This device integrates signal acquisition, processing, output and communication functions, and supports the connection of multiple types of load cells. It has a comprehensive debugging, operation and maintenance, and fault diagnosis system, which can adapt to web tension monitoring scenarios of different complexity in industrial production. Meanwhile, it meets a number of international safety and electromagnetic compatibility certification standards including CE, UL, and CSA. It is suitable for tension closed-loop control or condition monitoring in web processing industries such as papermaking, printing, textiles, and film processing.

The PFEA113 Tension Measurement System is mainly composed of the PFEA113 tension electronic unit, the PFCL 301E/PFTL 301E/PFRL 101/PFTL 101/PFCL 201/PFTL 201 series of load cells, and the PFXC 141 junction box.

related documents

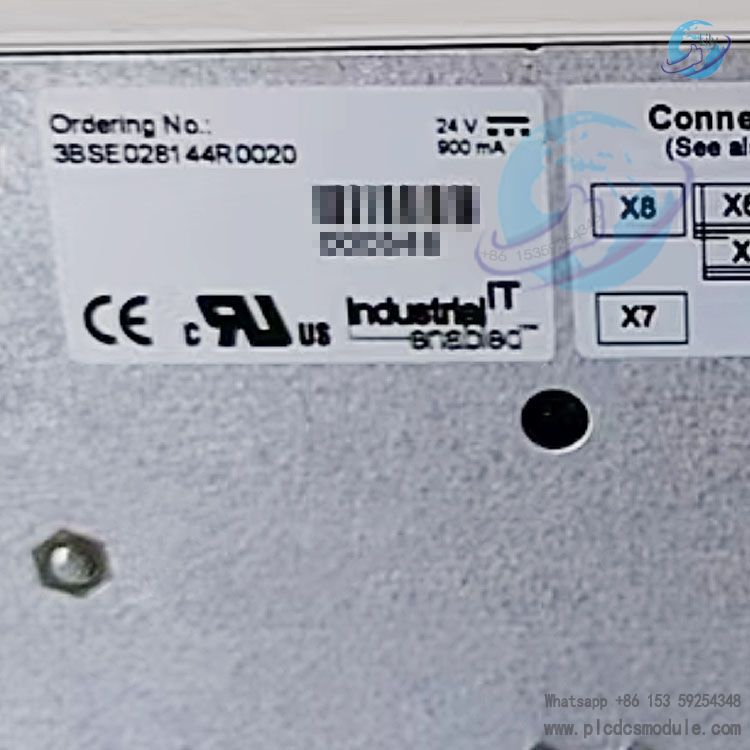

![]() PFEA113-20 3BSE028144R0020.pdf

PFEA113-20 3BSE028144R0020.pdf

Technical Parameters

1. Power Supply Parameters

Different device versions correspond to different power supply specifications. The IP20 (unsealed DIN rail version) adopts DC power supply with an operating voltage range of 18-36V DC (nominal 24V DC), is equipped with a built-in auto-reset fuse, and has a power consumption of 15W (excluding digital outputs). The IP65 (NEMA 4 wall-mounted version) supports dual AC/DC power supply: the AC supply voltage range is 85-264V AC (100V-15% to 240V+10%) with a frequency of 47-63Hz, and the DC supply voltage range is 18-36V DC (nominal 24V DC); it is equipped with an external slow-blow fuse (2A/250V), and the current is 0.1-0.2A when powered by AC.

2. Sensor Excitation Parameters

The excitation current is 0.5A rms at 330Hz (stable constant current output). The maximum load capacity can drive 4 compatible Pressductor sensors (such as PFCL 301E, PFTL 301E and other models), and allows a maximum cable resistance of 10Ω and capacitance of 1μF between the sensor and the device.

3. Input and Output Parameters

It covers multiple aspects of functions:

4. Communication Parameters

The communication interface is a Profibus DP slave station (RS485 physical layer), supporting a maximum transmission rate of 12Mbit/s, with an address range of 0-125 configurable via the local menu. Data interaction supports transmission of 6 tension measurement values, issuance of commands such as zero setting/gain scheduling, and reporting of device fault status.

5. Environmental and Mechanical Parameters

The specific indicators are as follows:

Functions and Features

1. Measurement Principle

Based on ABB patented Pressductor electromagnetic induction technology, two orthogonal coils inside the sensor change their magnetic field coupling state when subjected to force, generating electrical signals proportional to tension without mechanical deformation. It features overload resistance, vibration resistance, and strong long-term stability, and the measurement accuracy is not affected by mechanical wear of the sensor.

2. Tension Measurement Modes for Multi-Scenario Adaptation

3. Flexible Debugging and Configuration

4. Comprehensive Fault Diagnosis

The device can real-time monitor faults such as flash memory/EEPROM failure, power supply abnormality, sensor excitation failure, Profibus communication failure, and synchronization failure. Fault status is reported via local indicators, display screen, and Profibus. Meanwhile, it supports switching to single-side measurement mode when a single sensor fails, ensuring production continuity.

5. Data Recording and Simulation Functions

Applications and System Composition

A complete PFEA113-20 tension system typically consists of the following components: the PFEA113-20 electronic unit, Pressductor load cells (such as PFCL 201, PFTL 301E, etc.), a junction box (PFXC 141, optional), as well as a matching insulation amplifier (PXUB 201) or relay board (PXKB 201, optional). Its typical applications include:

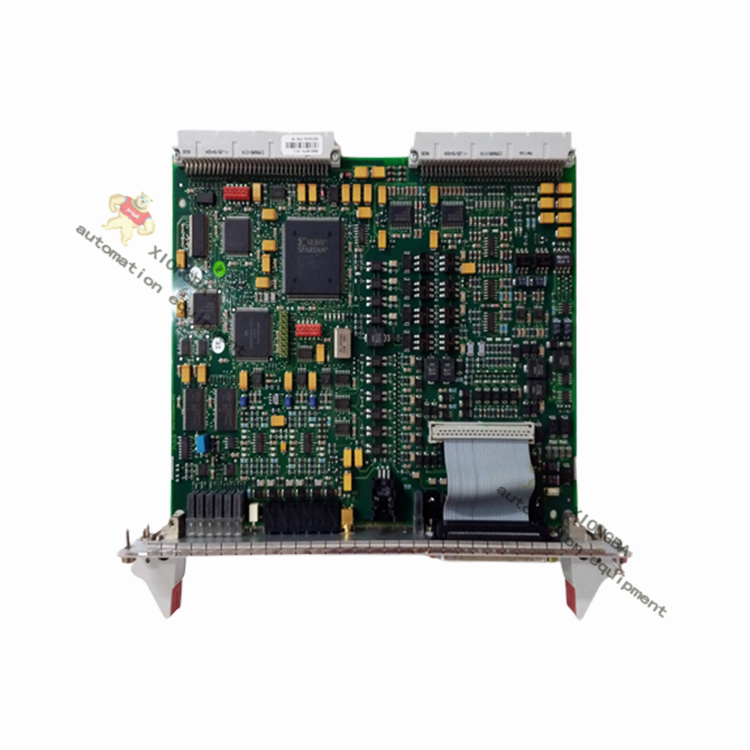

Customers who purchased this product are also browsing the following products:

ABB PVD164A2059 3BHE014340R2059 processor module

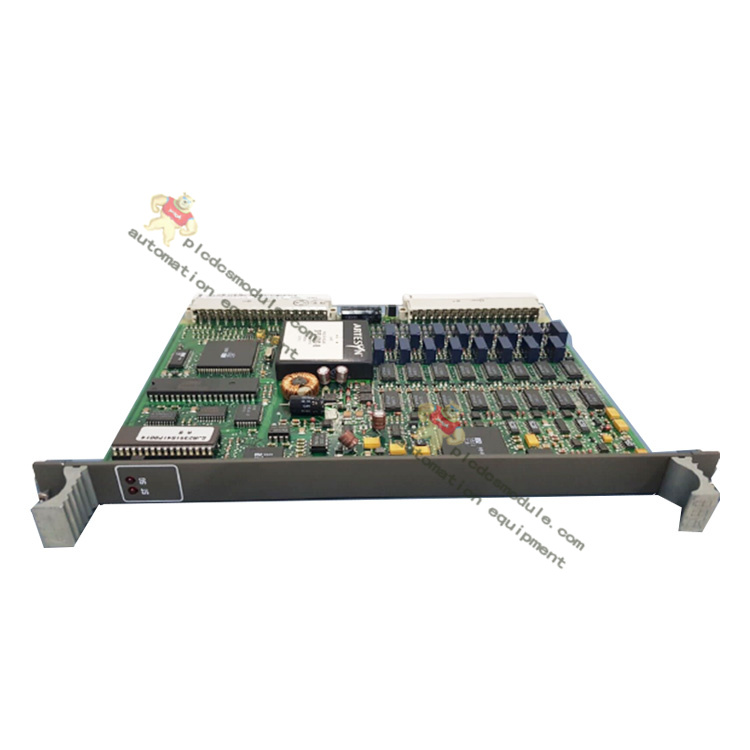

GE DS200KLDBG1ABC DS215KLDBG1AZZ03A PCB board

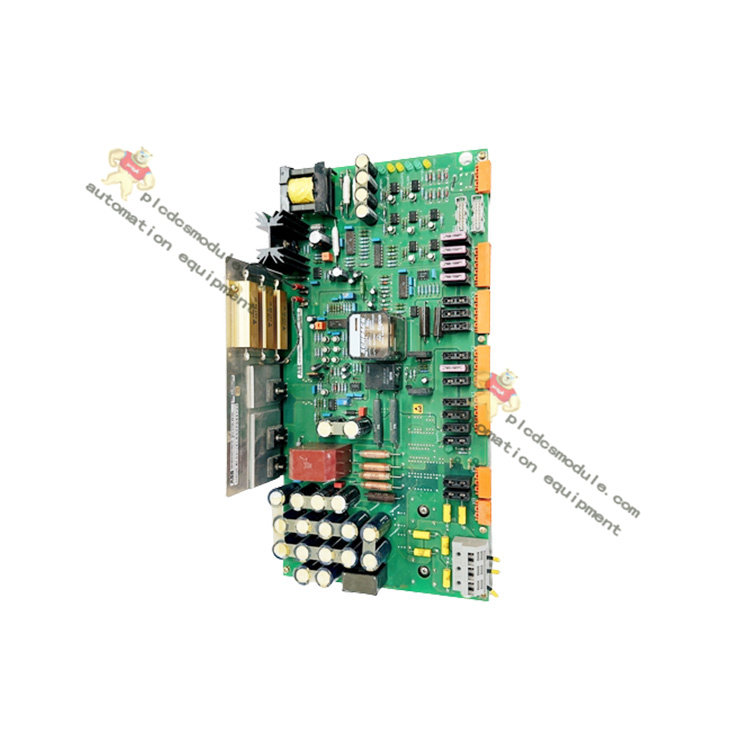

ABB S-073H 3BHB030477R0007 PHASE MODULE

PROSOFT PTQ-PDPMV1 Interface Module

3005319639

3005319639