The Triconex 3720 is a TMR analog input module with a voltage range of 0 to 5VDC and a yellow color code. It can only be installed in Tricon v10.2 and higher version systems, and is also applicable to low-density systems that have been upgraded to v10.2.x or higher versions. For details, please refer to the specific appendix of the relevant guidelines. This module features high reliability and specific compatibility, and can stably perform analog signal input functions in industrial automation scenarios.

DATA SHEET

Core Configuration and Functions of 3720 Analog Input Module

Input Signals: 64 single-ended input signals with field-to-system isolation (minimum 800 VDC).

Signal Processing:

Each input channel receives variable voltage signals, converts them into digital values, and transmits them to the three main processors on demand. A mid-value selection algorithm is used to ensure the correctness of data in each scan.

A fault in a single channel will not affect other channels. The module can operate normally when a single fault exists and may continue to work under some multiple faults.

Resolution and Accuracy:

It can be configured as 12-bit (standard) or 14-bit (high) resolution in TriStation 1131.

In the range of 32°F to 140°F (0°C to 60°C), the accuracy is < 0.15% of Full Scale Range (FSR).

Over-range Capability: It provides 6% over-range measurement capability, with the input over-range measurement value ranging from 0 to 5.3 V. It has input overvoltage protection (150 VDC continuous, 115 VAC continuous).

Current Range: 0 to 20 mA (plus 6% over-range), which needs to be used with a 250Ω shunt resistor.

Diagnosis and Fault Handling of 3720 Analog Input Module

Continuous Diagnosis: Complete and continuous diagnosis is performed on each channel. Any diagnostic failure of a channel will activate the module's fault indicator, which in turn triggers the chassis alarm signal (the fault indicator points to a channel fault, not a module failure).

Mis-compare Readings: If the reading difference is ≥ 0.5% of full scale and lasts for 25 input samples, the probability of a fault increases. Rapidly or continuously changing inputs may prolong the fault detection time. If the difference between the input sample and the previous sample is > 0.25%, the readings will not be compared.

Hot-spare Feature: It supports online replacement of faulty modules without affecting system operation.

Physical and Electrical Specifications of 3720 Analog Input Module

Input Update Rate: 10 ms.

Resistance Parameters: Input resistance (load) is minimum 10 MΩ (DC), input resistance at power off is typically 140 kΩ (DC), and channel-to-channel isolation is typically 420 kΩ.

Normal Mode Rejection Ratio: -3 dB at 8Hz, -17 dB at 60Hz, -23 dB at 120Hz.

Logic Power: < 12 watts.

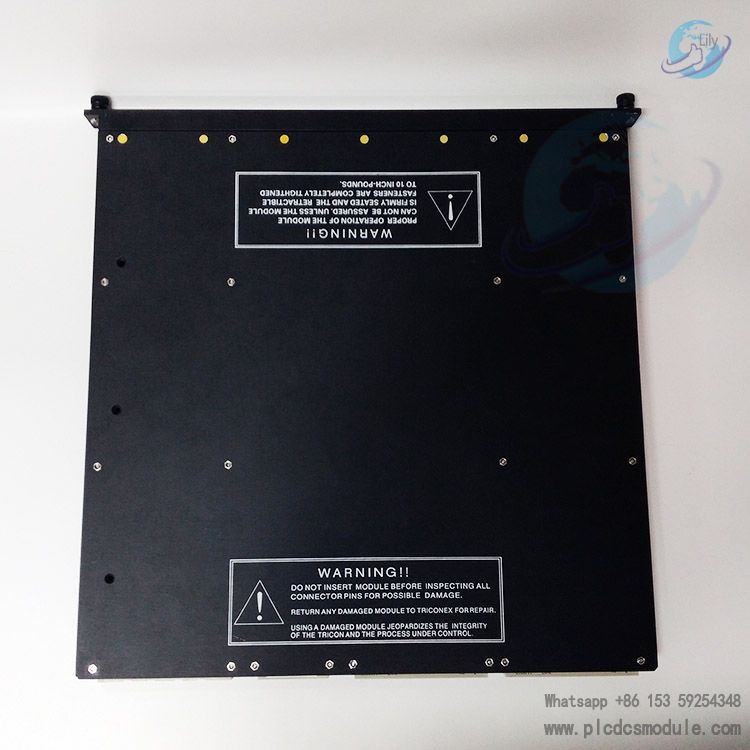

Status Indicators: The front panel has Pass (normal), Fault (fault), Active (active), and Field (field) indicators, marked with "ANALOG INPUT 3720" and "0-5 VDC".

Installation and Interface of 3720 Analog Input Module

A separate field termination assembly is required, which is connected to the Tricon controller backplane through a cable interface.

The module has a mechanical keying design to prevent improper installation in a configured chassis.

Oil and Gas Industry: It is used to monitor and control key processes, such as measuring parameters like temperature, pressure and flow, to realize process control and safety protection, ensuring the safe and stable operation of production operations. In the process of oil well exploitation, it can monitor the wellhead pressure and flow in real time, and once the parameters are abnormal, the system can respond quickly to ensure the safety of exploitation.

Chemical Industry: It is applied in process control in chemical plants. By collecting analog signals, it realizes precise control of chemical production processes, ensuring the safe, stable and efficient operation of the production process. For example, in the scenario of monitoring and controlling the temperature and pressure of reaction kettles, it can adjust the reaction conditions in time to avoid dangerous situations.

Power Industry: On the one hand, it is used in power plants to monitor the operating status of equipment such as generators and transformers, ensuring the safe operation of the power system; on the other hand, it is also applied in substations to ensure the stability of the power grid. For instance, it can monitor parameters such as voltage, current and temperature of generators to detect potential faults in advance.

Metallurgical Industry: It plays a role in process control in metallurgical enterprises such as steel plants, providing high-reliability control support for production processes to ensure the smooth progress of production. For example, it can monitor parameters such as furnace temperature and metal liquid level to control the production process.

Nuclear Industry: It is used in the control system of nuclear reactors to monitor various parameters of nuclear reactors, such as temperature, pressure and radiation level, ensuring the safe operation of nuclear power plants and preventing nuclear accidents.

Customers who purchased this product are also browsing the following products:

TRICONEX 3721C Analog Input Module

tricon3503E 24 Vac/Vdc Digital Input Module

GE SR760-P5-G5-S5-HI-A20-R-E Multilin 760 Feeder Management Relay

ABB CBI 20-P 3BDH000730R1 Binary Input Module

3005319639

3005319639