Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The ABB NGC8206 is a portable gas chromatograph designed specifically for natural gas custody transfer, metering, and analysis, while also featuring on-site installation capabilities. It combines simplicity, low-cost installation, and excellent performance, redefining the standards for natural gas calorific value determination. Compact in size, the NGC8206 occupies a space equivalent to most multivariable transmitters. However, it can realize on-site gas analysis and calorific value calculation in scenarios where traditional chromatograph technology is not applicable or the cost is too high, such as when the gas volume is insufficient to justify a continuous online solution, or when the overall cost and maintenance expenses of gas samplers are excessively high. It is suitable for fields like natural gas custody transfer, production monitoring, and the energy market.

Its fast analysis cycle and automatic setting function greatly simplify the installation and maintenance processes. Equipped with a built-in 32-bit digital controller, dual electronic carrier gas pressure regulators, oven-mounted sensors, and low-noise electronic components, it ensures unparalleled sensitivity, with calibration intervals extending up to several months. Its core functions include real-time determination of natural gas components, calorific value, and other key parameters, as well as support for remote data transmission and automatic calibration. Additionally, when spot sampling is required, the device is already powered on and operating stably, eliminating waiting time at the measurement site. Overall, it has a compact structure, is reasonably priced, and is easy to operate and maintain.

DATA SHEET

ABB NGC8206 user manual.pdf

ABB NGC8206 user manual.pdf

ABB NGC8206 data sheet.pdf

ABB NGC8206 data sheet.pdf

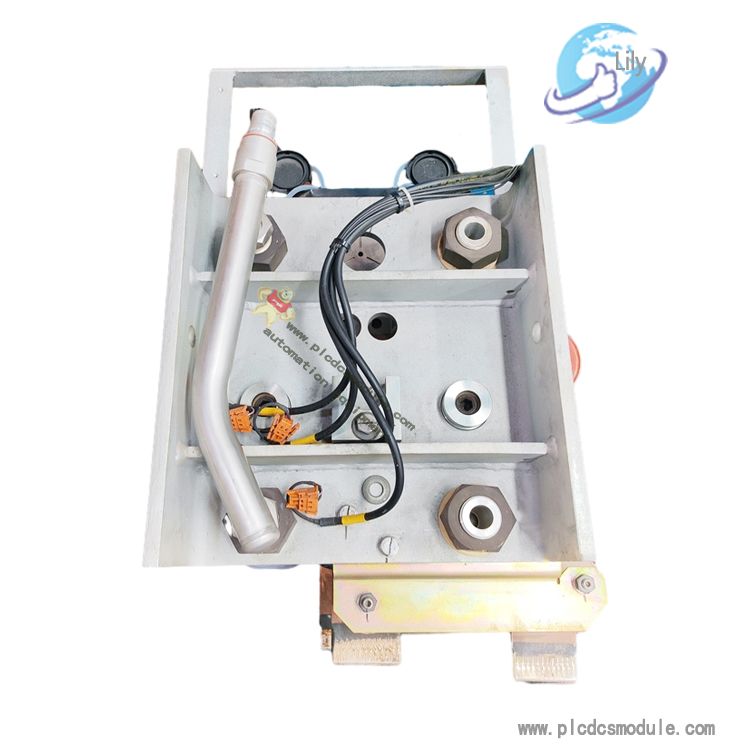

Compact Design: The NGC8206 features a compact design for easy installation and maintenance. It measures 6.75 inches in diameter x 16 inches in length x 9.00 inches in height (17.1 cm x 40.6 cm x 22.9 cm) and weighs approximately 28 pounds (12.7 kg).

Technical Parameters

Core Functions and Analytical Capabilities

The NGC8206 utilizes mature chromatographic technology to analyze samples, capable of determining the mole percentages of the following components:

"Air" (including N₂, Ar, CO, and O₂, but excluding CO₂)

C₁, CO₂, C₃, iC₄, nC₄, NeOC5, iC5, nC₅, C₆+

Through the backflushing of chromatographic columns using process chromatographic technology, the device can measure the C₆+ peak. Users can also input comprehensive laboratory analysis results, which reflect the splitting or proportion of components from C₆ to C₁₀, and this proportion can be used for subsequent analysis and energy calculation.

Based on the analysis results, a number of important parameters can be calculated, including:

- Gas compression factor in accordance with AGA 8 standards

- Actual relative density (specific gravity)

- British Thermal Unit/Calorific Value (Btu/CV Value)

- Gallons per thousand cubic feet (GPM)

- Wobbe Index

- Methane Number

Optional calculation items include: AGA 10 sound velocity, hydrocarbon dew point.

The NGC8206 is a weatherproof device designed for "on-pipe" installation, close to the sampling point. It can be installed outdoors within a temperature range of 0°F to 130°F (–18°C to 55°C); with the low-temperature option, it can operate reliably within a temperature range of –20°F to 130°F (–29°C to 55°C). It is suitable for pipes with diameters ranging from 2" to 12" and can also be configured with a pole-mount option. If the environmental conditions are below the dew point of the sampled gas or the operating specifications of the device, a cold-weather enclosure can be selected.

The integrated flow path selector of the NGC8206 allows sampling of up to 4 different natural gas streams, among which a maximum of 2 sample streams can be designated as "calibration/verification samples". Optional sample handling modules can be used for natural gas streams requiring additional filtration, as well as "fast flow loops" to reduce sample transmission lag time.

The function setting and operation of the NGC8206 are completed through a graphical user interface software package called PCCU 32, which is provided with each device and runs on a laptop computer under the Microsoft Windows environment. Combined with the software specially designed for the NGC8206, Windows utilities provide powerful tools for operation, diagnosis, and downstream data processing. The computer can be directly connected to the NGC8206 via RS232, USB, or Ethernet, or indirectly connected through remote telemetry (telephone modem, radio, mobile phone, satellite, etc.). Users can perform settings, operations, data collection, and monitoring through buttons, drop-down boxes, wizards, and dialog boxes.

In addition, the device is equipped with an optional ¼ VGA interactive display, through which users can obtain basic analysis data, and most "operator" functions can be completed from the front panel display without a laptop. The "Run-Hold-Calibrate" functions can be executed through the magnet interface on the explosion-proof glass of the display.

Product Features

Modular Design

- Modular Software — Application-based plug-in software modules

- Manifold module (internal tubing has now been replaced by manifold)

- The analytical part includes a flow path selection solenoid valve, pressure regulation, 32-bit digital detector electronics, and a dual-column chromatograph, all integrated into a replaceable module

- 32-bit digital, low-power control electronics with Windows CE (inside the GC unit)

- Microsoft Windows-based human-machine interface software (PCCU 32)

- Lithium battery-backed RAM

- Two remote serial digital communication ports; one local port

- Comprehensive diagnostics and wizards for users

- Three-level security user access control

- Audit-grade historical data; with date and time stamps

Automatic Start-up Cycle

The automatic start-up cycle automatically performs the following operations:

- Stabilize the oven temperature

- Confirm module functions

- Set valve operation time

- Locate natural gas components

- Set carrier gas pressure

- Mark natural gas components

- Verification / calibration

- Return to pipeline flow

- Operate alarms and events, with time and data recorded in the log

Other Features

- Memory: Up to 2.052 GB

- Detector — Constant temperature, glass-encapsulated thermistor beads, suitable for harsh environments, with a long service life, and will not burn out when carrier gas is lost

- Dual 10-port valves, no moving metal parts

- Low utility consumption — Low power consumption, low carrier gas usage, no instrument air required

- Automatic calibration and diagnostics on demand or scheduled

- Calibration options: Exponential, linear

Optional Configurations

- Sample handling system

- Onboard digital ¼ VGA display with multi-screen access

- USB (host and client) and Ethernet ports

- Calculation packages (such as V.O.S., HCDP, etc.)

- SD memory card (maximum 2 GB)

- Feedthrough heater

- C7 +, C9 + analysis

- Optional: AI/DI, AO/DO available upon customer request

- Optional: 24-hour temperature test

Maintenance-related

The NGC8206 is designed from the outset to be maintained by personnel with little or no knowledge of gas chromatographs. Both hardware and software achieve low maintenance requirements through easily replaceable electromechanical modules, which include:

- NGC terminal panel

- NGC analysis module, an easily detachable chromatograph sub-assembly containing: NGC manifold, flow path selection solenoid valve, GC module, dual electronic carrier gas pressure regulating valve, chromatograph pilot valve, NGC analysis processor

- NGC feedthrough (with optional heater)

- Sample handling module (SCM)

- NGC controller (32-bit processor)

- NGC ¼ VGA display (optional)

Other maintenance support functions:

Historical Data

The NGC8206 is designed to retain historical data, which can be used for custody transfer needs, verifying transmitter operation over time, and providing limited data backup for the reliability of communication links. Users can configure the period for which the NGC8206 retains data through the operator interface.

The default memory configuration provides the most recent 480 analysis cycles, including:

- Normalized components

- Non-normalized components

- Ideal Btu/CV

- Actual Btu (wet and dry)/CV (superior and inferior)

- Relative density (specific gravity)

- Density

- GPM

- Wobbe Index

- Alarms

The flow averages (by default) are analyses from the most recent 840 hours, the most recent 35 days, and the most recent month. The operating parameters (diagnostic reports) for the most recent 480 cycles include:

- Selected peak times

- Selected peak areas

- Ideal Btu/CV

- Carrier gas regulator pressure

- Oven temperature

- Ambient temperature

- Sample pressure

- Detector noise value

- Detector balance value

The audit log (by default) includes:

- The most recent 480 alarms

- The most recent 480 events

The data retained by the NGC8206 can be collected via a remote communication link or the local operator interface PCCU 32 on a laptop.

The default memory configuration will provide the above-mentioned data storage, and users can reallocate the available memory.

Available Accessories

- 120/240 V AC to 12 V DC GP and Exp power supplies

- Pole-mount or pipe-mount kits

- Cold weather enclosures (also available in pipe-mount configurations)

- Cold weather insulation sleeves (future)

- Modular sample system regulator options for: non-pipeline quality natural gas samples, sample transmission lag time requirements

- Probes: temperature-compensated fixed type, temperature-compensated retractable type, liquid-repellent type, electrically heated retractable type

- Regulators (carrier gas and calibration mixtures)

- Start-up calibration/verification gas samples (±2% accuracy)

- Carrier gas: 99.995% pure helium (chromatographic grade)

- Hydrogen carrier gas (optional)

- SD memory cards

- Export crating

- Toolkits

- Welker liquid shutoff valves

- Various maintenance kits

- Customer Factory Acceptance Test (FAT)

Customers who purchased this product are also browsing the following products:

ABB NTDI01 Digital I/O Termination Unit Module

ABB XUD194A 3BHC018137R0001 AC 800PEC MODULE

ABB SA9923A-E HIEE450964R0001 High-voltage control board

GE IS210MACCH1AKH Mark VI High-performance controller module

3005319639

3005319639