GE RS-FS-9001 is a universal flame detector developed by GE Reuter-Stokes. It is mainly used for flame monitoring in industrial fields and ensures the safe operation of equipment such as gas turbines.

Mechanical Specifications: The main body mounting material is AISI316 stainless steel, and the housing is AISI304 stainless steel (sealed and filled with argon). The process connection is a 3/4" NPT female thread, the electrical connector is MIL-C-38999 Series III, size 15 (5-pin), and the window material is sapphire.

Electrical Specifications: The sensor is a silicon carbide photodiode, with an output of 4 - 20 mA DC current, and the maximum is less than 21 mA. The response time is less than 25 milliseconds, and the power supply requirement is 12 - 30 VDC (more than 100 mA).

Environmental Specifications: The operating temperature range is -40°C to 150°C (ambient temperature), and can reach 235°C with specified water cooling; relative humidity is 100% non-condensing; process pressure is 400 psig (2.8 MPa); it can withstand certain vibrations (0.1 inch DA at 10 – 40 Hz, 8 G continuous at 40 – 2000 Hz, 14 G peak).

data sheet

Working principle: A silicon carbide photodiode is used to detect ultraviolet rays generated by flames. The sapphire window allows ultraviolet rays to pass through, and the internal lens focuses the light onto the photodiode. The photodiode is connected to a MOSFET input amplifier, which can automatically adjust the gain to adapt to different light intensities. The sensor adjusts the supply current according to the intensity of ultraviolet rays, and transmits power and signals through two wires.

Installation: For mechanical installation, if the ambient temperature is too high and cooling is required, there are three cooling methods (water cooling, ambient air cooling, and pressurized air cooling). Use specific cables for electrical connections, and connect them according to the specified polarity and grounding requirements. After installation, sensor detection and controller settings must be performed.

Maintenance: Avoid disconnecting the connector when the circuit is energized (unless the area is non-hazardous). Do not operate the sensor and cables outside the operating temperature range. Clean the lens regularly, and apply anti-seize compound to the threads during installation.

Troubleshooting: Common problems include no current flow (which may be caused by reversed polarity or open wires; check and correct the polarity and inspect connections), low sensitivity (which may be due to a dirty lens or cable grounding; clean the lens and check the cable grounding), low flame intensity signal (which may result from misalignment of the sensor installation; check the perpendicularity of installed components and the sensor's field of view), and periodic low readings on the secondary side of DLN1 turbines (which may be caused by lens condensation under high humidity; replacing the short installation pipe can improve this issue).

Main Features:

High Sensitivity: Capable of detecting weak flame signals, suitable for various combustion applications.

High Temperature and Pressure Resistance: Can withstand high-temperature and high-pressure environments exhausted by compressors.

Compact Structure: Adopts a stainless steel housing and a sealed design, with strong corrosion resistance.

Easy Installation and Maintenance: Uses standard NPT pipe thread connections for convenient installation and disassembly.

Application scenarios: It is often used in gas turbines, and also applicable to industrial fields such as petroleum, natural gas, and iron smelting. It can detect flames in environments with fuel, steam, or water mist.

Customers who purchased this product are also browsing the following products:

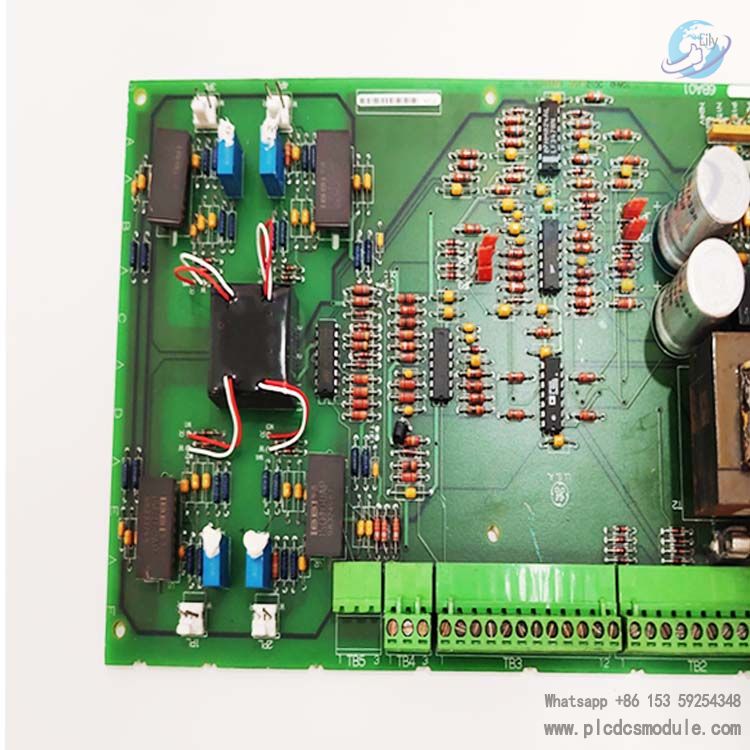

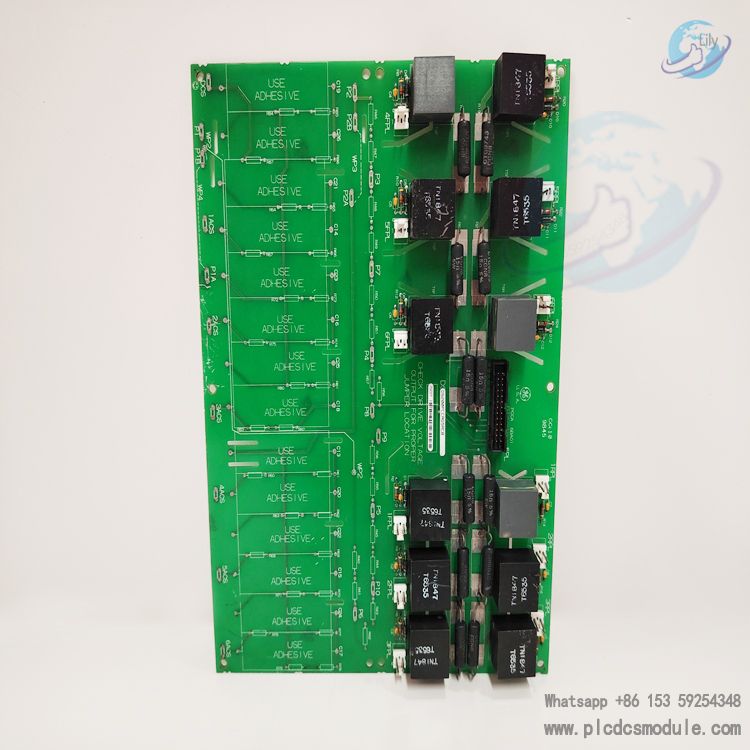

GE DS200FGPAG1AHD Mark VI Gate Pulse Amplifier Board

GE SR760-P5-G5-S5-HI-A20-R-E Multilin 760 Feeder Management Relay

Honeywell CC-PAIH01 51405038-175 Hart analog input module

ABB PPD239 A1106 PEC80-MINI 3BHE029594R1106 AC 800PEC excitation control

3005319639

3005319639