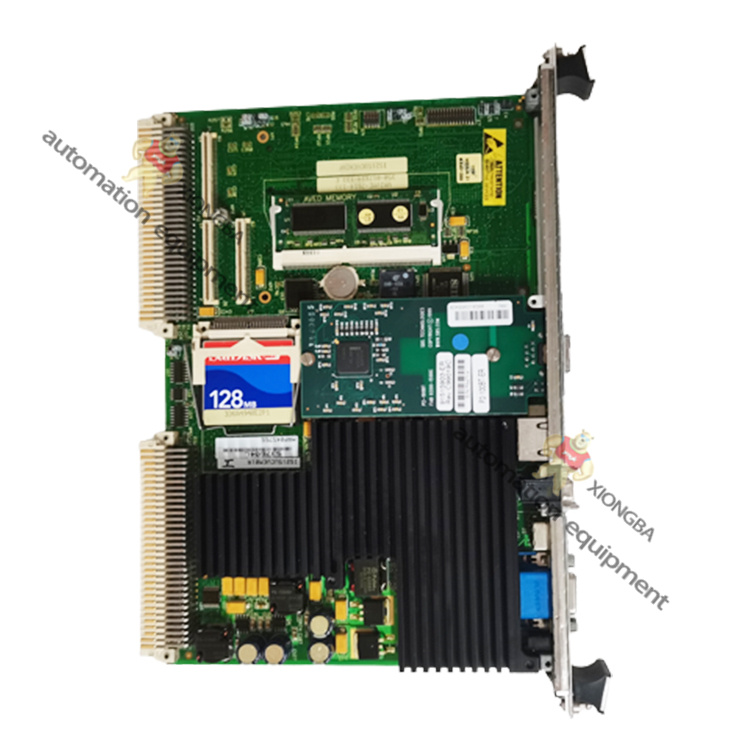

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. GE IS200VTCCH1CBB is a thermocouple input terminal board (functional abbreviation: VTCC) belonging to General Electric Mark VI Speedtronic product line. Exclusively engineered for the Mark VI turbine control system, it is primarily designed for temperature data acquisition and transmission in equipment such as gas, steam and wind turbines. The board can accurately receive and process signals from type E, J, K, S and T thermocouples, supporting up to 24 thermocouple input channels in total. It is compatible with both simplex and Triple Modular Redundancy (TMR) control architectures, boasting high compatibility and environmental adaptability, and serves as a critical component for temperature monitoring in the automated control of industrial turbines. The functional revision is C1, with functional version 2 and art version B. It is coated with a moisture-proof layer, ensuring stable operation in complex industrial environments.

Core Functions and Technical Specifications

Signal Support and Input Capability

Thermocouple Types: Compatible with type E, J, K, S and T thermocouples, supporting both grounded and ungrounded mounting. It is suitable for thermocouple signal ranges from -8mV to +45mV.

Input Channels: 24 thermocouple input channels that can be connected to DTTC (DIN European-style) and TBTC terminal boards, adapting to different installation scenarios.

Wiring Specifications: Thermocouples can be installed 300 meters away from the control cabinet, with a maximum bidirectional cable resistance of 450Ω. Thermocouple inputs exceeding hardware limits will be automatically excluded to prevent interference with other data acquisition processes.

Hardware Design and Interface Configuration

Connectors: Equipped with 6 on-board connectors (P1–P6), among which P1 and P2 are backplane connectors while the rest are for expansion connections. The front panel is fixed by screws and furnished with 3 LEDs (green/red/orange) indicating run, fault and status respectively, facilitating real-time monitoring of the board’s operating conditions.

Core Components: Integrated with Xilinx Spartan XCS30 FPGA, dual-port SRAM, CMOS static RAM and digital signal processors, ensuring efficient and stable signal processing.

Protection Design: The PCB is coated with a moisture-proof layer, featuring excellent anti-interference capability for adaptation to harsh industrial environments. It complies with safety and quality standards such as 94V0 and E99006.

Control Architecture Compatibility

It is compatible with simplex control (when paired with TBTCH1C terminal board) and Triple Modular Redundancy (TMR) control (when paired with TBTCH1B terminal board). As a Group 1 product of the Mark VI series, it is especially suitable for gas turbine control applications and can be deeply integrated with the redundant design of the Mark VI system to enhance control safety.

Installation and Maintenance Features

Installation Specifications: Inputs are connected via two I/O terminal blocks, each containing 24 terminals that can accommodate 2 #12 AWG wires. A shield termination bar is installed next to the terminal blocks and grounded to reduce signal interference.

Maintenance Convenience: The front-panel LED status indicators enable clear and rapid fault location. The moisture-proof coating minimizes the impact of ambient humidity on the circuit, extending service life. Additionally, the board supports quick assembly and disassembly to improve maintenance efficiency.

Application Scenarios

It is widely applied in the automatic control systems of gas, steam and wind turbines across industries such as power generation, chemical engineering, petroleum and natural gas. It is dedicated to temperature monitoring of critical components including turbine exhaust and bearing temperatures, providing accurate temperature data support for turbine performance optimization, fault early warning and safe operation.

Customers who purchased this product are also browsing the following products:

GE IS210MVRAH2A Mark VI Interface Board

GE IS200TRLYH1BGF Mark VI Relay Output Board

GE IS200VAICH1DAB Mark VI Analog Input/Output Board

GE IS200VRTDH1DAB Mark VI Analog Input Module

3005319639

3005319639