices such as PLCs, issuance of operation instructions, and management of alarm information. Meanwhile, it supports the hot IP switching function and is compatible with high-availability redundant PLC systems.

related documents

Technical Specifications

Display and Touch Parameters

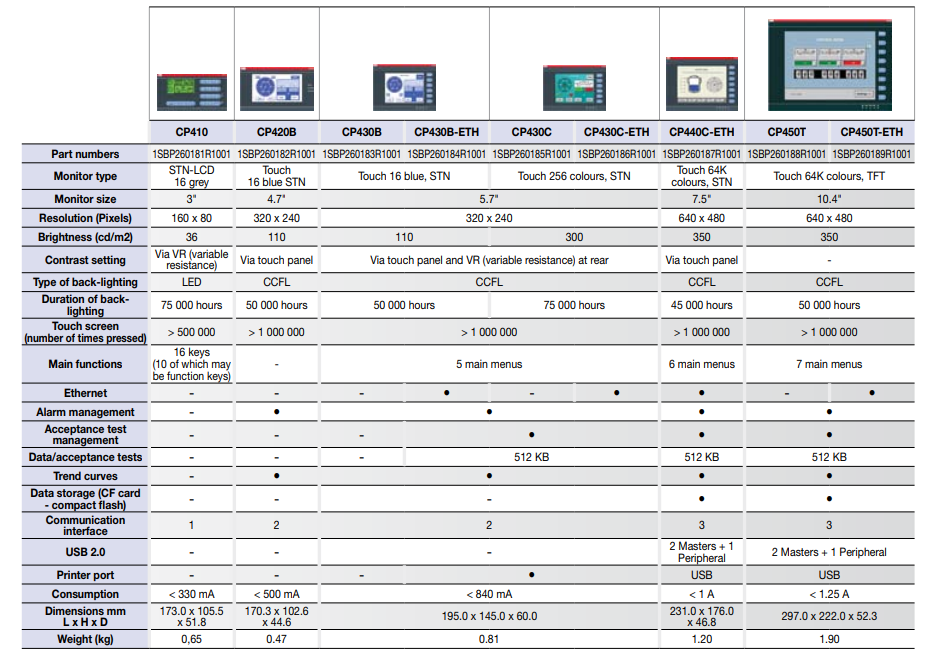

Screen Specifications: 10.4-inch TFT true-color display supporting 64K color display, with a resolution of 640×480 pixels. It adopts CCFL (Cold Cathode Fluorescent Lamp) backlighting with a backlight lifespan of up to 50,000 hours. The touch method is an analog resistive touch screen with a touch lifespan of over 1 million times, which can meet the high-frequency operation needs of industrial scenarios.

Operation Keys: Equipped with 7 function keys plus 1 menu key, which can assist in completing shortcut operations and menu switching, adapting to the complex operating environment of industrial sites.

Hardware Performance Parameters

Processor: Built-in 32-bit RISC processor with 8MB user memory, supporting graphics and text display, as well as macro instruction and ladder diagram logic operations, enabling simple local logic control and data processing.

Communication Interfaces: Standard Ethernet interface, along with RS232 and RS485 interfaces (Modbus as the standard communication protocol). It is also equipped with 2 USB host interfaces plus 1 USB device interface, and supports CF memory card expansion, realizing program download, data storage, and multi-device interconnection.

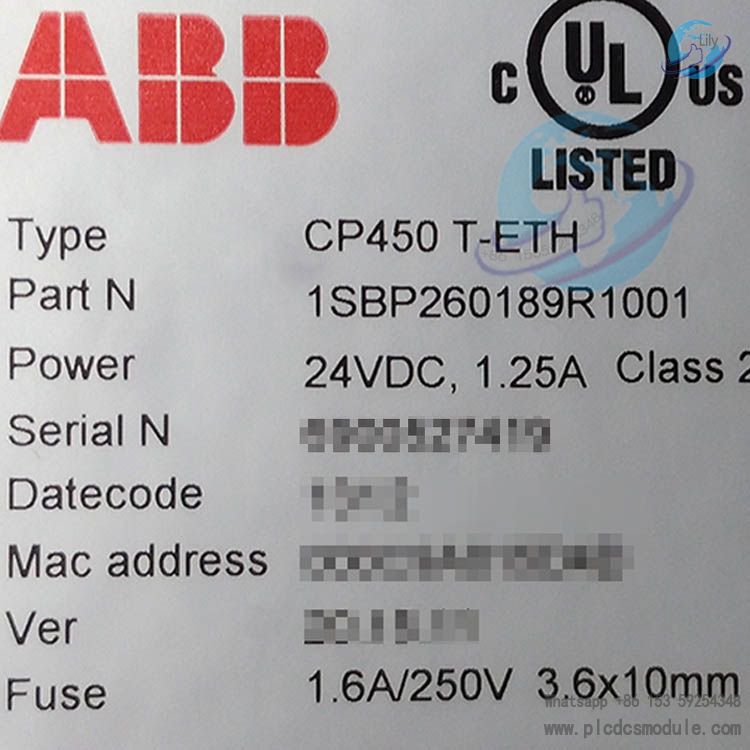

Power Supply and Power Consumption: Powered by 24V DC with an allowable voltage fluctuation range of ±15% and a working current not exceeding 1.25A, adapting to the DC power supply system of industrial sites.

Structure and Protection Parameters

Protection Level: The front protection level is IP65, which can resist dust and low-pressure water jets; the back protection level is IP20, which needs to be installed in a control cabinet.

Dimensions and Installation Size: The product weighs approximately 1.9kg, with panel dimensions of 297mm×222mm×52mm. The opening size needs to match the standard installation position of the industrial control cabinet, supporting embedded installation.

Environmental Adaptability: The operating temperature range is 0℃~50℃, the storage temperature range is -20℃~70℃, and the relative humidity is 5%~85% (non-condensing), which can meet the temperature and humidity requirements of most industrial production environments.

Functional Features

Human-Machine Interaction Functions

It supports multiple display forms such as graphics, text, and animations, and allows customization of production monitoring interfaces. Meanwhile, it is equipped with recipe management, alarm and event management functions, which can record abnormal information during the production process in real time and trigger prompts.A built-in real-time clock enables time-stamped data recording and event tracing. It also supports online and offline simulation, facilitating engineering debugging and program verification.

Communication and Redundancy Functions

The Ethernet interface supports the hot IP switching function. When the main communication link is interrupted, it can automatically or manually switch to the standby PLC communication channel without restarting the device, ensuring the continuous operation of the system. This feature is especially suitable for high-availability industrial control systems.It is compatible with mainstream industrial communication protocols such as Modbus, and can seamlessly connect with PLCs like ABB AC500/AC500-eCo. Additionally, it supports multi-driver communication (up to 2 communication drivers can be connected), meeting the networking needs of multiple devices.

Safety and Compatibility

It has a password protection function that allows hierarchical setting of operation permissions, preventing unauthorized personnel from modifying control parameters and ensuring the security of the production system.It complies with ROHS environmental certification and UL safety certification, and follows industrial-grade design standards, enabling it to adapt to harsh industrial electromagnetic environments and power supply conditions.

Applicable Scenarios and Supporting Resources

Typical Application Scenarios

It is widely used in production line monitoring and equipment operation and maintenance management in industries such as machinery manufacturing, water treatment, photovoltaic power generation, and wind power generation. It is especially suitable for redundant PLC control systems with high system availability requirements, enabling production data visualization, remote operation, and fault early warning.

Supporting Programming and Communication Resources

It needs to be paired with the dedicated CP400Soft programming software (order code: 1SBS260284R1001) for interface development. A TK405 communication cable (SubD9 interface) can be used to achieve local connection with AC500 PLCs, while the Ethernet interface supports remote program download and data interaction.

Customers who purchased this product are also browsing the following products:

ABB CI627A 3BSE017457R1 Communication Interface

ABB UAD154A 3BHE026866R0101 PCB board

EMERSON 5X00226G04 I/O INTERFACE MODULE

GREENSPRING 320-1026C control system module

3005319639

3005319639