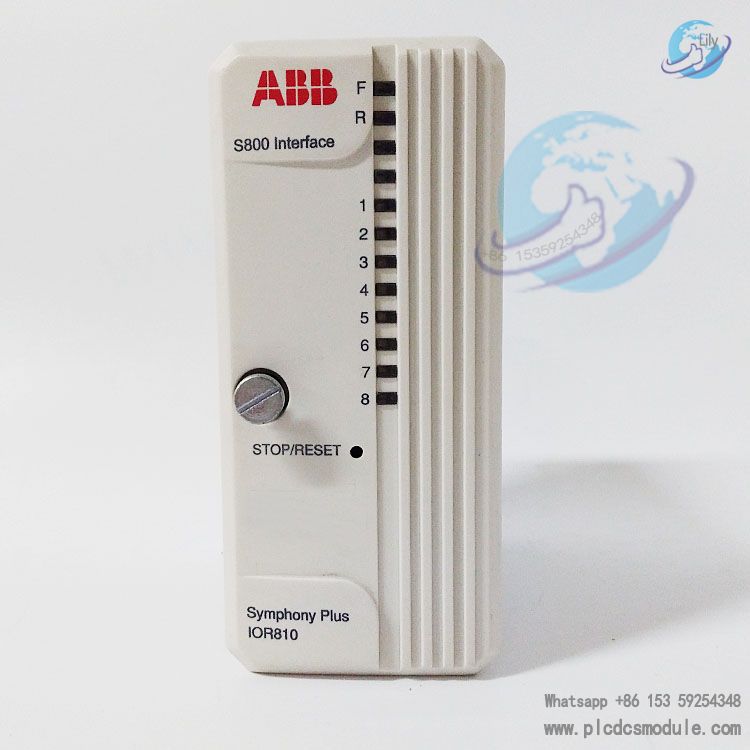

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. ABB IOR810P-HB-IOR-80010000 is a high-performance gateway module specifically designed to connect S800 I/O modules with the HN800 system. It plays a crucial role in industrial automation control systems: acting as a bridge between the S800 I/O system and the upper-level control system, it ensures efficient and stable data transmission. Widely used in industries such as energy, chemical engineering, and manufacturing, it lays a foundation for achieving accurate and reliable automated control.

DATA SHEET

ABB IOR810 P-HB-IOR-80010000.pdf

ABB IOR810 P-HB-IOR-80010000.pdf

Core Functions

(I) System Connection and Communication

Connecting S800 I/O Modules: This module can seamlessly connect to various modules in the S800 I/O series, including both digital input/output modules and analog acquisition and control modules. It enables stable connections to efficiently transmit signals from on-site equipment to the upper-level control system, while accurately delivering control commands to on-site actuators.

Adapting to the HN800 System: Specifically designed to work in synergy with the HN800 system, it can achieve high-speed data interaction with the HN800, ensuring smooth communication and real-time performance of the entire automated control system, and meeting the strict requirements for data processing speed in complex industrial scenarios.

Support for Industrial Standard Communication Protocols: It supports a variety of industrial standard communication protocols, such as the commonly used PROFIBUS. This ensures good compatibility with on-site equipment and control systems of different brands and types, facilitating users to build diversified and integrated automated networks.

(II) Data Processing and Conversion

Data Format Conversion: It can convert the format of raw data from S800 I/O modules into a format suitable for processing by the HN800 system, and vice versa. This function effectively solves the problem of data format incompatibility between different systems, improving the efficiency of data transmission and processing.

Data Caching and Preprocessing: It has a certain data caching capability to temporarily store data, avoiding data loss or transmission congestion caused by excessive instantaneous data traffic. At the same time, it can perform simple preprocessing on data, such as data filtering and error checking, to improve data quality and provide a reliable basis for subsequent precise control.

- Supply Voltage: Typically 24VDC, allowing voltage fluctuations within a certain range to adapt to different on-site power supply conditions and ensure the stable operation of the module.

- Operating Current: The maximum operating current is generally around 250mA. The specific value may vary slightly depending on different application scenarios and configurations. The low-power design helps reduce the overall energy consumption of the system.

- Communication Rate: Supports multiple communication rates, with a maximum of up to 12Mbps (under the PROFIBUS protocol). It can be flexibly selected according to the actual application scenarios and data transmission volume requirements, meeting the needs of automated control tasks with different real-time requirements.

- Data Transmission Delay: The data transmission delay is extremely low, ensuring that the status information of on-site equipment is timely fed back to the control system and control commands are quickly issued. This effectively improves the system response speed and enables precise control.

- Dimensions: Compact overall size, approximately 5.1cm × 10.2cm × 12.7cm (length × width × height), facilitating installation in control cabinets or equipment with limited space and saving installation space.

- Weight: Lightweight, approximately 0.2kg, making it easy to handle and install while reducing the load requirements on structures such as mounting brackets.

Power Plants:

In thermal power plants, it is used to connect the S800 I/O modules of equipment such as boilers and steam turbines to the HN800 control system. It collects key parameters (e.g., temperature, pressure, flow) in real time and issues control commands to on-site actuators, ensuring the stable operation and efficient power generation of power generation equipment.

In wind farms, it enables the connection between the S800 I/O modules of systems (such as wind turbine blade angle adjustment and pitch control systems) and the HN800 system, optimizing wind energy capture efficiency and improving power generation benefits.

Substations:

Used in substation automation systems to connect the S800 I/O modules of various intelligent devices to the HN800 system. It realizes the monitoring of power parameters, equipment status, and remote control, ensuring the safe and stable operation of the power system.

Petrochemicals:

In oil refining and chemical production facilities, it connects the S800 I/O modules on equipment (such as reactors and pipelines) to the HN800 system. It monitors and controls process parameters (e.g., temperature, pressure, liquid level) in real time, ensuring the safety and stability of the chemical production process and improving product quality and production efficiency.

Fine Chemicals:

Given the high requirement for control precision in fine chemical production, the IOR810 can accurately connect the S800 I/O modules to the HN800 system. It realizes precise control of key parameters (e.g., raw material ratio, reaction time), ensuring the high-quality production of fine chemical products.

Automotive Manufacturing:

On automobile production lines, it connects the S800 I/O modules of equipment (such as robots and automated assembly devices) to the HN800 system. It enables automated control and monitoring of the production process, improving the efficiency and quality consistency of automobile production and reducing labor costs.

Electronics Manufacturing:

In electronics manufacturing workshops, it connects the S800 I/O modules to the HN800 system, which is used to monitor and control the operating status of production equipment (e.g., chip mounters, reflow soldering equipment). This ensures the high-precision production and fast production rhythm of electronic products.

Customers who purchased this product are also browsing the following products:

GE FANUC IS200AEADH1AAA Control Circuit Board

GE DS200CTBAG1ADD Mark V Termination Board

Honeywell FW25-92 51401497-100 Dual Node Power Supply

KOLLMORGEN CB06561 PRD-B040SSLZ-62 Servo Drive

![]() ABB IOR810 P-HB-IOR-80010000.pdf

ABB IOR810 P-HB-IOR-80010000.pdf

3005319639

3005319639