Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The MOTOROLA

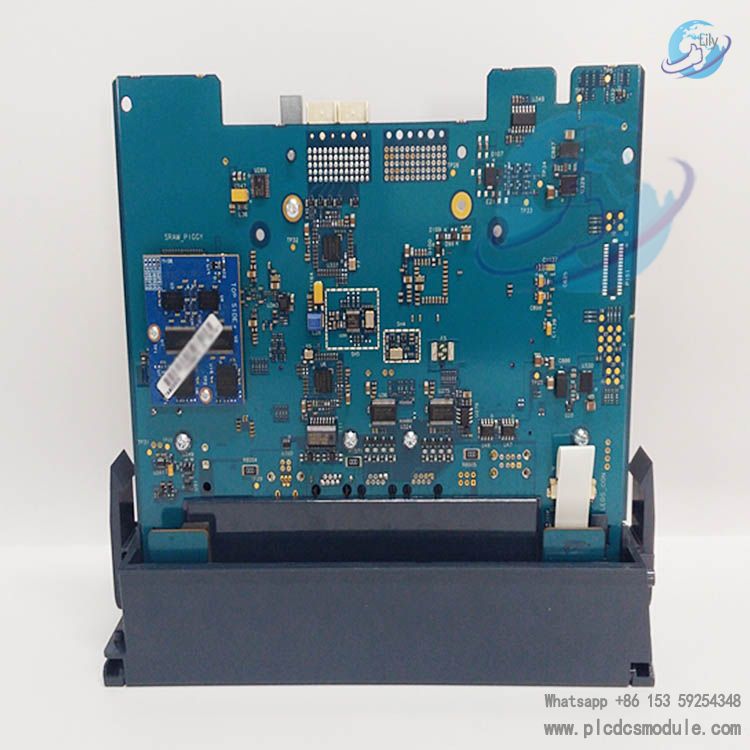

FLN4234A CPU3680 programmable logic controller (

PLC) module undertakes the important task of centrally processing and calculating various types of data within the system. Meanwhile, it also conducts strict monitoring, control and analysis to ensure the safe and stable operation of the entire control system.

Integrating advanced technical concepts, this module is manufactured using high-performance CMOS technology, featuring excellent computing speed and low power consumption, thus providing reliable support for industrial applications. In the system architecture, it plays a crucial role as a central processing unit—just like the human brain controlling the body, it coordinates the orderly operation of the entire automated system.

Performance Parameters

- Microprocessor: It is highly likely equipped with the Freescale PowerPC II MPC 8720 microprocessor. This is a powerful 32-bit chip that boasts outstanding computing capabilities and expanded communication functions. It can process various complex instructions quickly and accurately, laying a solid foundation for the efficient operation of the module.

- Memory Configuration: It is usually furnished with 16MB of flash memory, among which 3MB is freely available for users to store key programs and important data. It is paired with 32MB of Dynamic Random Access Memory (DRAM), with 10MB of space accessible to users, ensuring fast data reading and writing and improving the system response speed. Meanwhile, it may support optional Static Random Access Memory (SRAM) expansion to meet the flexible memory capacity requirements in different application scenarios.

- Communication Ports: It has flexibly configurable serial ports, including RS 232 and RS 485 interfaces, enabling convenient data interaction with various serial devices. Additionally, it integrates Ethernet connectivity, which, with its high-speed and stable network communication capabilities, meets the strict requirements for real-time and efficient data transmission in industrial automation and facilitates seamless interconnection and communication between devices.

- Real-Time Clock: It is equipped with a fully functional real-time clock, which not only accurately records the date and time but also supports leap year calculation. This ensures that the time stamps of various data are precise during industrial production, providing a reliable basis for production traceability and process monitoring.

- Power Requirements: The operating voltage range is 10.8 - 16V DC, which can adapt to the DC power supply environments of various industrial sites. It has excellent power adaptability and stability, ensuring the module can work normally under different power supply conditions.

- Data Bus and Addressing Capability: The data bus width reaches 16 bits, providing efficient data transmission capability. The maximum addressing capacity is 64KB, which can accurately locate and manage various resources in the system, ensuring the accuracy and efficiency of data processing.

Advantages and Features

- High-Performance Computing: Leveraging an advanced microprocessor and efficient instruction set, it delivers high-speed computing capabilities, enabling rapid processing of large volumes of complex data. This meets the high demands for real-time control and data processing in industrial automation scenarios, significantly enhancing overall system operational efficiency.

- Low-Power Design: Adopting high-performance CMOS technology, it achieves low-power operation while ensuring robust computing performance. This not only reduces energy consumption and lowers operational costs but also improves the device’s heat dissipation and stability. It is particularly suitable for power-sensitive applications, such as portable industrial equipment or production workshops with strict energy management requirements.

- High Reliability: It undergoes rigorous quality control and reliability testing processes. From raw material procurement and manufacturing to finished product inspection, every stage adheres to high-standard specifications. The module can operate stably for extended periods in harsh industrial environments—such as high temperatures, high humidity, and strong electromagnetic interference—ensuring the continuity and stability of industrial production and minimizing losses caused by production disruptions due to equipment failures.

- Flexible Configurability: It supports multiple operating voltage and frequency settings, allowing users to flexibly adjust the module’s working parameters based on actual application needs. Additionally, its rich communication interfaces and expandable memory enable easy adaptation to different industrial equipment and system architectures, meeting the diverse requirements of industrial automation projects. Whether for small-scale automated production lines or large, complex industrial control systems, seamless integration can be achieved.

- Security Protection Functions: It incorporates enhanced security protection mechanisms, including firewalls, access control, intrusion detection, and data encryption. These functions effectively defend against cyberattacks and unauthorized intrusions, protecting the security and confidentiality of industrial production data. This provides solid safeguards for the information security of industrial control systems, making it especially suitable for industries with extremely high data security requirements, such as industrial automation applications in energy, finance, and other sectors.

- Easy Maintenance and Operation: It features a simple and intuitive Human-Machine Interface (HMI) menu structure, supporting multi-language display to facilitate equipment management and maintenance for operators in different regions. Meanwhile, the module’s design fully considers maintenance convenience, adopting a modular structure. When a component malfunctions, it can be quickly replaced, reducing equipment downtime and lowering maintenance costs.

Troubleshooting & FAQs

Q: What could cause the module to fail to start normally?

A: 1. Check the power supply: Ensure the voltage is within 10.8-16V DC and the power cable is not loose or broken. 2. Check hardware installation: Confirm the module is securely fixed and all interfaces are tightly connected. 3. Troubleshoot program/hardware: If the above checks are normal, try re-downloading or updating the control program. If the issue persists, the module may have hardware damage—contact professional technicians for repair.

Q: How to resolve unstable communication connections (frequent data loss or interruptions)?

A: 1. For serial communication (RS 232/RS 485): Check if the serial cable is damaged or aged, and if the interface is loose; re-plug the cable to ensure a tight connection. Confirm that serial communication parameters (e.g., baud rate, data bits, stop bits) match the connected device. 2. For Ethernet communication: Check if the Ethernet cable is functional and if there is network conflict; try replacing the cable or adjusting the module’s IP address. 3. Anti-interference: Keep the module away from strong electromagnetic interference sources (e.g., large motors, transformers) or adopt shielding measures.

Q: Is severe heat generation during module operation normal?

A: The FLN4234A CPU3680 module generates a certain amount of heat during normal operation, but overheating is abnormal. If severe heat is detected: 1. Check the installation environment: Ensure good ventilation and no obstacles blocking heat dissipation. 2. Check the module load: Confirm it is not running too many complex programs (which would cause excessive computation load). 3. Check heat dissipation components: If the above are normal, heat dissipation parts (e.g., loose heat sinks, damaged fans) may be faulty—inspect and repair promptly to avoid performance degradation or shortened lifespan due to overheating.

Q: How to update/upgrade the module’s program?

A: Typically, updates/upgrades are done via dedicated programming software. 1. Preparation: Ensure the programming software is compatible with the module; download the latest program files from Motorola’s official website. 2. Connection & operation: Connect the programming device to the module via a suitable communication interface (e.g., Ethernet or serial port). Open the software, select the correct module model and communication parameters, then upload the new program files to the module’s flash memory. 3. Precautions: Ensure stable power supply during the update to avoid interruptions. After completion, perform functional tests to confirm the module operates normally.

Customers who purchased this product are also browsing the following products:

Motorola Emerson MVME5100-0161 VMEbus Single-Board

Motorola/Emerson MVME6100 VME Single-Board Computer

GE IC698CPE020-JX PACSystems RX7i Central Processing Unit

Honeywell CC-PCF901 51405047-175 Control Firewall Module

3005319639

3005319639