Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. ABB

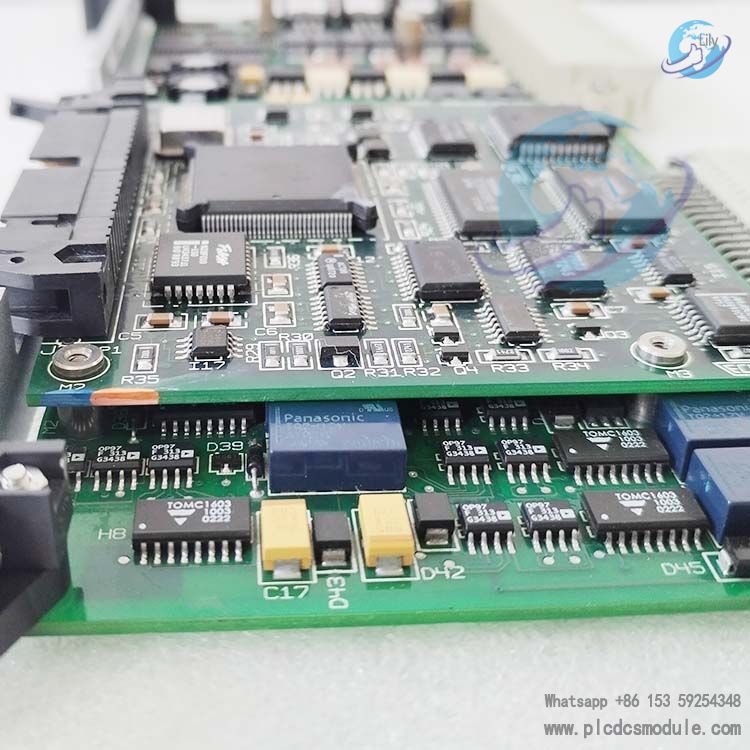

086329-004 is a high-performance

control card specifically designed for the ECS (Equipment Control Subsystem). It belongs to ABB small and medium-sized automation control hardware system, with its core positioning as the "core unit" for local equipment control and signal interaction.

It is compatible with ABB mainstream small and medium-sized control systems (such as AC500 PLC expansion systems and MicroSCADA monitoring substations), and can realize integrated functions including signal acquisition, logical operation, control command output, and equipment status monitoring. It is widely used in scenarios such as smart manufacturing standalone equipment, petrochemical auxiliary systems, power auxiliary control equipment, and water treatment devices.As an upgraded model of the ECS board in the ABB 086329 series, this control card retains the basic functions of the same-series model 086329-003 while optimizing signal processing accuracy and communication compatibility. It supports the integration of more third-party equipment and can be seamlessly integrated into the ABB automation ecosystem (e.g., paired with Control Builder configuration software and 800xA subsystems). It provides a highly reliable and flexible localized control solution for industrial sites, reducing dependence on upper-level main controllers and improving equipment response speed.

Product Advantages and Application Scenarios

(I) Core Advantages

Cost-Effective Control Solution for Small and Medium-Sized Equipment

Compared with the dedicated boards of ABB’s large-scale DCS systems, the 086329-003 ECS Board features lower cost. Meanwhile, it integrates signal acquisition, logic control, and communication functions, eliminating the need for additional expansion modules. It is suitable for the control needs of small and medium-sized equipment (such as standalone equipment and auxiliary production lines) and reduces users’ initial investment.

Convenient Configuration and Maintenance

It supports ABB’s universal configuration software (e.g., CODESYS, Control Builder). The graphical programming interface (supporting LD and FBD languages) lowers the programming threshold. The board panel is equipped with LED indicators for power, communication, and faults, allowing operation and maintenance personnel to intuitively determine the equipment status and reducing fault diagnosis time by 40%.

Flexible Expandability

It reserves 1-2 expansion interfaces, enabling the addition of digital/analog expansion modules (e.g., ABB DI801, AI801 modules) as needed. It can be expanded to a maximum of 32 DI channels, 16 DO channels, and 8 AI channels, meeting the needs of control scale upgrades without replacing the main board.

Core Functions and Technical Features

(I) Signal Processing and Control Capabilities

Compatibility with Multiple Signal Types

It supports common signal types in industrial sites, including Digital Input/Output (DI/DO) and Analog Input (AI):

Digital Signals: Compatible with 24VDC level signals, it can access discrete signals such as equipment start/stop status, limit switches, and fault alarms. It supports 8-16 channels of DI (input impedance ≥10kΩ) and 4-8 channels of DO (output contact capacity ≤2A/250VAC), meeting the on-off control requirements of small and medium-sized equipment.

Analog Signals: It supports the acquisition of 4-20mA current signals or 0-10V voltage signals (typically 4 channels of AI), enabling accurate collection of continuous parameters such as temperature, pressure, and flow feedback from sensors. The input accuracy error is ≤±0.2%, ensuring the accuracy of data acquisition.

Local Control Logic Execution

Equipped with a built-in basic logic operation unit, it allows the writing of simple control programs (e.g., start-stop interlocking, delay control, threshold alarm) via ABB’s dedicated configuration software (such as Control Builder). It can realize independent local control of equipment without relying on the upper-level main controller, reducing the system’s dependence on the main controller and improving control response speed (logic execution cycle ≤100ms).

Status Monitoring and Alarm

It monitors the operating status of itself and connected equipment in real time, such as power supply abnormalities, signal loss, and output overload. It triggers local LED indicator alarms (e.g., the red fault light stays on, the yellow alarm light flashes) and simultaneously uploads alarm information to the upper-level system through the communication interface, facilitating operation and maintenance personnel to detect and handle issues in a timely manner.

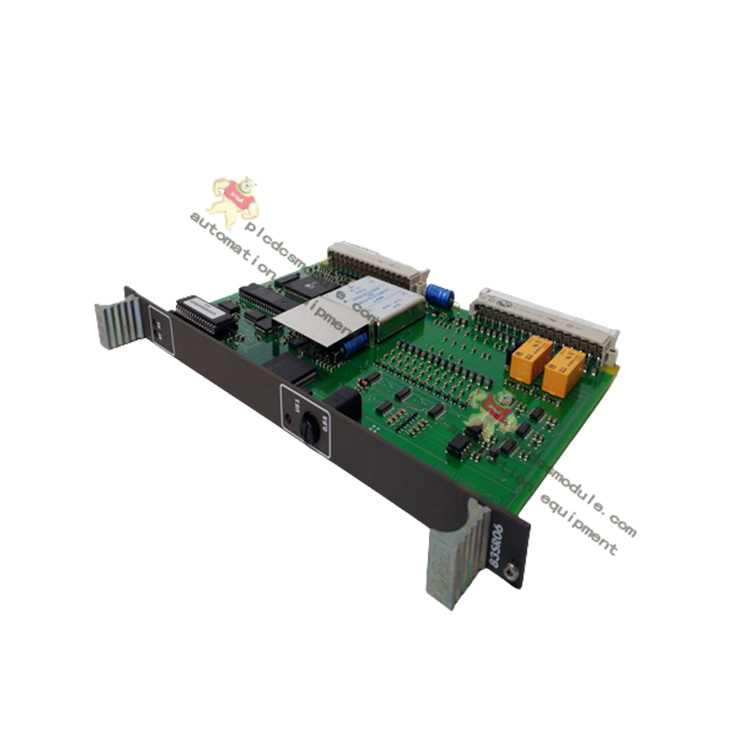

(II) Communication and Integration Capabilities

Standardized Communication Interfaces

It is equipped with 1 RS485 serial port (supporting Modbus RTU protocol) or an optional Ethernet interface (supporting Modbus TCP). The communication rate is configurable (up to 115200bps for RS485, up to 100Mbps for Ethernet). It can achieve data interaction with ABB main controllers (e.g., AC500 PLC, 800xA DCS substation) or third-party equipment (e.g., Human-Machine Interface (HMI), data logger), ensuring bidirectional transmission of control commands and status data.

System Compatibility

It is perfectly adapted to ABB’s industrial automation ecosystem and can be seamlessly integrated into ABB’s small and medium-sized control systems (e.g., AC500 series PLC expansion systems, MicroSCADA monitoring systems). It supports parameter configuration and program downloading via ABB’s standardized configuration tools, eliminating the need for additional driver development and reducing the difficulty of system integration.

(III) Reliability Design

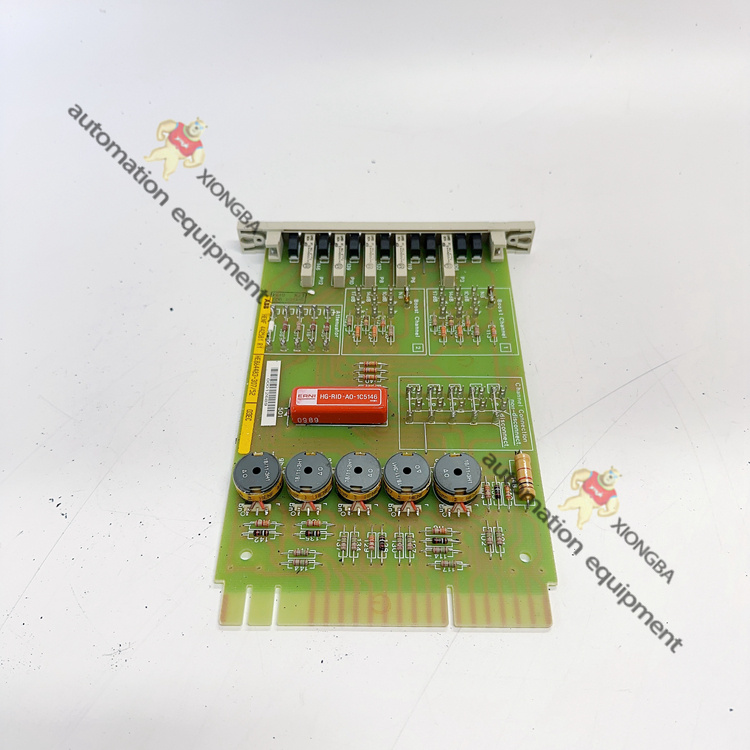

Industrial-Grade Hardware Selection

It adopts ABB-customized industrial-grade components, including high-temperature-resistant resistor-capacitor components (operating temperature range: -40℃~+85℃) and gold-plated connectors (contact resistance ≤10mΩ). All components undergo 100% high-temperature burn-in testing (85℃ for 24 hours) and Electromagnetic Compatibility (EMC) pre-testing. The Mean Time Between Failures (MTBF) is ≥50,000 hours, making it suitable for complex industrial on-site environments.

Basic Protection Functions

Overcurrent Protection: The digital output channel is equipped with a built-in overcurrent detection circuit. When the load current exceeds the rated value, the output is automatically cut off to protect the board and downstream equipment.

Power Reverse Polarity Protection: The power input terminal is equipped with a reverse polarity protection diode to prevent the board from being burned due to incorrect wiring.

Installation and Maintenance Precautions (In Compliance with ABB Industrial Equipment Specifications)

Pre-Installation Preparation

Confirm the compatibility between the board model (086329-003) and the control system it belongs to (e.g., ABB AC500 PLC requires firmware version V3.0 or above) to avoid functional abnormalities caused by version mismatch.

Inspect the board’s appearance: ensure connectors are not bent, components are not loose, and indicator lights are not damaged. Use a multimeter to measure the insulation resistance between power terminals (required to be ≥100MΩ) to confirm there are no electrical faults in the board.

Wiring Specifications

Power-Off Wiring: The system power must be cut off before wiring to prevent short circuits caused by live operations.

Classified Signal Routing: Power lines (24VDC), digital signal lines, and analog signal lines must be routed separately with a spacing of ≥20cm. Analog signal lines should use shielded twisted-pair cables (#22 AWG), with the shield grounded at one end (ground resistance ≤1Ω) to reduce interference.

Terminal Fastening: All wiring terminals must be tightened with a screwdriver (torque: 0.5-0.8N・m) to prevent poor contact caused by looseness.

Daily Maintenance

Regular Inspection: Check the status of LED indicators weekly (normal status: power light stays green, communication light flashes green, fault light is off). Clean dust on the board and terminals monthly (using a dry brush).

Parameter Monitoring: Read the board’s operating parameters (e.g., input signal value, output status, internal temperature) via configuration software quarterly to confirm there are no abnormal alarms.

Communication Testing: Test the communication link (e.g., Modbus communication timeout, data transmission accuracy rate) every six months to ensure stable communication with the upper-level system.

Fault Handling and Replacement

Fault Troubleshooting: If the fault light is on, first check the power voltage (whether it is within the range of 18-30VDC) and communication cables (whether they are loose or short-circuited). For software faults, restart the board or re-download the configuration program; for hardware faults (e.g., no power response), replace the board with the same model.

Replacement Process: Back up the board configuration parameters before replacement. After installing the new board, load the parameters, conduct a 1-hour no-load test after power-on, and then a 24-hour load test to confirm normal functionality.

Customers who purchased this product are also browsing the following products:ABB IOR810 P-HB-IOR-80010000 S800 I/O Gateway Module

ABB PNI800A Plant Network Interface Module

Schneider 140CPU67160S Modicon Safety controller

MOOG D136-001-007 servo controller

3005319639

3005319639