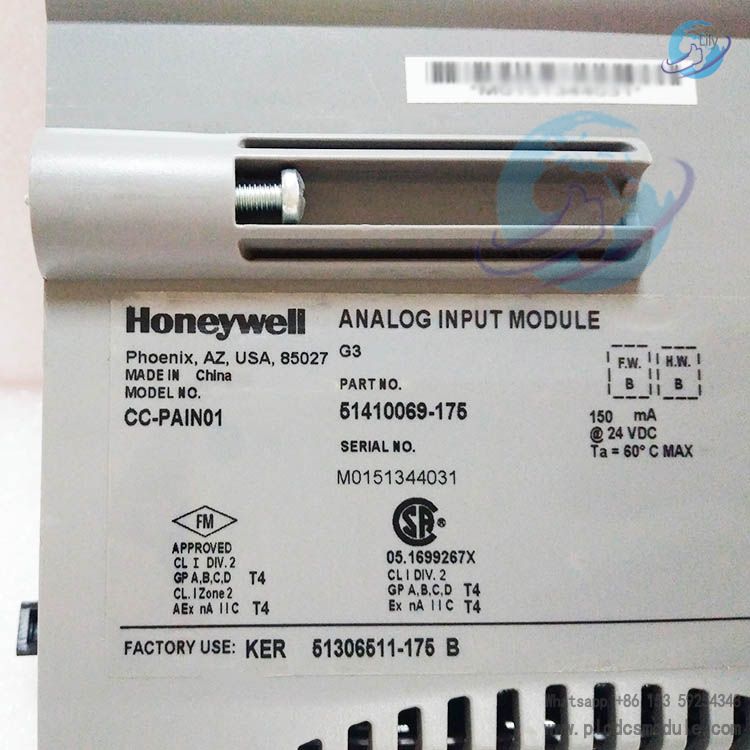

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. CC-PAIN01 51410069-175 is a high-performance advanced

analog input module in the Honeywell Experion Series-C I/O family. Its core function is to receive high-level current input signals from sensors or transmitters, providing accurate process data acquisition support for industrial automation control systems.

Relying on the innovative design concept of the Series-C I/O family, this module does not require an independent chassis to house electronic components. It can be directly plugged into the Input Output Termination Assembly (IOTA), realizing the integrated integration of the module and on-site wiring. This significantly simplifies the installation process and saves space in the control cabinet.

As a module dedicated to current signal acquisition, it only supports 4-20mA current input (via a 200Ω resistor) and is compatible with 2-wire or self-powered transmitters. Additionally, it features non-incendive field power supply capability, meeting the non-incendive power rating requirements for Class 1, Div 2 hazardous areas. It can provide safe power supply for on-site equipment without the need for additional external 编组 (marshaling).

Meanwhile, the module is equipped with comprehensive self-diagnostic functions and channel-level current limiting protection circuits. It can monitor signal abnormalities and its own faults in real time, preventing system shutdown caused by on-site wiring short circuits or equipment failures. This makes it a stable and reliable data acquisition solution for industries such as petrochemicals, electric power, and metallurgy, where extremely high requirements are placed on production continuity.

It holds Class 1, Div 2 certification for non-incendive field power supply. The independent channel current-limiting protection circuit prevents module damage caused by on-site wiring short circuits, eliminating the need for additional fuses and reducing maintenance costs. It supports redundant configuration, and critical channel backup is achieved through the CC-TAIN11 redundant IOTA, enhancing the system's fault resistance.

Equipped with 16-bit A/D resolution and high precision of ±0.075% full scale, it can capture subtle changes in 4-20mA signals. With a 70dB common mode rejection ratio (CMRR) and -60dB crosstalk between channels, it can resist electromagnetic interference in industrial sites (such as interference generated by motors and frequency converters), ensuring stable and accurate signal acquisition.

Adopting the iconic "Module-IOTA" integrated structure of the Series-C I/O, the module is directly plugged into the IOTA without the need for an independent chassis. The 6-inch non-redundant IOTA (CC-TAIN01) only occupies 152mm of installation space, saving more than 40% of control cabinet space compared to traditional discrete modules, making it suitable for high-density installation scenarios.

Built-in comprehensive self-diagnostic functions can real-time monitor faults such as channel open circuits and signal over-ranges, and feed back fault information through the system. The module and IOTA are connected in a plug-and-play manner; no wire removal is required during replacement, and the module can be removed by simply loosening the fixing screws, significantly shortening maintenance time.

Field power is uniformly supplied through the IOTA, eliminating the need for additional procurement of marshaling power supplies. The non-differential input design focuses on core current signal acquisition needs, avoiding cost increases caused by redundant functions. At the same time, the 16-channel design can reduce the investment in single-channel equipment and lower the overall project cost.

It is suitable for pressure and liquid level monitoring scenarios in crude oil extraction, oil refining equipment, and chemical reactors. The module can collect 4-20mA signals output by pressure transmitters and liquid level transmitters, and feed back key parameters such as pressure inside the reactor and liquid level in storage tanks in real time. Its non-incendive power supply design is compatible with hazardous areas (Class 1, Div 2) in oil refineries and chemical plants, avoiding safety accidents caused by electric sparks and ensuring the safety and controllability of the production process.

It is used for signal acquisition of boiler feedwater pressure in thermal power plants, turbine lubricating oil pressure, and turbine guide vane opening sensors in hydropower plants. The module’s 16-channel design can monitor multiple key measuring points simultaneously, and its fast input scan rate of 50ms can promptly capture parameter fluctuations. Cooperating with the redundant IOTA (CC-TAIN11), it can realize dual backup of important signals, prevent unit shutdown due to data acquisition interruption, and ensure stable power supply.

It is compatible with pressure transmitters in the hydraulic system of rolling mills and mold level transmitters in continuous casting machines, collecting 4-20mA current signals to monitor parameters such as steel rolling pressure and mold liquid level in real time. Its low crosstalk characteristic of -60dB between channels enables stable operation in the strong electromagnetic interference environment of metallurgical workshops, avoiding parameter misjudgment caused by signal interference and improving the quality of steel production.

It is used for signal acquisition of parameters such as water turbidity in waterworks and dissolved oxygen in sewage treatment plants. The module can directly supply power to on-site transmitters without an external marshaling power supply, simplifying the wiring of the waterworks control cabinet. At the same time, its high precision of ±0.075% full scale can accurately feed back water quality indicators, helping waterworks realize automated chemical dosing and water quality adjustment to meet environmental protection and discharge requirements.

Q1: Can the CC-PAIN01 module collect voltage signals (e.g., 0-10V DC)? Why?

A1: No, it cannot. The CC-PAIN01 is a high-level analog input module specifically designed for current signals. In terms of hardware, it only supports 4-20mA DC current input (via a 200Ω resistor), has no voltage signal acquisition circuit, and does not support differential input functionality. If voltage signal acquisition is required, modules such as CC-PAIH02 or CC-PAIX02 in the Series-C I/O family (which support 0-10V and 1-5V voltage inputs) should be selected. Forcing voltage signals into the CC-PAIN01 may cause module damage.

Q2: When installing a redundant configuration, which IOTA should be matched with the CC-PAIN01? Is manual intervention required for redundant switching?

A2: To achieve redundancy, the CC-PAIN01 must be matched with the redundant IOTA model CC-TAIN11 (12 inches / 304mm), while the non-redundant configuration uses the CC-TAIN01 (6 inches / 152mm). No manual intervention is needed for redundant switching: when the primary module malfunctions (e.g., abnormal signal acquisition, module power failure), the system will automatically detect the issue and switch to the standby module. There is no signal interruption during the switching gap (refer to the Series-C I/O redundancy design logic), ensuring uninterrupted acquisition of critical parameters.

Q3: If a channel of the CC-PAIN01 module displays "signal over-range", what are the possible causes? How to troubleshoot?

A3: The possible causes and troubleshooting steps are as follows:

- Transmitter failure: Disconnect the signal wire of the problematic channel and use a multimeter to measure the transmitter's output current. If the current is outside the 4-20mA range (e.g., <3.8mA or >20.2mA), the transmitter is faulty and needs to be calibrated or replaced.

- Signal wire interference/short circuit: Check if the signal wire is routed in parallel with high-voltage cables or if there is damage causing a short circuit (e.g., short-circuited "+" and "-" poles). Reorganize the cables or replace the damaged wires.

- Module channel failure: Connect the signal wire of a normal transmitter to the faulty channel. If the "over-range" prompt still appears, the module channel is damaged and the module needs to be replaced; if the signal returns to normal, the issue lies with the original transmitter or signal wire.

Q4: What is the maximum signal wire length supported by the CC-PAIN01? What happens if this length is exceeded? How to resolve the issue?

A4: According to the general specifications of the Series-C I/O, the maximum signal wire length supported by the CC-PAIN01 is 1000 feet (approximately 305 meters), and it is recommended to use 16AWG (2.5mm²) multi-strand copper-core wires. Exceeding the maximum length will cause signal attenuation, which manifests as the collected value being lower than the actual output value of the transmitter (e.g., the transmitter outputs 20mA, but the module only collects 19.5mA), affecting measurement accuracy.

Solutions: ① Shorten the signal wire length to within 1000 feet; ② Use wires with a larger diameter (e.g., 14AWG/4mm²) to reduce line resistance; ③ Add a signal repeater in the middle of the signal wire to compensate for signal attenuation.

3005319639

3005319639