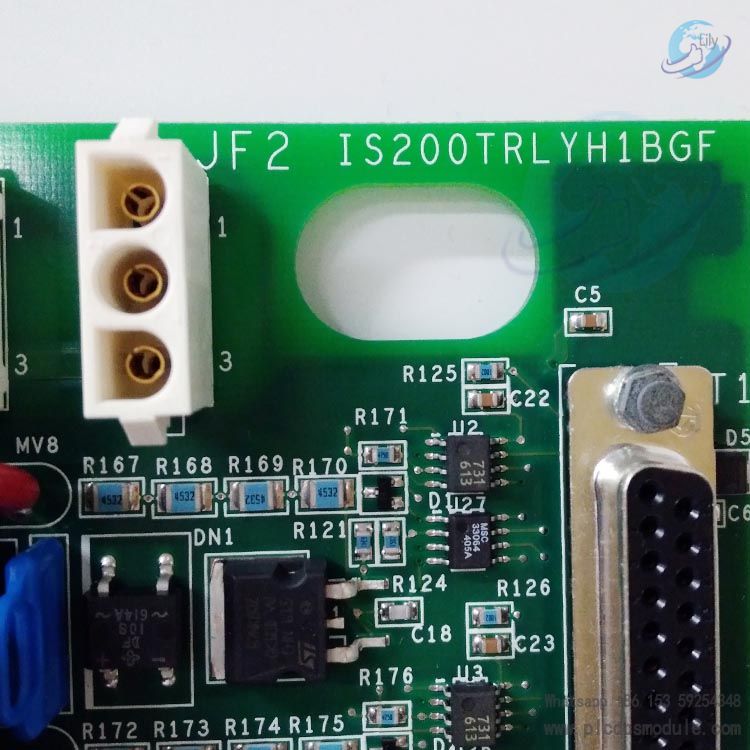

The GE IS200TRLYH1BGF Mark VI Relay Output Board is a key component specially designed by General Electric (GE) for its Mark VI control system. It plays a central role in signal transfer and device driving during the process of industrial automation. This board can accurately receive electrical signals from the controller and, through the internal relays, reliably drive external devices or circuits. It enables the precise control and stringent protection of various industrial equipment, especially steam turbines, and demonstrates outstanding performance and stability in complex industrial environments.

Technical Specifications

Relay Configuration: Onboard 48 relays, flexibly adaptable to multi-channel signal control requirements, meeting complex system wiring and control logic needs.

Contact Types: Features both normally open (NO) and normally closed (NC) contacts, providing a hardware foundation for diverse circuit connections and control strategies, compatible with startup, shutdown, and status feedback logic of different devices.

Electrical Interfaces: Supports multiple electrical interface types, enabling seamless 对接 with external devices of varying voltage and current ratings, reducing system integration complexity.

Key Features & Advantages

Industrial-Grade Rugged Design: From component selection to PCB layout, adheres to stringent industrial standards, ensuring stable operation in harsh conditions such as extreme temperatures (-20°C to +60°C), high humidity, and strong electromagnetic interference, significantly minimizing downtime caused by environmental factors.

High-Reliability Operation: Incorporates redundant design throughout, with backup mechanisms for critical circuits and components. Even if partial relays or lines malfunction, the system maintains basic control functions to safeguard production continuity.

Easy Installation & Maintenance: Utilizes standardized DIN rail mounting, requiring only snap-in installation onto the rail and wiring—no complex tools or operations needed. Clear labeling and modular structure facilitate rapid fault location and damaged component replacement.

Technical Parameters

Rated Voltage: It is compatible with common industrial voltage levels and has a flexible input voltage range, enabling stable operation in different power supply environments.

Rated Current: The relay contacts can carry a relatively large current, meeting the requirements for driving high-power equipment. The specific values may vary slightly depending on different models.

Response Time: The response time from receiving the control signal to the operation of the relay is extremely short, enabling rapid start-stop and precise control of equipment, which is well-suited for industrial scenarios with high real-time requirements.

Insulation Resistance: It features high insulation resistance, effectively isolating different circuits to prevent electric leakage and crosstalk, thereby enhancing the safety and stability of the system.

Application Areas

Power Industry: In power plants, it is used for the control and protection of key equipment such as steam turbines and generators, ensuring the stable production and supply of electricity.

Industrial Automation Production Lines: It realizes the logical control of automated equipment, such as the start and stop of motors, the opening and closing of valves, etc., helping to improve production efficiency and product quality.

Petrochemical Field: It can adapt to the high-temperature, high-pressure, and highly corrosive environment of petrochemical production, participating in the control of various equipment such as pumps and compressors to ensure the safe and stable operation of the production process.

Customers who purchased this product are also browsing the following products:

GE IS200TRPGH1BDD MRPB01499 Mark VI Trip Solenoid Control Board

GE IS220YAICS1A Mark VleS Control Analog I/O Module

Honeywell PSU-240516 | FS-PSU-240516 | Power Supply

BENTLY NEVADA 3500/42M 176449-02 Proximitor Seismic Monitor

ABB PM856AK01 3BSE066490R1 AC800M Processor Unit PLC

3005319639

3005319639