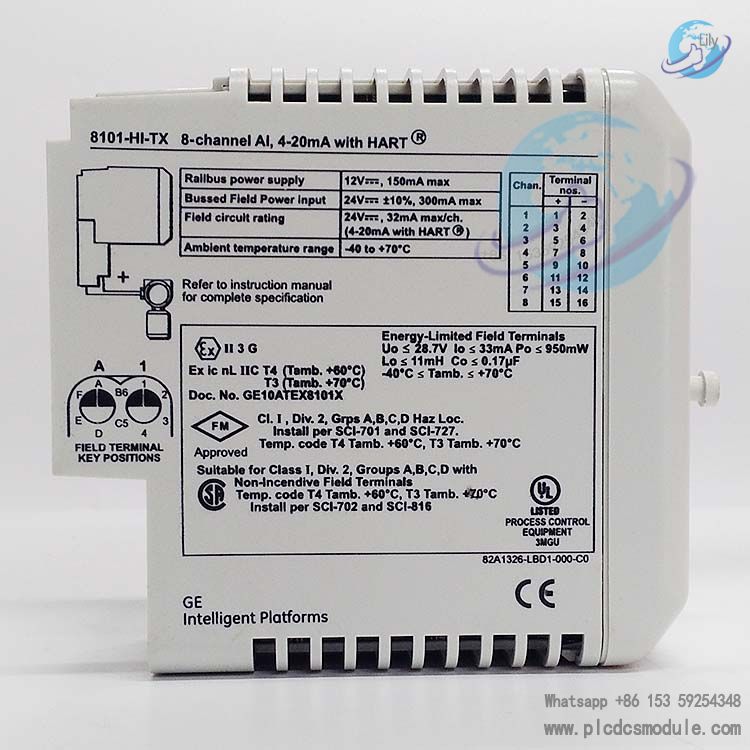

The GE 8101-HI-TX is a core 8-channel analog input module belonging to the PAC8000 modular I/O product line. Engineered specifically for industrial automation and process control applications, it is compatible with both 2-wire and 4-wire transmitters, and is equipped with HART protocol pass-through and variable status reporting functions. Meanwhile, it integrates non-incendive field circuits and line fault detection mechanisms. Capable of stably acquiring 4-20mA analog signals in industrial settings such as oil and gas, chemical processing, and power generation, this module delivers high-precision and highly reliable data input support to the system, and serves as a critical component for realizing automation and intelligent operation of production processes.

related documents

Technical Specifications

- Input Channels and Signal RangeChannel Configuration: The module features 8 single-ended input channels, which can independently acquire signals from different transmitters and support simultaneous processing of multi-channel analog data to improve the signal acquisition efficiency of the system.

- Signal Range: The nominal signal range is 4–20mA (an industry-standard analog signal interval), and the full signal range can cover 1–23mA. It is capable of over-range signal acquisition, making it suitable for transmitter output requirements in more industrial scenarios.

- Line Fault DetectionIt is equipped with dual fault detection functions for open-circuit and short-circuit conditions, which can conduct real-time monitoring of line abnormalities and feed back status information to ensure the stability of signal acquisition:

- Short-circuit Detection: When a line short-circuit occurs and the current exceeds 23.5mA, the module can quickly identify the fault and trigger corresponding alarms.

- Open-circuit Detection: When a line open-circuit occurs and the current is less than 0.5mA, the module can also capture the fault signal in a timely manner, facilitating troubleshooting by operation and maintenance personnel.

- Output and Power Supply ParametersOutput Performance: Under the input condition of 20mA, the minimum output voltage is 13.5V and the maximum output current can reach 32mA, providing stable power supply support for transmitters.Power Supply Requirements: The module requires an external 24V DC bus field power supply. Within the voltage fluctuation range of 24V DC ±10%, it can operate normally with a maximum power consumption current of 300mA for 2-wire transmitters and 60mA for 4-wire transmitters. Meanwhile, it relies on Railbus (12V) for power supply, with a typical operating current of 100mA and a maximum current of 150mA to ensure the stable operation of the module itself.

- Accuracy and Repeatability

- Accuracy: Within the full operating temperature range, the measurement accuracy is ±0.1% of the range, which can effectively reduce signal conversion errors, ensure data acquisition accuracy, and meet the high-precision data requirements of industrial process control.

- Resolution: It features 16-bit resolution, enabling fine quantization of analog signals and capturing tiny signal changes, which is suitable for scenarios with high parameter sensitivity requirements.

- Repeatability: The repeatability is 0.05% of the range, which means that when measuring the same signal multiple times, the result deviation is extremely small and the data consistency is high, thus improving the data reliability of the system.

- Response TimeThe response speed varies according to different operating modes, which can adapt to scenarios with different real-time requirements:

- 4–20mA Mode: The maximum response time from signal change to Railbus availability is 27ms, which can transmit signals quickly to meet the control scenarios with high real-time requirements.

- HART Mode: The response time per channel is 0.75s. Although slower than the pure 4–20mA mode, it can simultaneously realize HART protocol communication functions, balancing real-time performance and intelligent requirements.

- Isolation PerformanceThere is 100V AC isolation between the channels and Railbus, which can effectively resist electromagnetic interference from the Railbus side and prevent interference signals from affecting the signal acquisition accuracy of the input channels.No isolation is designed between channels, so attention should be paid to avoiding signal crosstalk between channels during wiring. It is recommended to reasonably plan the wiring according to the on-site electromagnetic environment.

Configurable Parameters

Functional Features and Advantages

- HART Protocol SupportThe module is equipped with HART protocol pass-through functionality, enabling two-way communication with HART smart transmitters. On the one hand, it can acquire 4–20mA analog signals from transmitters; on the other hand, it can retrieve device information, process variables, diagnostic data, and more from transmitters via the HART protocol. It also supports sending configuration commands (such as range adjustment and zero calibration) to transmitters, which enhances the system’s intelligence and facilitates remote operation, maintenance, and equipment management.

- High Adaptability and Reliability

- Environmental Adaptability: The non-incendive field circuit design and hazardous location certification (Class 1, Div 2/Zone 2) allow the module to operate safely in harsh industrial environments such as flammable and explosive areas.

- Stability Assurance: The integrated design of high-precision analog-to-digital converters, line fault detection, and isolation protection minimizes errors and interference throughout the entire signal acquisition, transmission, and processing process. This ensures the module’s long-term stable operation and reduces the probability of unplanned downtime caused by faults.

- Easy Installation and Maintenance

- Compact Design: With a narrow width of 42mm and lightweight construction (200g), it saves cabinet space and facilitates installation in dense I/O module layouts.

Diagnostics and Maintenance: The onboard fault detection and alarm functions enable quick identification of line or module abnormalities. Additionally, the module supports flexible channel status configuration, allowing operation and maintenance personnel to activate or deactivate channels as needed, which simplifies the maintenance process.

Application Fields

With its high precision, high reliability and rich functionality, the 8101-HI-TX module is widely used in various industrial automation and process control scenarios. Its core application fields are as follows:- Petrochemical Industry: It is used to collect transmitter signals of process parameters such as pressure, flow rate and liquid level—including reactor pressure monitoring and pipeline flow measurement—and provides data support for production process control and safety monitoring.

- Power Industry: It is compatible with temperature and pressure transmitters in power plants, collecting operating parameters of critical equipment such as steam turbines and boilers, which helps ensure the stable operation of power systems and enables fault early warning.

- Metallurgical Industry: It monitors process parameters such as temperature and liquid level during smelting, such as blast furnace liquid level monitoring and rolling mill temperature acquisition, ensuring the stability of metallurgical processes and improving product quality.

Other Industrial Fields: In industries such as water treatment, food processing and pharmaceuticals, it can collect signals from various process sensors, providing accurate data input for automated control systems and driving the standardization and intelligentization of production processes.

Customers who purchased this product are also browsing the following products:

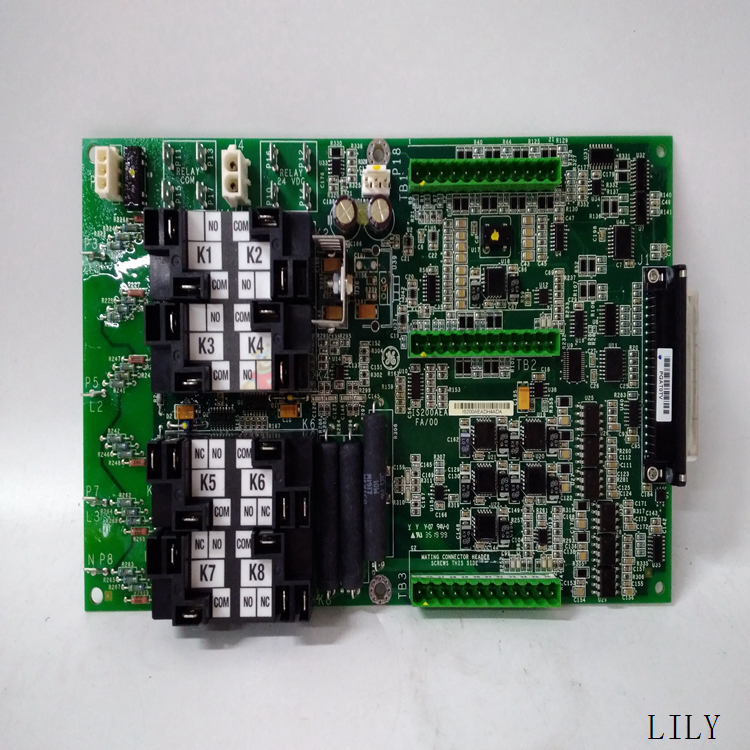

GE IS200VVIBH1CAC Mark VI Circuit board module

3005319639

3005319639