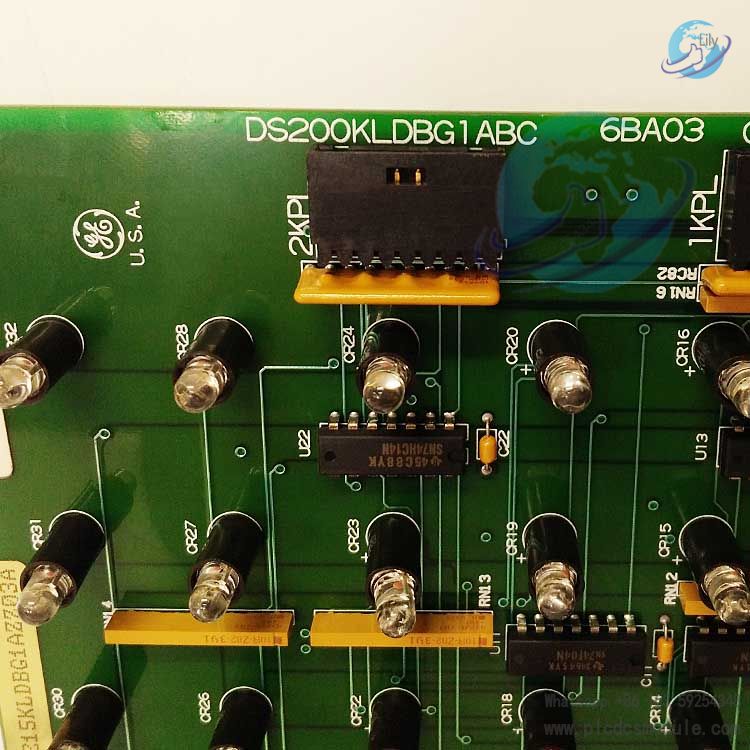

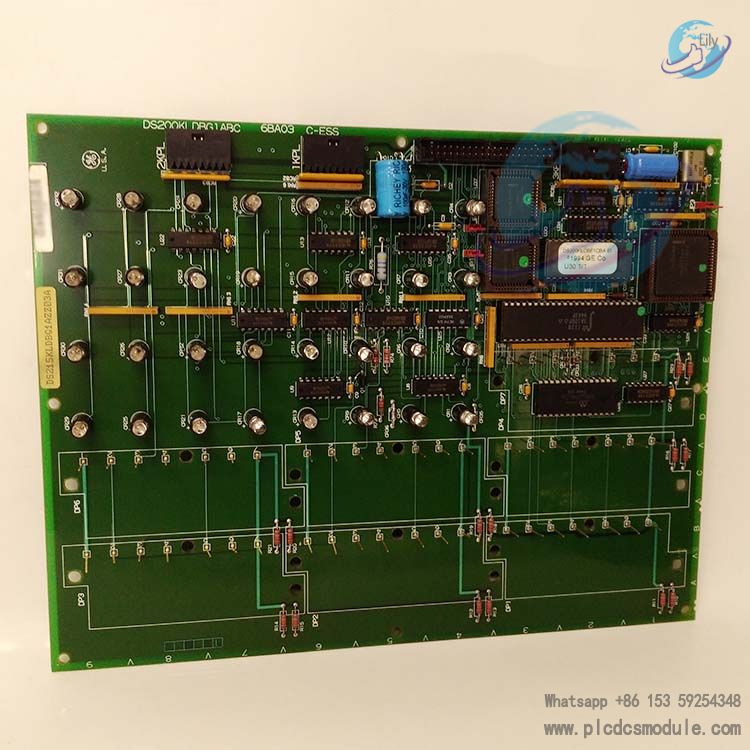

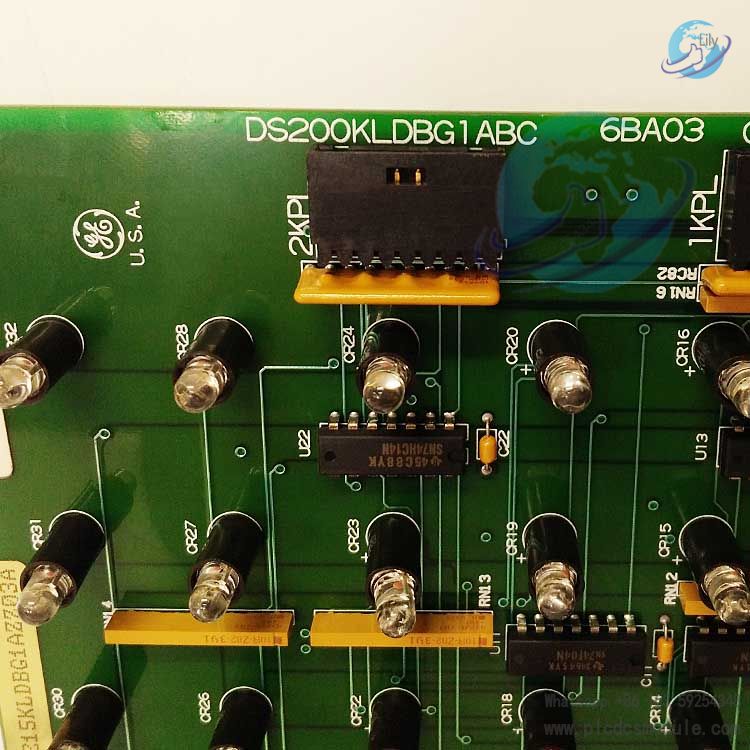

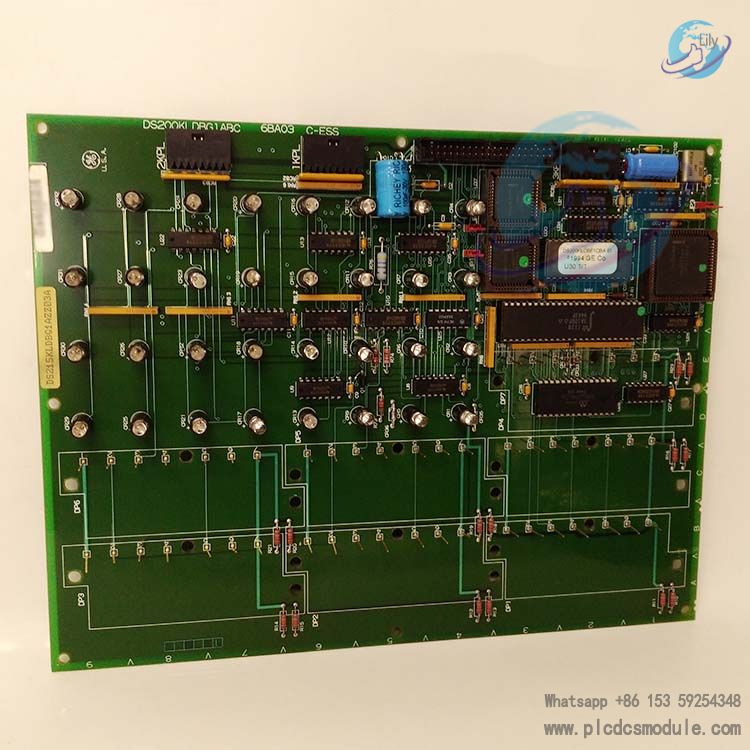

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. DS200KLDBG1ABC/DS215KLDBG1AZZ03A is a core printed circuit board developed by General Electric for the Speedtronic Mark V gas turbine control system. Often regarded as an I/O-related function board,DS200KLDBG1ABC/DS215KLDBG1AZZ03A undertakes critical tasks such as signal processing, data transmission, and equipment control. With its high integration and anti-interference design, it is suitable for industrial scenarios like gas turbines in the power, petroleum, and chemical industries where stringent operational stability requirements are imposed. It can work collaboratively with other boards in the Mark V series to ensure the accurate and efficient operation of the entire control system, serving as an important spare part in the field of industrial automation control.

Technical Specifications

Power-related ParametersThe rated power covers 5 kW, 10 kW, and 22 kW (under 460V operating conditions). The internal shunt resistor has a continuous rated power of 200W and a peak rated power of up to 40,000W. Notably, the 22 kW system module requires an additional external shunt resistor for proper operation.

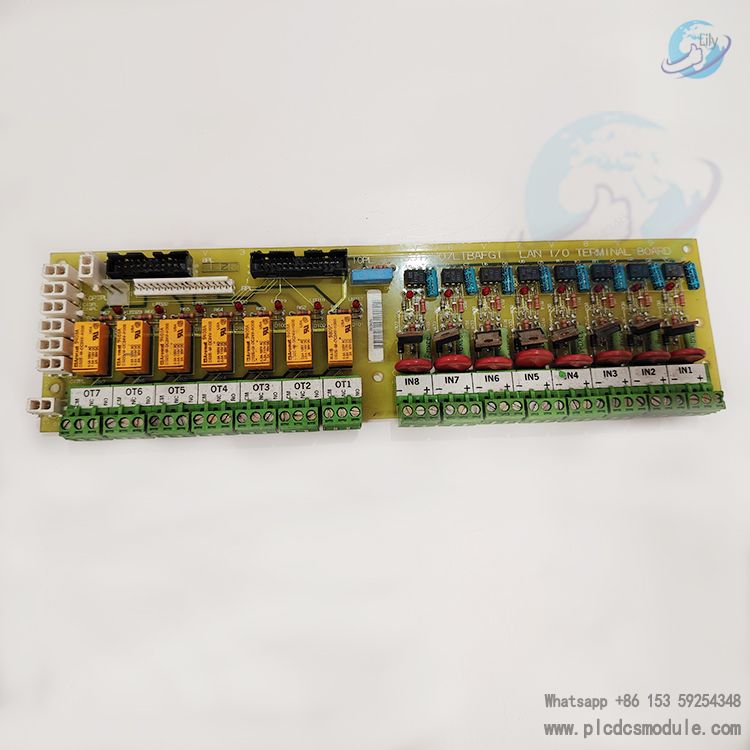

Electrical ParametersIt adopts a three-phase power supply design and the input power frequency is compatible with 50/60Hz, enabling the matching of 530-680V DC link voltage with the input voltage. It supports a variety of signal types commonly used in industrial settings, including LVDT inputs, servo valve outputs, and 4-20mA input/output signals.

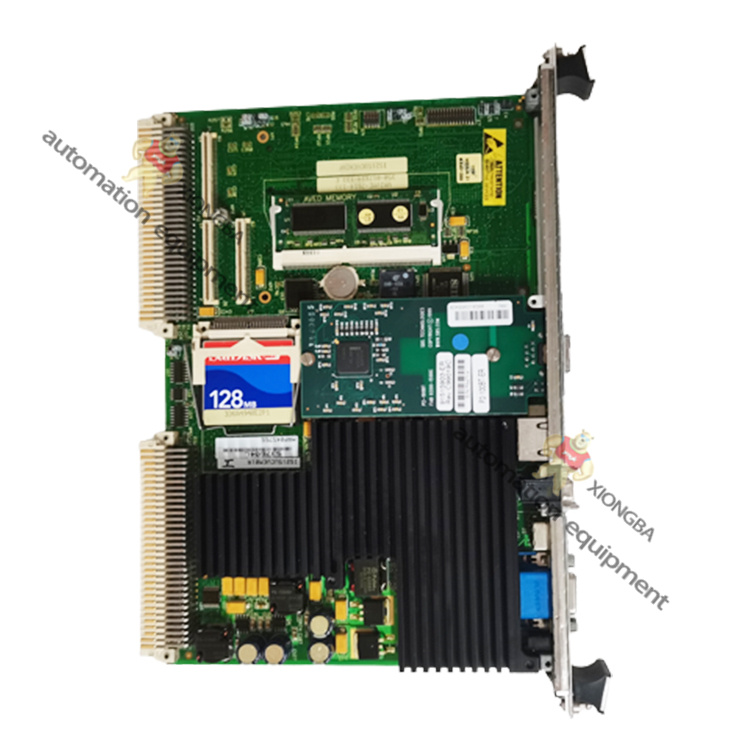

Communication PerformanceIt is compatible with multiple communication protocols such as RS485, Modbus RTU, and CAN, allowing for data interaction with upper-level systems and other devices, thus ensuring the stable transmission of control commands and equipment status data.

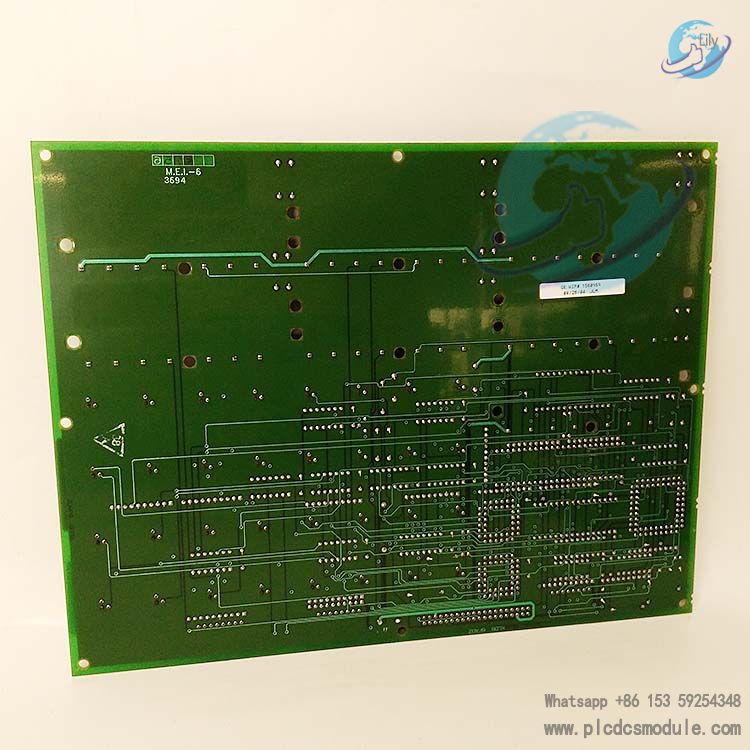

Physical SpecificationsIt weighs approximately 1.07 pounds, with factory-reserved drill holes at the corners and the middle of the side edges of the board for easy installation and fixation. In addition, the supplier indicates that similar-specification products have dimensions of approximately 20×25×30 cm and a weight of 2.5KG, with the actual parameters subject to specific installation scenarios.

Environmental AdaptabilityIt complies with industrial-grade environmental standards and can adapt to operating conditions with high temperature, high humidity, and strong electromagnetic interference. The reference operating temperature of some products in the same series is 0°C - 60°C, which can meet the environmental requirements of most industrial sites.

Functional Features

Excellent Signal Processing Capability

The DS215KLDBG1AZZ03A board excels in signal processing, capable of scaling and conditioning various analog signals read from the terminal board. Key industrial signals it handles include compressor stall detection signals and fuel flow pressure signals. By reducing signal distortion and ensuring the accuracy of signal transmission, it provides reliable data support for critical equipment control decisions in industrial settings.

High Reliability and Stability

Built with high-quality industrial-grade components and advanced control technologies, this board boasts a 150% overload capacity for 1 minute, effectively coping with load fluctuations common in industrial sites. Additionally, it is equipped with a contact input noise reduction circuit that achieves surge protection, preventing external interference from affecting the stable operation of the equipment and ensuring continuous performance in harsh industrial environments.

Good Adaptability and Convenient Maintenance

As a dedicated board for the Speedtronic Mark V series, it perfectly matches other boards in the series' control system, such as STCA and TCQA. It realizes signal interaction with the core bus and other boards through connectors like 3PL. Its modular structural design not only simplifies the installation process but also enables targeted maintenance or direct replacement in case of failure, significantly reducing maintenance difficulty and minimizing downtime costs for industrial operations.

Application Scenarios

Core Application: Power Industry Gas Turbine Control

As a core printed circuit board (PCB) for the GE Mark V gas turbine control system, the DS215KLDBG1AZZ03A plays a pivotal role in gas turbine control systems of power plants and substations. It undertakes the critical task of ensuring the stable operation of generating units. Leveraging its robust signal processing capabilities and strong anti-interference performance, the DS215KLDBG1AZZ03A maintains the accuracy of control commands and operational data transmission, laying a solid foundation for the safe, continuous, and efficient power supply of power facilities.

Extended Applications Across Multiple Industrial Sectors

Beyond the power industry, the DS215KLDBG1AZZ03A PCB is widely applicable to various industrial scenarios that require high-precision automation control, thanks to its excellent compatibility and reliability. Key extended application scenarios include:

Petrochemical Industry

In refineries, chemical plants, and other petrochemical facilities, the DS215KLDBG1AZZ03A is applied to the control of core power equipment such as gas turbines and compressors. It ensures the stable operation of production systems by accurately processing equipment operation signals and transmitting control instructions, effectively reducing the risk of unplanned downtime and improving the overall operational efficiency of petrochemical production lines.

Food Processing Industry

Within automated food processing production lines, the DS215KLDBG1AZZ03A supports precise regulation of key production processes. It realizes accurate control over material conveying, temperature adjustment, pressure monitoring, and other links through high-precision signal management. This not only helps food processing lines achieve full automation and high-efficiency operation but also enhances the consistency and stability of product quality, meeting the strict quality control requirements of the food processing industry.

Customers who purchased this product are also browsing the following products:

GE DS215SLCCG1AZZ01A Mark V LAN Communications Card

Emerson 1C31197G05 PMOD ASSY MODULE

TRICONEX 3101S2 Triple Redundant Processor Module

ABB LDGRB-01 3BSE013177R1 interface module

3005319639

3005319639