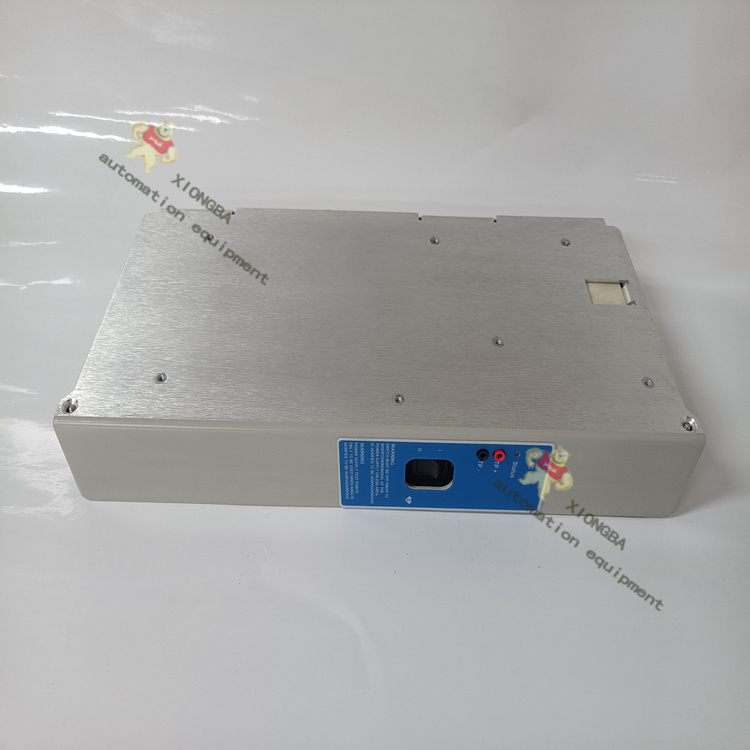

The Honeywell TC-CCR014 is a redundant ControlNet Interface Module (CNI), specifically designed for the Experion control system. Its core function is to establish redundant communication connections between the controller and the ControlNet network. Supporting both Supervisory ControlNet and I/O ControlNet network architectures, it is suitable for industrial control scenarios with high requirements for communication reliability.

With a redundant design that eliminates single points of failure, this module ensures continuous and stable data transmission between the controller and devices such as servers and remote I/O chassis. It serves as a critical component for ensuring network communication redundancy in industrial process control.

related documents

Core Functions & Positioning

Redundant Communication Support: As a dedicated module for redundant ControlNet cable configurations, it provides dual communication paths. When one network path fails, it automatically switches to the standby path to prevent communication interruption.

Cross-Network Compatibility: It can be deployed in both Supervisory ControlNet networks (connecting servers and controllers) and I/O ControlNet networks (connecting controllers and remote I/O devices), meeting the requirements of control networks at different levels.

Node Communication Bridge: Enables bidirectional data transmission between the C200 controller, redundant controller chassis, and other nodes in the ControlNet network (e.g., I/O modules, third-party devices). It supports communication integration with various I/O types including Process Manager I/O and Rail I/O.

Hardware Features & Compatibility

Physical Specifications: Adopts a standard Series A chassis slot design and can be installed in chassis with 4, 7, 10, 13, or 17 slots. It is compatible with both redundant controller chassis (RCP) and non-redundant I/O chassis configurations.

Redundancy Compatibility: Only compatible with C200 controller chassis that support redundancy functions. It must be used in conjunction with a Redundancy Module (RM) to form a complete redundant control architecture.

Model Differentiation: Corresponding to the non-redundant model TC-CCN014, the suffix "R" in TC-CCR014 indicates its redundancy feature. It supports dual ControlNet cable connections and comes with a redundant media version as standard. While its cost is higher than that of the non-redundant model, it delivers superior communication reliability.

Firmware Compatibility: Pre-installed with the latest firmware at the factory, it must be matched with the Experion system version. Older system versions may require firmware downgrading via the NetworkTools utility to ensure compatibility.

Configuration Rules & Usage Requirements

Address Assignment: A unique MACID address must be configured for the module on the ControlNet network. For redundant chassis, the MAC address assignment rules must be followed (e.g., MACID 1 shall be assigned to the downstream CNI, and redundant pairs shall adopt odd-even address pairing).

Installation Position: In a redundant controller chassis, the CNI module is typically installed in designated slots (e.g., Slot 0 or Slot 3 of a 7-slot chassis). It must be installed in conjunction with modules such as the Control Processor Module (CPM) and RM. Moreover, non-redundant I/O modules are prohibited from being mixed installed in the same chassis.

Network Limitations: The number of TC-CCR014 modules supported on a single ControlNet segment is limited by the total number of network nodes (a maximum of 32 nodes for Supervisory ControlNet and 20 nodes for I/O ControlNet). In addition, the module’s address must not conflict with those of other ControlNet devices (e.g., PLCs, remote I/O units).

Cable Requirements: Redundant ControlNet cables must be used, paired with BNC connectors (e.g., TC-MC1BNC) and terminators (TC-TCXBNC). Ensure that the cable shielding layer is grounded in compliance with electrical specifications to minimize electromagnetic interference.

Application Scenarios & Advantages

Critical Process Control: Suitable for continuous production processes in industries such as petrochemicals, power generation, and metallurgy. It ensures uninterrupted transmission of control signals and measurement data, preventing production downtime caused by communication failures.

Redundant System Architecture: When paired with the C200 redundant controller chassis, it forms a fully redundant architecture from the controller to the network, meeting application scenarios with stringent SIL safety level requirements.

Hybrid Network Integration: Supports integration with a variety of I/O devices including Series A Rail I/O and Process Manager I/O, while also being compatible with third-party ControlNet devices (e.g., Allen-Bradley PLCs), making it suitable for complex industrial control network environments.

Maintenance Convenience: The module supports online Hot Swap (RIUP). However, Honeywell recommends performing maintenance operations when the system is offline to avoid process disturbances. Firmware upgrades and configuration management can be implemented via NetworkTools, reducing maintenance costs.

Customers who purchased this product are also browsing the following products:

Honeywell CC-PDOB01 24Volt Digital Output module

Honeywell MC-PDOX02 51304487-150 Digital Output Module

Honeywell TC-PPD011 51309241-125 Battery Extension Module

honeywell 05701-A-0511 16-Way Rear Access Rack

3005319639

3005319639