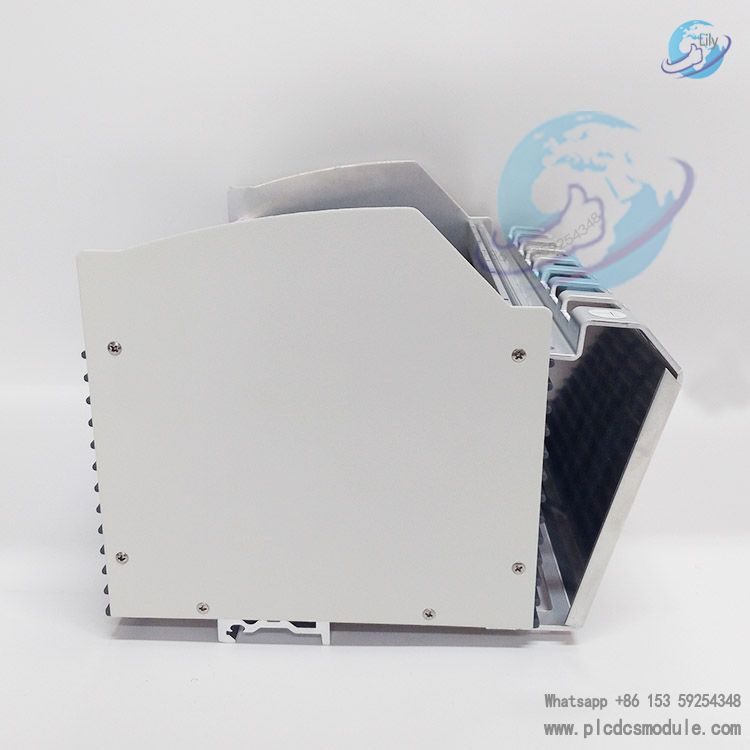

The PM803F 3BDH000530R1 Base Unit Module belongs to ABB AC 800M controller series, specifically designed for high-performance control applications in the industrial automation field. As the core computing and connection hub of the controller, this base unit module enables precise control of various equipment in industrial production processes, data acquisition, and real-time communication, providing industrial users with a stable and reliable automated control solution.

It adopts an advanced hardware architecture and software algorithms, featuring powerful processing capabilities and flexible expandability. It can be adapted to industrial automation systems of different scales, efficiently handling scenarios ranging from small-to-medium production line control to large-scale complex process industrial control. Meanwhile, this module complies with international industrial safety and electromagnetic compatibility standards, ensuring long-term stable operation in harsh industrial environments.

DATA SHEET

Performance Parameters

1.1 Core Processing Performance

Processor Model: High-performance 32-bit RISC processor

Computing Speed: Maximum instruction execution speed up to 100 MIPS (Millions of Instructions Per Second), supporting multi-task parallel processing to ensure fast response of complex control algorithms

Memory Configuration:

Program Memory (Flash): 8 MB, supporting permanent program storage with no data loss after power failure

Data Memory (RAM): 16 MB, meeting the requirements for temporary storage and fast access of large volumes of real-time data

Control Cycle: Minimum control cycle as low as 1 ms, enabling accurate capture of subtle changes in industrial production processes and realization of high-precision control

1.2 Communication Interfaces

Ethernet Interfaces: 2 x 10/100 Mbps auto-negotiation Ethernet ports (RJ45 interface), supporting mainstream network protocols such as TCP/IP and UDP. It enables high-speed data interaction with upper computers, HMIs (Human-Machine Interfaces), and other automation equipment

Fieldbus Interface: 1 reserved Profibus-DP master/slave interface (optional), supporting seamless connection with Profibus bus devices (e.g., frequency converters, sensors, actuators) with a maximum communication rate of 12 Mbps

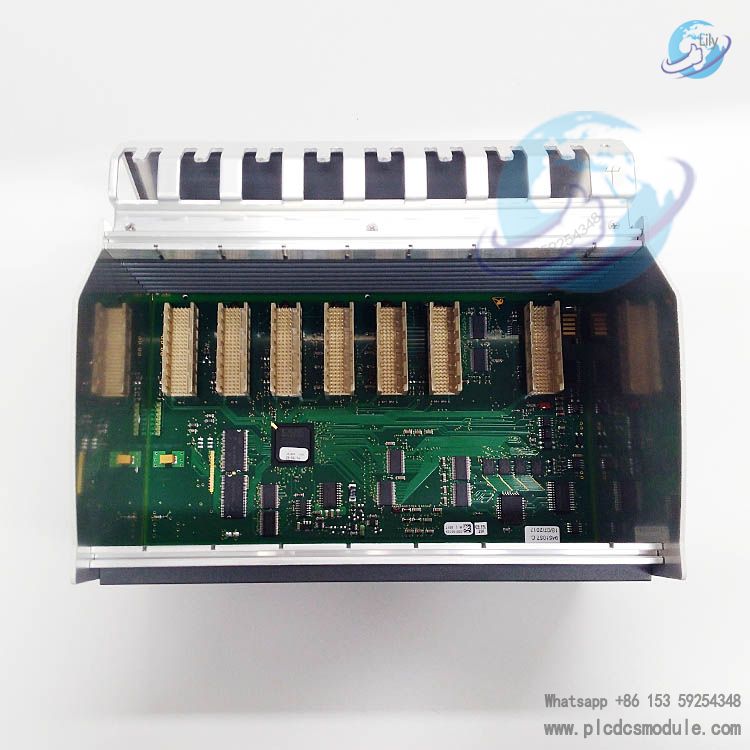

Internal Bus Interface: 1 AC 800M internal bus interface, used for connecting expansion components of the AC 800M series (such as I/O modules and communication modules) to achieve high-speed data transmission between modules (transmission rate up to 1 Gbps)

1.3 Power Supply and Power Consumption

Supply Voltage: DC 24 V (allowable fluctuation range: DC 19.2 V - 28.8 V), complying with industrial-grade power supply standards and adapting to power supply environments of different industrial sites

Typical Power Consumption: Approximately 5 W during normal operation, and less than 1 W in standby mode. It features low power consumption to reduce energy consumption of the industrial system

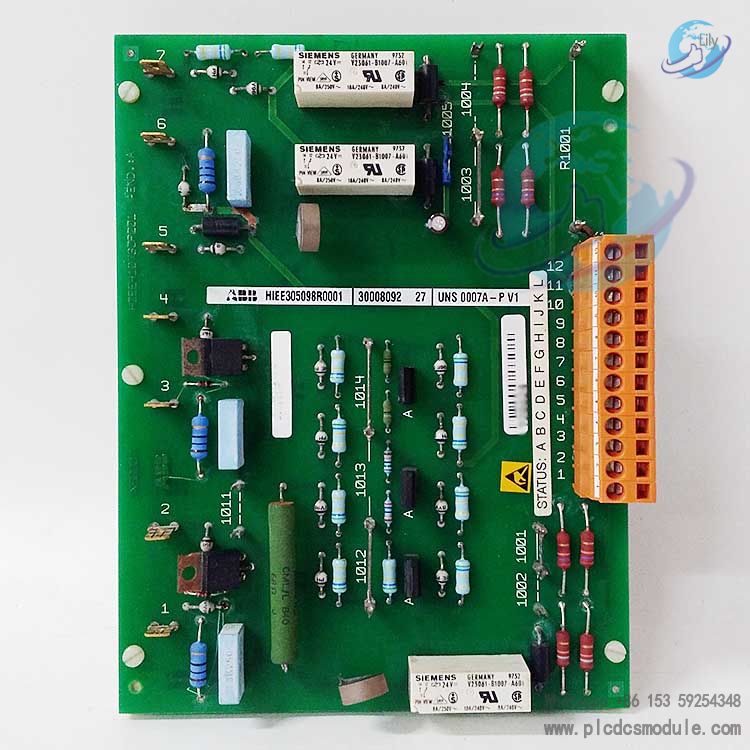

Power Protection: Equipped with Over-Voltage Protection (OVP), Over-Current Protection (OCP), and short-circuit protection functions, effectively preventing damage to the module caused by power supply abnormalities

1.4 Environmental Adaptability

Operating Temperature: -25 °C - +60 °C, enabling stable operation in high and low-temperature industrial environments

Storage Temperature: -40 °C - +85 °C, facilitating product transportation and long-term storage

Relative Humidity: 5% - 95% (non-condensing), adapting to humid industrial site environments

Protection Class: IP20 (when panel-mounted), effectively preventing dust and foreign objects from entering the interior of the module

Electromagnetic Compatibility (EMC): Compliant with IEC 61000-6-2 (Immunity for Industrial Environments) and IEC 61000-6-4 (Emission for Industrial Environments) standards, maintaining stable performance even in strong electromagnetic interference environments

Advantages and Features

2.1 High Performance and High Reliability

Adopting a high-performance RISC processor and industrial-grade components, the module ensures stability and reliability during long-term continuous operation, with a Mean Time Between Failures (MTBF) of over 100,000 hours.

Equipped with a comprehensive fault diagnosis function, it can real-time monitor the module’s power supply status, communication status, processor operation status, etc. In case of a fault, it immediately notifies the user via an alarm signal, facilitating quick troubleshooting and maintenance.

2.2 Flexible Expandability

Supports seamless connection with various I/O modules (such as digital input/output modules, analog input/output modules, special function modules, etc.) and communication modules (such as Modbus modules, EtherNet/IP modules, etc.) of the ABB AC 800M series. Users can flexibly configure the system scale according to actual control requirements.

The internal bus interface adopts high-speed data transmission technology, so there is no need to worry about data transmission bottlenecks when expanding modules, ensuring the efficient operation of the entire control system.

2.3 Convenient Programming and Debugging

Compatible with ABB Control Builder M programming software, which supports multiple international standard programming languages including Function Block Diagram (FBD), Ladder Diagram (LD), and Structured Text (ST). Users can choose a suitable language for control program development based on their own programming habits.

The software has a built-in rich function library and template programs, covering common control algorithms in the industrial control field (such as PID control, logic control, sequence control, etc.), which greatly shortens the user’s program development cycle.

Supports online programming and debugging functions. Users can modify control programs and monitor variable status during the normal operation of the module without stopping the production process, reducing the impact of debugging on production.

2.4 Powerful Communication Capabilities

Equipped with multiple types of communication interfaces, it supports mainstream industrial communication protocols such as Ethernet and Profibus-DP. It can achieve interconnection and intercommunication with automation equipment of different brands and types (such as PLCs, frequency converters, sensors, HMIs, SCADA systems, etc.), building a flexible industrial communication network.

Supports network redundancy function. When a fault occurs in Ethernet or fieldbus, it can automatically switch to the backup communication link, ensuring the continuity of data transmission and improving the reliability of the industrial system.

2.5 Compliance with International Standards and Safety Norms

The product design and manufacturing comply with multiple international standards such as IEC (International Electrotechnical Commission), UL (Underwriters Laboratories), and CE (Conformité Européenne), enabling it to be sold and applied worldwide.

Application Fields

With its outstanding performance and stability, the ABB PM803F 3BDH000530R1 Base Unit Module is widely used in multiple industrial fields, including the following:

3.1 Petrochemical Industry

In production processes such as petroleum refining and chemical synthesis, this module can serve as a core controller to realize real-time monitoring and precise control of key process parameters (e.g., temperature, pressure, and flow rate of reactors). It ensures the safety and stability of the production process while improving product quality and production efficiency. For instance, in ethylene production plants, the PM803F module can control parameters like raw material feed rate and reaction temperature, preventing production accidents caused by parameter fluctuations.

3.2 Power Industry

It is suitable for automated control systems in thermal power plants, hydropower plants, and substations. In thermal power plants, it can be used in key links such as boiler combustion control and steam turbine speed control to achieve automatic regulation of the power generation process and improve power generation efficiency. In substations, it can cooperate with relay protection equipment and measurement & control equipment to realize real-time monitoring of power grid operation status and rapid fault handling, ensuring the stable operation of the power grid.

3.3 Metallurgical Industry

In the smelting process of iron and steel, non-ferrous metals, this module can control parameters such as the temperature, liquid level, and composition of smelting furnaces, ensuring the smelting process meets process requirements. For example, in the converter steelmaking process of iron and steel plants, the PM803F module can automatically adjust the oxygen supply volume, scrap steel addition amount, etc., according to the steelmaking process curve. This improves molten steel quality and smelting efficiency while reducing energy consumption and production costs.

3.4 Manufacturing Industry

It is widely used in automated production line control for discrete manufacturing industries such as automobile manufacturing, mechanical processing, and electronic equipment production. In automobile welding production lines, it can control parameters like robot welding trajectory, welding current, and welding time to ensure the consistency of welding quality. In mechanical processing production lines, it can realize control of machine tool processing accuracy and adjustment of production rhythm, improving the automation level and production efficiency of the production line.

3.5 Water Treatment Industry

It is used in automated control systems of waterworks and sewage treatment plants to realize real-time monitoring of water quality indicators (e.g., pH value, turbidity, dissolved oxygen) and automatic control of treatment processes. For example, in the aeration tank control of sewage treatment plants, the PM803F module can automatically adjust the operating power of aeration equipment according to the dissolved oxygen concentration, optimizing sewage treatment effects and reducing operating costs.

Frequently Asked Questions

Q1: The power indicator (PWR) of the ABB PM803F 3BDH000530R1 module does not light up after power-on. How to troubleshoot this issue?

A: First, check the DC 24V power supply. Use a multimeter to measure the voltage at the power terminals ("DC 24V" and "GND") and confirm if it is within the normal range of 19.2V-28.8V. If the voltage is abnormal, the power supply circuit needs to be repaired. Second, inspect the power wiring to ensure that the wires are firmly connected to the terminals without looseness or oxidation, and that the positive and negative poles are not reversed. Finally, if both the voltage and wiring are normal, there may be an internal fault in the module, and you need to contact ABB official after-sales service for testing and maintenance.

Q2: When using Control Builder M software, communication cannot be established with the ABB PM803F 3BDH000530R1 module. What may be the reasons?

A: First, check the Ethernet physical connection. Confirm that the RJ45 connectors at both ends of the Cat5e or higher-grade network cable are properly crimped, and check if the indicator lights of the module’s Ethernet port and the switch/upper computer port are flashing normally (a steady green light or regular flashing indicates a normal connection). Second, verify the IP address configuration to ensure that the module’s IP address and the upper computer’s IP address are in the same network segment without IP conflict. Finally, check the software version to confirm that the Control Builder M version is compatible with the module’s firmware version (it is recommended to use the matching version recommended on the ABB official website). If the versions are incompatible, the software needs to be upgraded or downgraded.

Q3: The ABB PM803F 3BDH000530R1 module suddenly fails to respond to control commands during operation. How to handle this?

A: First, check if the module’s fault indicator (such as the "ERR" light) is on. If it is on, you can read the fault code through the Control Builder M software and troubleshoot the problem based on the code (e.g., internal bus fault, abnormal I/O module connection, etc.). Second, inspect the internal bus connection, confirm that the internal bus cable plug between the module and the extended I/O module is not loose, then re-plug the cable and restart the module. If the fault persists, you need to pause production, back up the control program, and then restart the module. If the module returns to normal after restart, record the fault time and scenario to facilitate subsequent troubleshooting of potential issues. If the restart is ineffective, contact ABB technical support.

Customers who purchased this product are also browsing the following products:

ABB GD9924BE V2 HIEE401091R0002 High-voltage control board

ABB 134177-001 online motherboard module

PROSOFT MVI56-MCM Modbus Communication Module

BENTLY NEVADA 106M1079-01 3500/15 Universal AC Power Supply

3005319639

3005319639