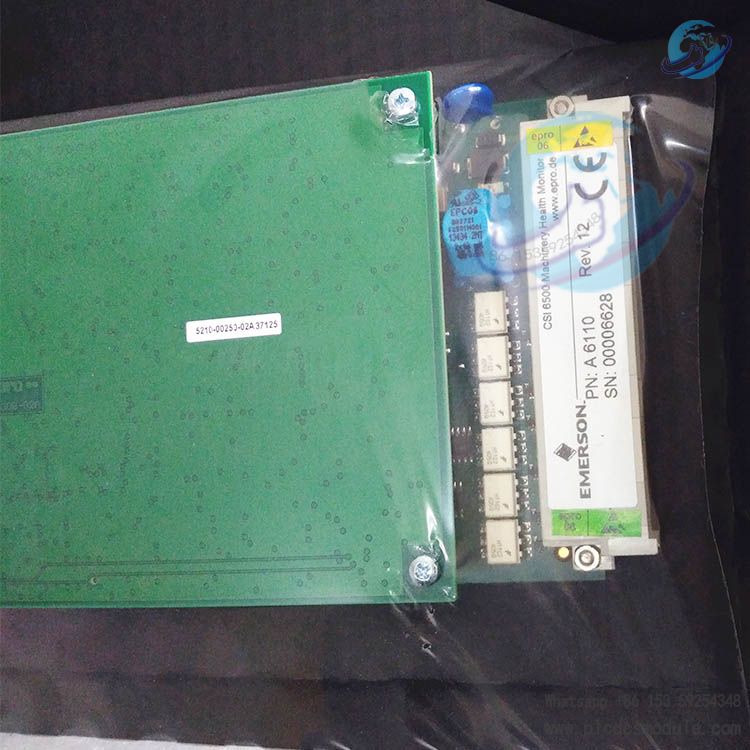

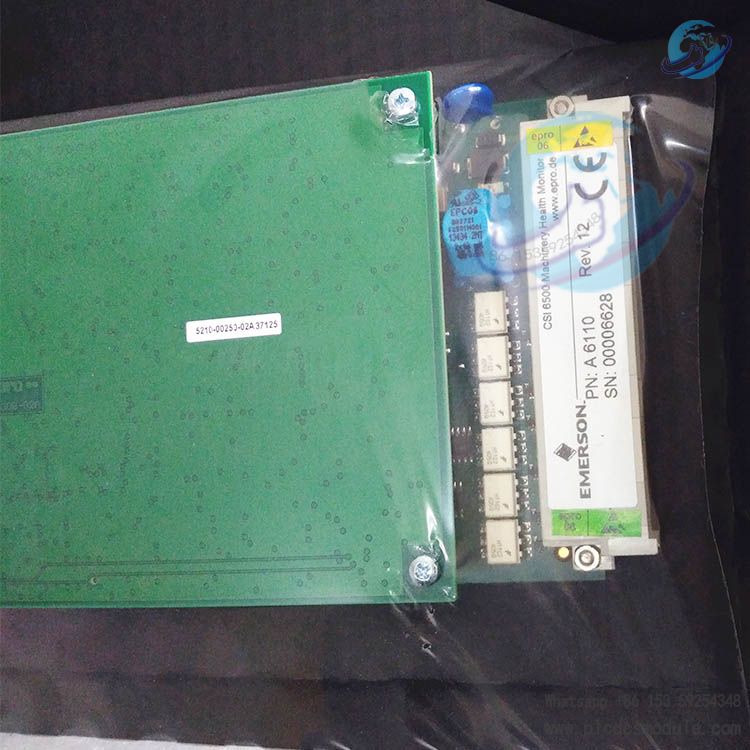

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The

A6110 is a 1-slot shaft relative

vibration monitor launched by Emerson, specifically designed for the AMS 6500 Machinery Health Monitoring System. Its core positioning is to provide highly reliable vibration monitoring and protection for critical rotating machinery in factories. Ultimately, it can be combined with other AMS 6500 monitors to build a complete machinery protection and monitoring system that complies with the API 670 standard.

Its core application scenarios cover various types of high-value rotating equipment, including:

Steam Turbines: Mainly used for power output in power plants and large industrial enterprises. They drive mechanical operation through energy conversion and are core equipment for energy supply.

Gas Turbines: Primarily utilized for power generation in power stations and power output in large industrial facilities. By converting energy to drive mechanical operation, they serve as core equipment for energy supply.

Compressors: Used for compressing gases (such as air, natural gas, process gases, etc.), and are indispensable in fields like oil extraction, chemical synthesis, and refrigeration.

Hydraulic Turbine Units: Driven by the energy of water flow to rotate and generate electricity, they are the core equipment of hydropower stations and key devices for clean energy utilization.

DATA SHEET

EMERSON A6110 9199-00001.pdf

EMERSON A6110 9199-00001.pdf

Shaft relative vibration monitoring is implemented by displacement sensors, which can be installed in two ways:

Mounted through the bearing housing;

Built into the bearing pedestal, with the rotating shaft as the measurement target.

The sensors adopt non-contact eddy current differential sensors to measure the position and motion state of the shaft. Since the sensors are fixed on the bearings, the monitored parameters reflect "the vibration of the shaft relative to the bearing housing" (i.e., shaft relative vibration), which is different from "shaft absolute vibration" (which needs to consider the vibration of the bearing housing itself).

The selection criteria for the two vibration monitoring methods are as follows:

- Accurate Monitoring: Collect real-time shaft relative vibration data and support multi-mode measurement (such as zero-peak value, peak-to-peak value);

- Reliable Protection: Compare vibration parameters with alarm thresholds, trigger alarm signals and relay actions to prevent equipment damage caused by overload;

- System Integration: As a core component of PlantWeb and AMS software, it can be linked with Ovation and DeltaV process control systems. Meanwhile, it provides predictive diagnosis tools for operation and maintenance personnel to identify equipment faults in advance;

- Self-Diagnosis: Monitor hardware status, power input, hardware temperature, sensor and cable connections in real time to ensure the reliability of its own operation.

- Eddy Current Differential Sensor: A type of non-contact sensor that uses the eddy current effect to measure the distance between the sensor probe and the measured conductor (rotating shaft). It features high precision, fast response and strong anti-interference ability, making it widely used in industrial shaft vibration monitoring.

- Peak-to-Peak Value: A common vibration amplitude parameter, referring to the difference between the maximum positive value and the maximum negative value of the vibration displacement waveform in a cycle, which can directly reflect the total range of shaft vibration.

- Predictive Diagnosis: A proactive equipment maintenance technology that analyzes the collected operation data (such as vibration, temperature) to predict potential faults of equipment, helping to arrange maintenance plans reasonably and reduce unplanned downtime.

- LED Indicators: 2 green LEDs (indicating "normal" status of the 2 channels respectively), 2 red LEDs (indicating "alert/danger" status of the 2 channels respectively);

- Buffered Outputs: 2 channels, consistent with sensor input signals, range ±10 V, load >100 kΩ, frequency range 0.1-5 kHz (-3 dB), 0-16 kHz (-3 dB±20%);

- Configuration Interface: Mini DIN socket (RS-232 protocol), used for module configuration, parameter reading and status monitoring;

- Operating Handle: Facilitates module insertion and removal, and can be used to attach module/sensor identification labels.

Analysis Functions

(1) Measurement Modes

Supports hot configuration (no shutdown required), including:

Independent dual-channel mode: zero-peak value, peak-to-peak value;

Combined dual-channel mode: Smax (DIN 45670A), Smax peak-to-peak value (DIN 45670B, VDI 2059), Smax zero-peak value (VDI 2059);

API 670 standard mode: True S peak-to-peak value (Y/X axes independent).

(2) Analysis Parameters

Harmonic analysis: 1/2x, 1-10x harmonics and corresponding phase angles;

Data output: Supports ModBus TCP/IP protocol transmission.

Notes on Key Terms

Hot Configuration: The ability to modify system settings or configurations while the equipment is in operation without the need for shutdown, ensuring continuous operation of the monitored machinery.

DIN 45670/VDI 2059: German industrial standards related to vibration measurement and evaluation of rotating machinery, specifying methods for vibration amplitude calculation and assessment criteria.

ModBus TCP/IP: A widely used industrial communication protocol that enables data exchange between monitoring devices and control systems over Ethernet networks.

| Parameter | Specification |

|---|

| Board Type | PCB/EURO card (compliant with DIN 41494) |

| Dimensions (L × W × H) | 160.0 mm × 30.0 mm × 128.4 mm (6.300 in × 1.181 in × 5.055 in) |

| Weight | Net weight: approx. 320 g (0.705 lbs); Gross weight: approx. 450 g (0.992 lbs, including standard packaging) |

| Packaging Volume | approx. 2.5 dm³ (0.08 ft³) |

| Installation Requirements | 1 slot; A 19-inch rack can accommodate 14 modules |

Customers who purchased this product are also browsing the following products:

EPRO MMS6110 Dual Channel Shaft Vibration Monitor

EPRO PR 6423/000-000 8mm Eddy Current Displacement Transducer

Bently Nevada 1900/65A-01-00-01-00-00 Equipment Monitor

ABB PPC322BE01 HIEE300900R1 processor module

3005319639

3005319639