Built with non-incendive field circuit design, the module supports the connection of 2-wire, 3-wire, or 4-wire transmitters, enabling stable operation in harsh industrial environments and hazardous areas. It also integrates HART pass-through, data acquisition, and status reporting functions in one unit, delivering accurate and reliable signal monitoring and device communication solutions for process automation systems. The module is widely suitable for industries with high requirements for safety and data integrity, such as petrochemicals, power generation, and smart manufacturing.

related documents

![]() PAC8000 SafetyNet IO Modules.pdf

PAC8000 SafetyNet IO Modules.pdf

Product Features

Safety Certification and Compliance

- Safety Level CertificationIt is certified for SIL 2 safety-related applications and adopts a 1oo1D architecture to ensure system safety performance. The certification is based on the module’s superior design itself and does not rely on "operational validation" data, thus meeting the compliance requirements of safety-critical scenarios.

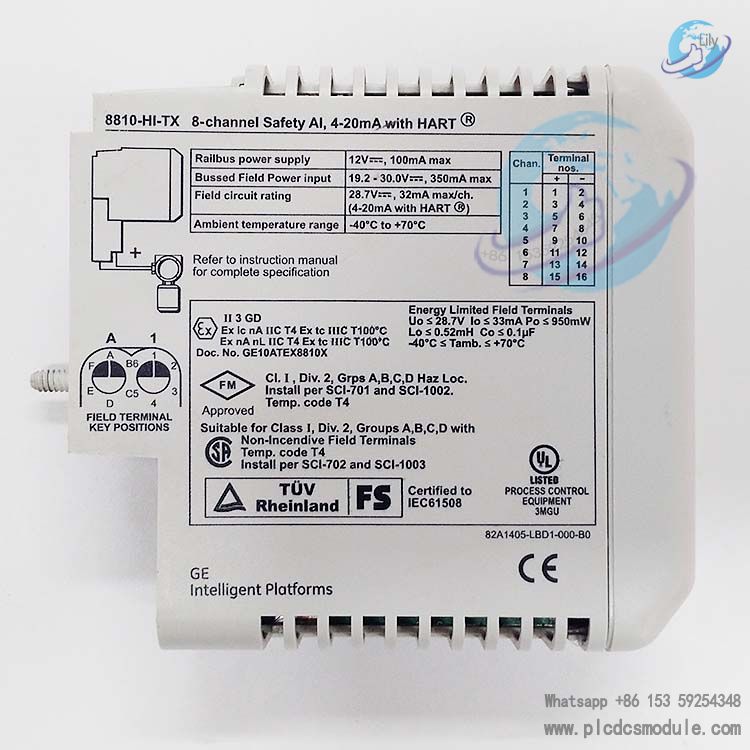

- Hazardous Area CompatibilityIt complies with the ATEX standard, with protection technology designated as EEx nA [nL] IIC T4. Classified as Class 1, Div. 2, Grps A, B, C, D T4 hazardous areas under FM and CSA certifications, it supports installation and maintenance in Zone 2/Division 2 hazardous environments. The field wiring can be configured as either intrinsically safe (Exi) or increased safety (Exe) type.

Channel and Signal Specifications

- Channel ConfigurationThe module is equipped with 8 single-ended input channels, with a nominal signal range of 4–20mA and an extended full signal range of 0.25–24mA, making it flexibly compatible with various standard 4–20mA industrial transmitters.

- Accuracy and StabilityAt 25℃, it achieves a measurement accuracy of ±0.1% of the range, with a temperature coefficient of 38 ppm/℃ and a repeatability of 0.05% of the range. The 16-bit resolution ensures high precision of signal acquisition. It also boasts excellent environmental adaptability, being resistant to extreme temperatures, humidity, corrosion, shock, and vibration.

- Line Fault MonitoringBuilt-in line fault detection functionality features a short-circuit current threshold of >23.5mA and an open-circuit current threshold of <0.5mA. It can identify on-site wiring abnormalities in real time and provide feedback, ensuring the operational reliability of the system.

HART Function Support

- Protocol CompatibilityIt supports HART protocol pass-through, data acquisition, and status reporting (Note: The initial version of SafetyNet does not implement complete HART functions; please consult GE official for details). It is capable of communicating with HART smart instruments of protocol version 5.0 and above.

- Data FormatHART data is transmitted in IEEE754 floating-point format, enabling the acquisition of dynamic variables and status information of instruments. This provides data support for remote device management, calibration, and advanced diagnostics.

Power Supply and Electrical Isolation

- Power Supply RequirementsThe typical current of the system power supply is 50mA, with a maximum of 70mA. The Bus Field Power (BFP) supply must be 24VDC, provided by the MTL 8914-PS-AC power unit. The maximum supply current for 2-wire transmitters is 350mA, and 110mA for 4-wire transmitters. It supports redundant power supply configuration to enhance power supply reliability.

- Electrical IsolationEach channel is equipped with 250VAC RMS isolation from the Railbus, effectively preventing electromagnetic interference and voltage surges from affecting the module and the system, and ensuring the stability of signal transmission.

Status Indication and Diagnostics

- LED IndicatorsThe module is fitted with LED indicators for power (green), fault (red), and channel status (yellow). A lit power indicator signifies normal power supply. The status of the fault indicator reflects the module’s operating mode: steady on indicates fail-safe mode, off indicates normal operation, equal-duty-cycle flashing indicates cold start in progress, and Morse code "A" flashing indicates a fault state after a controlled shutdown. This facilitates quick on-site troubleshooting.

- Built-in DiagnosticsIn addition to line fault monitoring, the module is equipped with comprehensive internal diagnostic functions. If a fault affecting safety functions is detected, it will trigger a controlled shutdown or switch to fail-safe mode, while recording fault data for traceability.

Operating Modes and Response Characteristics

Fail-Safe Mode

Response Time

- In 4–20mA mode, the maximum response time from signal change to Railbus availability is 25ms, ensuring fast acquisition and transmission of real-time signals.

- In HART mode, the response time per channel is 0.75s, which meets the real-time requirements for data interaction with HART instruments.

Physical and Installation Specifications

Module Dimensions

Installation Compatibility

Wiring Terminals

Application Scenarios and System Integration

Meanwhile, the module can be paired with PAC8000 series Bus Interface Modules (BIM), supporting multiple communication protocols including PROFINET, Modbus RTU, PROFIBUS DP, and Modbus TCP/IP. It is compatible with distributed control architectures and meets the requirements for remote I/O deployment.

Recommended Products of the Same Brand and Series: GE PAC8000 Product Line

I. Safety I/O Modules (for SIL 2 Safety-critical Scenarios)

- 8202-HO-IS 8-channel Safety Analog Output Module (4-20mA, HART-enabled)Core Features: Equipped with 8 single-ended output channels, it features a nominal signal range of 4–20mA and a full signal range of 1–22mA, supporting HART pass-through and status reporting. It adopts intrinsically safe (EEx ia) IIC-rated field circuits, making it suitable for high-risk areas such as Zone 0/Div 1. The module is integrated with open-circuit fault detection (triggered when load resistance exceeds 685Ω). Its fail-safe mode can be configured as upscale, downscale or last value hold. The maximum load resistance per channel is 650Ω, with a minimum load voltage of 13V at 20mA output.Environment and Reliability: Operating temperature ranges from -40℃ to +70℃, with shock resistance of 30g and vibration resistance of 5g, complying with ISA G3 corrosion resistance standards. The Mean Time Between Failures (MTBF) reaches 40.8 years at 20℃ and 33 years at 30℃, making it ideal for long-term stable operation.Application Scenarios: It is used in conjunction with the 8810-HI-TX-01 to output 4–20mA signals for actuators in safety systems, such as I/P converters and safety valve actuators. It is particularly suitable for safety control in hazardous areas including petrochemical wellheads and gas gathering stations.

- 8811-IO-DC 8-channel Safety Discrete Input/Output Module (24VDC)Core Features: All 8 channels can be independently configured as input or output. The input supports dry contact switch signals; the output can deliver a continuous current of 2A per channel and a total continuous current of 6A for the module (8A non-continuous for <10s). It is built with line fault monitoring (open-circuit/short-circuit detection) and ground leakage detection functions, with adjustable input filter time ranging from 0s to 8s. Compliant with SIL 2 certification and EEx nA nL IIC T4 protection standards, it is applicable to Zone 2/Div 2 hazardous areas.Key Parameters: The typical input turn-on threshold current is 0.9mA, the minimum detectable pulse width is 5ms, and the maximum frequency in pulse counting mode is 30Hz. The output can be configured as discrete signal, pulse signal or custom mode, with adjustable pulse width from 1ms to 60s.Application Scenarios: It is used for discrete signal acquisition and control in safety systems, such as emergency shutdown button signal input and on-off control of safety interlock valves. It can complement the analog monitoring function of the 8810-HI-TX-01 to build a complete safety loop of analog monitoring + discrete control.

- 8201-HI-IS 8-channel Intrinsically Safe Analog Input Module (4-20mA, HART-enabled)Core Features: With 8 single-ended input channels, it is specially designed for intrinsically safe scenarios. The field circuit has a protection class of EEx ia IIC, allowing direct connection to 2-wire transmitters in Zone 0/Div 1 hazardous areas. It has a nominal signal range of 4–20mA and a full signal range of 0.5–22mA. The minimum transmitter supply voltage is 15V at 20mA input, with built-in open-circuit (current < 0.5mA) and short-circuit (current > 21.5mA) fault detection.Accuracy and Stability: The accuracy is ±20μA at 25℃, with a temperature stability of ±0.006% of range/℃ within -40℃~+70℃ and 16-bit resolution. It supports HART pass-through and variable status reporting, with a channel response time of 0.75s per channel in HART mode.Application Scenarios: When the 8810-HI-TX-01 needs to be extended to higher-risk Zone 0/Div 1 areas, this module can be paired with it to achieve intrinsically safe signal acquisition, such as signal monitoring of close-range high-risk equipment including wellhead pressure transmitters and storage tank level transmitters.

II. General-purpose I/O Modules (for Conventional Control Scenarios)

- 8101-HI-TX 8-channel Analog Input Module (4-20mA, HART-enabled)Core Features: Functionally similar to the 8810-HI-TX-01 but without safety certification, it has 8 single-ended input channels, supporting 2-wire/4-wire transmitters, with a nominal signal range of 4–20mA and a full signal range of 1–23mA. The accuracy is ±0.1% of range at 25℃ with 16-bit resolution. It supports HART protocol (compatible with protocol version 5.0 and above) and can collect dynamic variables and status information of instruments.Practical Functions: It has four-level alarms (high/low/high-high/low-low) with user-customizable alarm deadband. It is integrated with line fault detection (open-circuit < 0.5mA, short-circuit > 23.5mA), and the fault mode can be configured as downscale, upscale or last value hold. Supporting online hot swapping, the module and carrier adopt a keyed design to prevent misplugging.Application Scenarios: Used for conventional process parameter monitoring, such as signal acquisition of temperature, flow and pressure transmitters in factory workshops. It can serve as an extension module of the 8810-HI-TX-01 in non-safety areas to reduce the overall system cost.

- 8115-DO-DC 8-channel Discrete Output Module (2-60VDC)Core Features: Equipped with 8 non-isolated sourcing output channels, it has an output voltage range of 2–60VDC, a continuous switching current of 1A per channel, and can withstand 4A current for a short period (<100ms), with a total module switching current of 6A (<20ms). Adopting solid-state relay output, it has no mechanical contact wear, improving long-term reliability.Flexible Configuration: The output mode supports discrete signal, instantaneous pulse or continuous pulse, with adjustable pulse width from 2ms to 130s. It has overcurrent and short-circuit protection, with OFF-state leakage current < 1mA and ON-state voltage drop < 0.25V (max).Application Scenarios: Used for controlling conventional discrete actuators such as solenoid valves, indicator lights and small motor start-stop. It can link with the process parameters monitored by the 8810-HI-TX-01 to realize automatic control logic (e.g., triggering valve closure when flow exceeds the limit).

- 8123-PI-QU 2-channel Pulse/Quadrature Input ModuleCore Features: It has 2 pulse counting input channels (1 channel in quadrature mode), with a maximum pulse frequency of 50kHz (normal mode) and 12.5kHz (quadrature mode). It supports multiple signal types including current pulse (4-20mA), voltage pulse (0-24VDC) and NAMUR proximity switches. Equipped with a 32-bit counter, it supports up/down counting and can measure frequency, acceleration and cumulative pulse count.Diagnostics and Expansion: Supporting open-circuit, short-circuit and pulse loss fault detection, it is provided with 2 retransmission output channels (max frequency 2kHz) to retransmit collected pulse signals to other devices. The module has a built-in gating input to control the start and stop of the counter.Application Scenarios: Used for pulse signal acquisition scenarios such as flow measurement and speed monitoring, e.g., pulse counting of turbine flowmeters and motor speed feedback. It can complement the 4-20mA analog flow signal of the 8810-HI-TX-01 to achieve dual monitoring of analog trend + pulse accurate measurement.

III. Power Supply and Controller Modules (Core System Support)

- 8914-PS-AC 24VDC Bus Field Power Supply ModuleCore Features: Specifically designed for PAC8000 safety I/O modules, it outputs 24VDC DC power to supply Bus Field Power (BFP) for modules such as the 8810-HI-TX-01 and 8202-HO-IS. The input voltage range is 85–264VAC, and the output current is adapted to the requirements of different modules (e.g., the maximum BFP current of the 8810-HI-TX-01 is 350mA for 2-wire systems and 110mA for 4-wire systems).Safety and Redundancy: Compliant with intrinsically safe-related standards, it supports redundant configuration (2 modules in parallel) and has overcurrent, overvoltage and short-circuit protection. The operating temperature ranges from -20℃ to +70℃, and the storage temperature ranges from -40℃ to +85℃, adapting to harsh industrial environments.Application Scenarios: As the dedicated power supply for safety I/O modules, it ensures the stable power supply of the field circuits of modules like the 8810-HI-TX-01, avoiding signal acquisition accuracy degradation caused by external power fluctuations. It is an essential component for SIL 2 system power supply.

- 8913-PS-AC Multi-output Power Supply Module (12VDC+24VDC)Core Features: Adopting a dual-output design, it provides 12VDC (6A) and 24VDC (5A) power, supplying power to the PAC8000 system bus (Railbus) and general-purpose I/O modules respectively. The input voltage range is 85–264VAC, with an efficiency of ≥85% (up to 95%). It supports DIN rail mounting and is equipped with an RS485 communication interface for remote monitoring of power supply status.Protection Functions: Integrated with overcurrent, overvoltage and short-circuit protection, it supports optional redundant configuration. Compliant with industrial-grade anti-interference standards, it adapts to voltage fluctuations and electromagnetic interference environments.Application Scenarios: It supplies power to general-purpose I/O modules (e.g., 8101-HI-TX, 8115-DO-DC) and system communication components. Cooperating with the 8914-PS-AC, it realizes separate power supply for safety loop + conventional loop, improving system reliability.

- PAC8000 Redundant Controller (e.g., 8002-CC-85)Core Features: It adopts an IBM PowerPC 266MHz 32-bit processor (equivalent to Pentium 512MHz in performance) with 25M memory, supporting dual Ethernet and 4 serial interfaces (RS232/422/485), and is compatible with multiple protocols such as Modbus TCP/RTU, HART and PROFINET. It supports redundant configuration (2 controllers in hot standby mode), a single controller can support up to 64 I/O modules, and online hot swapping is available.Data Processing Capability: Equipped with high-speed data acquisition and logic operation functions, it supports Sequence of Events (SOE) recording, with analog SOE resolution reaching the millisecond level. It can synchronously record the analog signals collected by the 8810-HI-TX-01 and the switching signals of discrete modules, facilitating fault traceability.Application Scenarios: As the core of the PAC8000 system, it is responsible for receiving data from the 8810-HI-TX-01 and other I/O modules, executing control logic and safety interlock programs. It is suitable for small and medium-sized process control systems (e.g., gas gathering station SCS, chemical plant unit control).

3005319639

3005319639