Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The

SCXI-1001 is a high-performance, 12-slot signal conditioning

chassis from National Instruments, specifically designed for high-channel-count data acquisition and signal conditioning applications. Boasting a robust and compact structure, a low-noise signal processing environment, flexible expandability, and multi-power supply compatibility, it serves as the core hub connecting SCXI modules and data acquisition (DAQ) devices in scenarios such as industrial testing and laboratory research and development.

This chassis supports AC power supply and realizes efficient inter-module signal transmission and synchronous control via the SCXIbus backplane architecture. It features seamless compatibility with software including LabVIEW and LabWindows/CVI, and simplifies system configuration and data acquisition processes when used with NI-DAQ drivers. Up to 8 chassis of the same series can be cascaded to meet the expansion requirements of large-scale test systems.

related documents

NI SCXI-1001.pdf

NI SCXI-1001.pdf

NI SCXI1001 Chassis Manual.pdf

NI SCXI1001 Chassis Manual.pdf

Core Features

Slot and Structural DesignIt provides 12 module slots and supports various SCXI signal conditioning modules, including thermocouple, RTD, strain gauge, high-voltage input, and digital I/O modules. It enables flexible construction of multi-channel measurement systems, suitable for high-channel-count testing scenarios.

Adopting a robust shielded enclosure design, it can effectively reduce electromagnetic interference, deliver a low-noise environment for signal conditioning, and ensure accurate acquisition of weak signals. Equipped with a forced air cooling system (including a fan and replaceable filter), it maintains a stable internal temperature for the chassis modules during long-term operation and extends equipment service life.

With physical dimensions of 24.8×43.9×17.7 cm (D × W × H) and a weight of 6.8 kg (14 lb 14 oz), it supports rack mounting or desktop placement, adaptable to diverse installation environments such as laboratories and industrial sites.

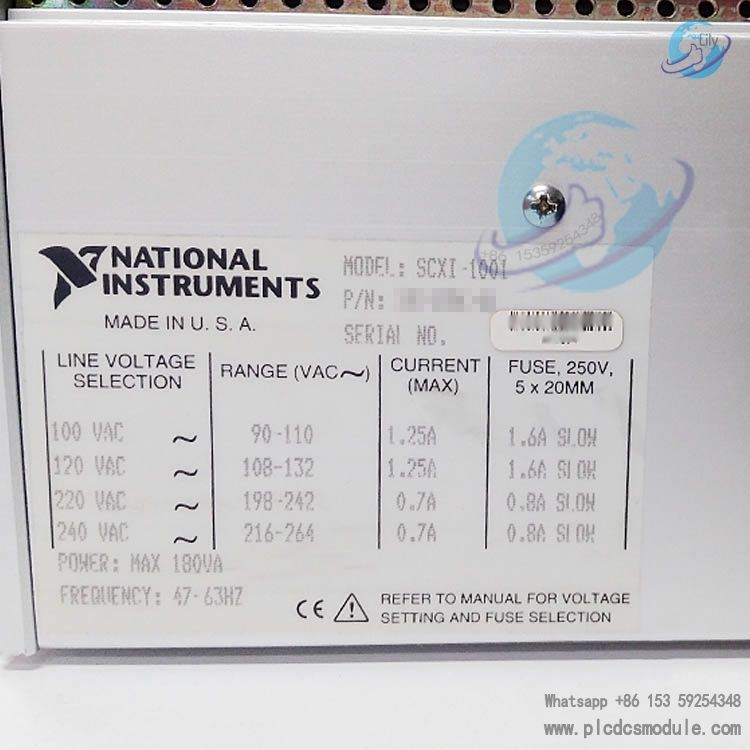

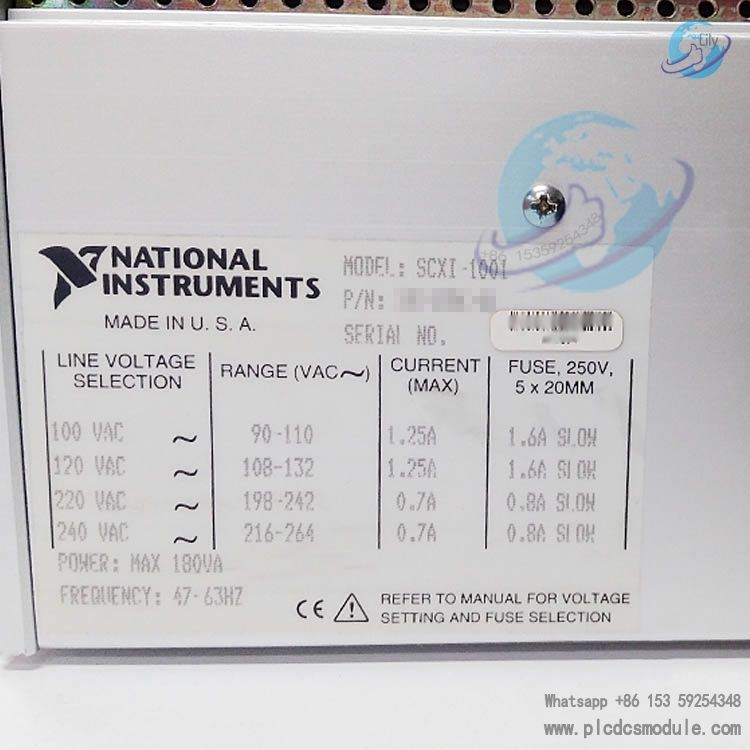

Power Supply and Electrical CharacteristicsPower Supply Method: Compatible with multi-region voltage standards including 100 VAC (Japan), 120 VAC, 220 VAC (Switzerland), and 240 VAC (Australia, Europe, North America, UK), with a frequency range of 47–63 Hz. Flexible configuration for local power grids is achievable via the voltage selector wheel, eliminating the need for additional power converters.

Power Supply Parameters: The maximum input current varies with voltage (1.75 A at 100 VAC, 1.5 A at 120 VAC, 0.8 A at 220 VAC, 0.75 A at 240 VAC). It delivers stable power to modules: +5 VDC (50 mA per slot) and ±18.5 to ±25.0 VDC (170 mA per slot). The total power dissipation is 7 W per slot, meeting the power consumption requirements of all types of SCXI modules.

Protection Mechanism: Equipped with power input fuses (5×20 mm time-delay fuses with ratings adjusted by voltage region, e.g., 2.0 A 250 V for 120 VAC) and backplane fuses (2 units, 4 A 125 V LittleFuse R251 01.5 TI). It effectively protects against circuit faults such as short circuits and overloads, safeguarding the safety of equipment and operators.

Expansion and Synchronization CapabilityMulti-Chassis Expansion: Supports daisy-chaining of up to 8 SCXI chassis, centrally controlled by a single multifunction DAQ device. It enables acquisition and control of up to 3072 channels, satisfying the requirements of large-scale distributed test systems.

Synchronization and Signal Transmission: Built-in SCXIbus backplane architecture integrates analog buses, digital control lines, and timing signal channels, realizing high-speed signal routing and precise synchronization between modules. In multiplexed mode, analog input channels of all modules can be multiplexed to a single DAQ device channel, with a sampling rate of up to 333 kS/s, suitable for high-speed data acquisition scenarios.

Module Compatibility: Compatible with all SCXI series signal conditioning modules, supporting both multiplexed mode (single DAQ device controlling multiple modules) and parallel mode (each module corresponding to an independent DAQ channel). It adapts to different signal bandwidths and sampling rate requirements.

Software and Configuration SupportDrivers and Programming Environments: Compatible with NI-DAQ 7 and later driver versions, and supports software development platforms such as LabVIEW, LabWindows/CVI, Measurement Studio, and VI Logger. It provides a rich library of functions and virtual instrument (VI) templates, simplifying chassis configuration, automatic module detection, and data acquisition program development.

Address Configuration: The chassis address can be set via front-panel DIP switches (32 optional addresses in total, with a default address of 0), supporting independent identification and communication of each device in multi-chassis systems. Revision E and subsequent versions all adopt DIP switch design for convenient operation.

Configuration Flexibility: The power supply voltage can be quickly switched via the voltage selector wheel, and the fuse replacement process is simple to facilitate on-site maintenance. Combined with accessories provided by NI (such as terminal blocks and cables with screw terminals and BNC connectors), it can flexibly adapt to connection requirements of different sensors and signal types.

Application Scenarios

High-channel-count Industrial TestingSuch as multi-sensor data acquisition and production line process monitoring in the automotive electronics and aerospace sectors.

Laboratory R&DSynchronous measurement of multiple parameters in disciplines including physics, chemistry and biology, e.g., environmental monitoring and material testing.

Portable and Field ApplicationsIt can be powered by a DC power supply via a commercially available pure sine wave DC-AC inverter, suitable for outdoor or mobile testing scenarios without AC power supply.

Mixed-signal SystemsWhen integrated with PXI devices (e.g., PXI-1010/1011 combined chassis), it enables the integrated implementation of SCXI signal conditioning, PXI data acquisition and motion control.

Key Configuration and Maintenance Points

Address SettingIn a multi-chassis system, a unique address must be assigned to each chassis. The address is calculated via the combination of 5 DIP switch positions (corresponding to values 1, 2, 4, 8, and 16). A switch in the ON position represents a valid value, while OFF represents 0. The final address is the sum of the valid values of each position.

Fan Filter MaintenanceIt is recommended to clean or replace the fan filter regularly (the power supply must be turned off and the power cord disconnected before cleaning). This prevents dust accumulation from affecting heat dissipation performance and extends the service life of the chassis and modules.

Module InstallationThe device features a non-hot-swappable design. The chassis power supply must be turned off before installing or replacing any module to avoid circuit damage. Unused slots should be fitted with filler panels to prevent dust ingress and electromagnetic interference.

Customers who purchased this product are also browsing the following products:

NI PXI-7344 PXI MOTION CONTROL MODULE

NI PXle-8135 Quad Core Embedded Controller

NI SCXI-1326 High-Voltage Terminal Block

NI SCXI-1325 HIGH-VOLTAGE TERMINAL BL0CK

![]() NI SCXI1001 Chassis Manual.pdf

NI SCXI1001 Chassis Manual.pdf

3005319639

3005319639