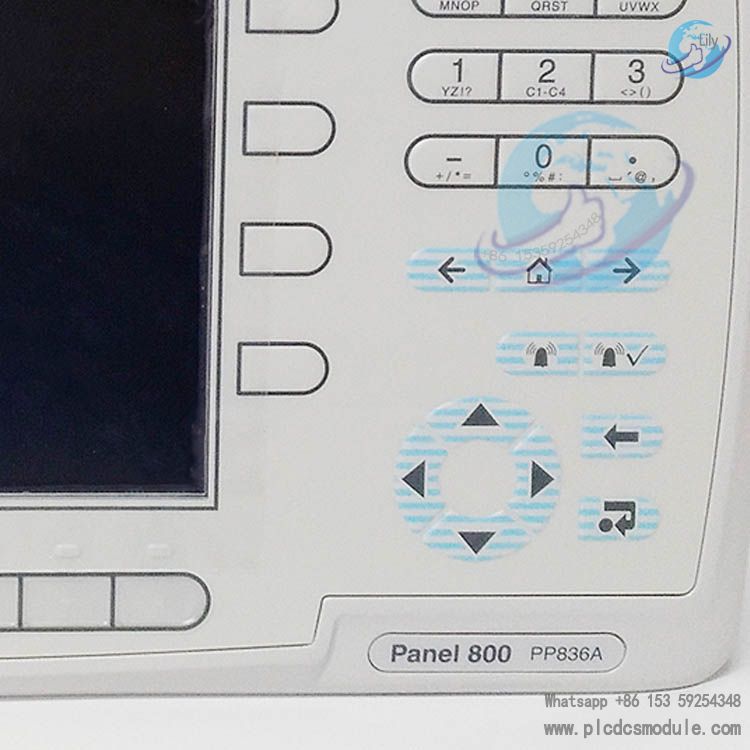

The ABB PP836A 3BSE042237R2 is an industrial-grade operator panel belonging to the Panel 800 series (Version 5.1/3), which is mainly used for human-machine interaction in industrial scenarios. It can realize core functions such as text display and control, dynamic indication, time channel management, alarm handling, and recipe management.

This panel adopts object-oriented operation logic. It is necessary to complete project configuration through the Panel Builder 800 configuration tool on the PC side, and then transmit and store the configured project in the panel. It is compatible with various automation control devices such as PLCs and servo drives, and is widely used in the field of industrial automation control. Moreover, it complies with the relevant requirements of the EMC Directive 89/336/EEC and the Low Voltage Directive 72/23/EEC.

related documents

Safety Protection Specifications

Hazardous environment compatibility: Suitable for Class I, Division 2, Groups A/B/C/D hazardous areas or non-hazardous areas; in Canada, it complies with corresponding explosion-proof warning requirements. The maximum ambient temperature is 40℃ for horizontal installation and 50℃ for vertical installation. It is strictly prohibited to disassemble the device, replace expansion units, or change batteries without powering off or in non-safe areas.

Installation and usage prohibitions: Installation and operation must be completed by professional personnel. The installation environment must be free of high explosion risks, strong magnetic fields, direct sunlight, and severe temperature changes. Do not use sharp objects or excessive force to operate keys and displays, and safety functions such as emergency stop cannot be controlled by this panel. The power supply must be disconnected before maintenance, and only the battery model recommended by the supplier should be used to prevent explosion risks.

Technical Specifications

Form Factor and Installation

The front panel dimensions are 285×177×6mm, with an installation depth of 56mm (156mm including clearance). The thickness of the mounting plate shall meet the range of 1.5–9.0mm, and the cutout size is 245.5×138.5mm. The front panel has an IP66 protection rating, while the rear part has an IP20 protection rating.

Material and Service Life

The front panel keyboard is a membrane switch with metal domes, and its surface is covered with Autotex F157 reverse-printed film, which can withstand 1 million operations. The back of the panel is made of powder-coated aluminum alloy, and the total weight of the whole device is 1.4kg.

Display Specifications

It adopts a TFT-LCD display with a resolution of 640×480 pixels and support for 64K colors. It is equipped with an LED backlight, whose service life exceeds 25,000 hours at 25℃, and the effective display area is 131.5×98.6mm.

Communication Interfaces

It is equipped with RS422/RS485 (25-pin D-sub female connector), RS232C (9-pin D-sub male connector), shielded RJ45 Ethernet port, USB1.1 host Type-A interface (maximum output current of 500mA) and device Type-B interface, as well as a Type I/II CF card slot.

Storage Configuration

The application program flash memory is 12MB (including fonts), and the built-in CF card can be expanded (supports industrial-grade CF cards such as SiliconSystems SiliconDrive, and the card capacity needs to be configured in Panel Builder 800).

Power Supply and Power Consumption

The power supply is 20–30V DC (nominal 24V DC), with a normal power consumption current of 0.4A and a maximum of 0.9A. It has a built-in 3.15AT/5×20mm DC fuse. The PP836A is equipped with a rechargeable real-time clock battery, while the PP836 uses a CR2450 battery (with a service life of ≥3 years).

Environmental Adaptability

The operating temperature ranges from 0–50℃ for vertical installation and 0–40℃ for horizontal installation. The storage temperature is -20–70℃, and the relative humidity is 5%–85% (non-condensing).

Installation and Expansion Capabilities

Basic Installation Process

First, unpack and inspect the panel to ensure there is no transportation damage, then process the installation position according to the cutout size, and fix the panel with 6 fasteners at a torque of 0.5–1.0Nm. For wiring, ensure that the panel and the controller have the same grounding potential; grounding should use M5 screws and short grounding wires with a cross-sectional area of ≥2.5mm², and communication cables must be shielded and separated from high-voltage cables.

Mode Switch Functions

Four DIP switches on the back can switch the working mode. For example, 0000 is the normal operation mode, 0010 is the system recovery mode (restoring factory settings), and 1000 is the service menu mode (where IP can be set, projects can be erased, and the touch screen can be calibrated). To switch modes, the power must be turned off first and then restarted.

Expansion Module Support

It can be externally connected to a Profibus DP expansion module (dimensions: 87×70×30mm, weight: 0.1kg). During installation, the power supply must be disconnected, the plastic cover of the expansion port removed, and then the module fixed with M3×6 screws. In addition, the CB810 USB-to-Ethernet adapter can be used to realize project transmission between the PC and the panel (for transmission only, not for fixed installation).

Chemical Resistance

Metal Housing

The powder-coated aluminum alloy housing can withstand 43% phosphoric acid, but has limited resistance to chemicals such as 3% nitric acid and 10% sodium hypochlorite. It must not come into contact with highly corrosive chemicals including concentrated acetic acid, acetone, and 30% nitric acid.

Touch Screen and Coating

The Autotex F157/F207 coating can resist most daily and industrial chemicals (e.g., ethanol, 30% potassium hydroxide, 10% sulfuric acid) for more than 24 hours, but is not resistant to concentrated mineral acids, dichloromethane, and similar substances. The touch screen surface can tolerate exposure to acetone and isopropanol for 10 minutes, and toluene for 5 hours. It is recommended to install an Autoflex EB protective film, and polyester-based coatings should not be exposed to long-term outdoor sunlight.

Customers who purchased this product are also browsing the following products:

ABB PFEA113-20 3BSE028144R0020 Tension Electronics

Emerson 1C31233G01 SINGLE END MODULE

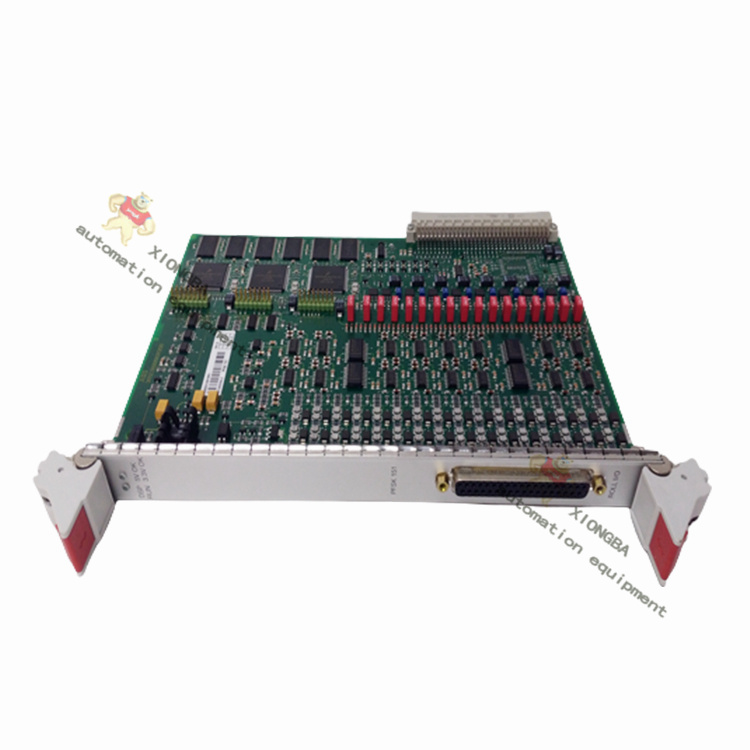

ABB PDD205A1121 3BHE025335R1121 circuit board

ALSTOM ICP232 029.359325 control module

3005319639

3005319639