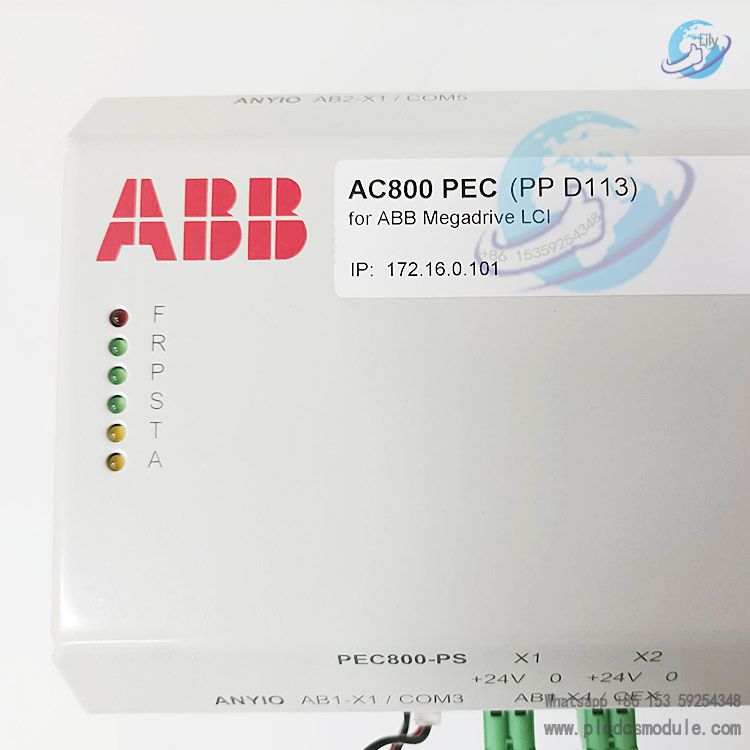

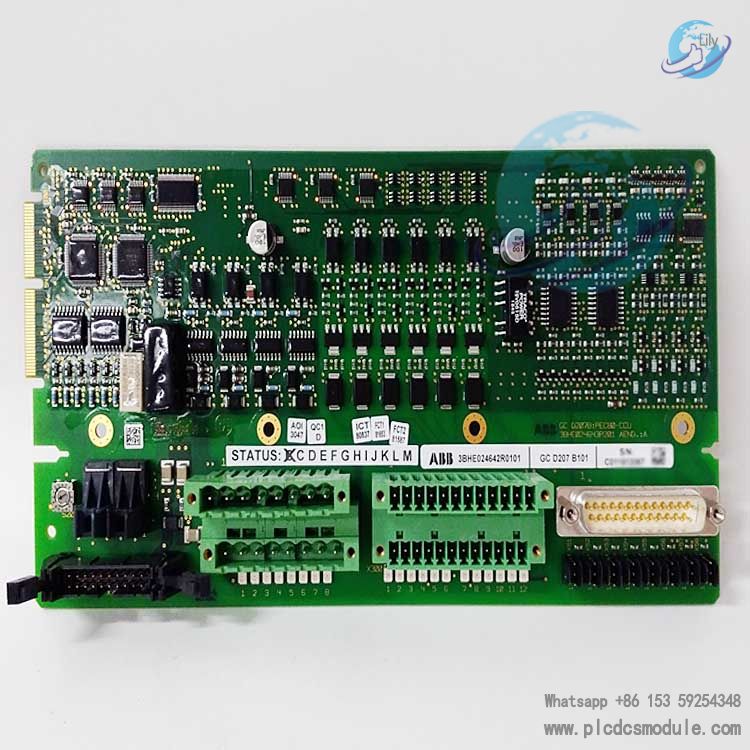

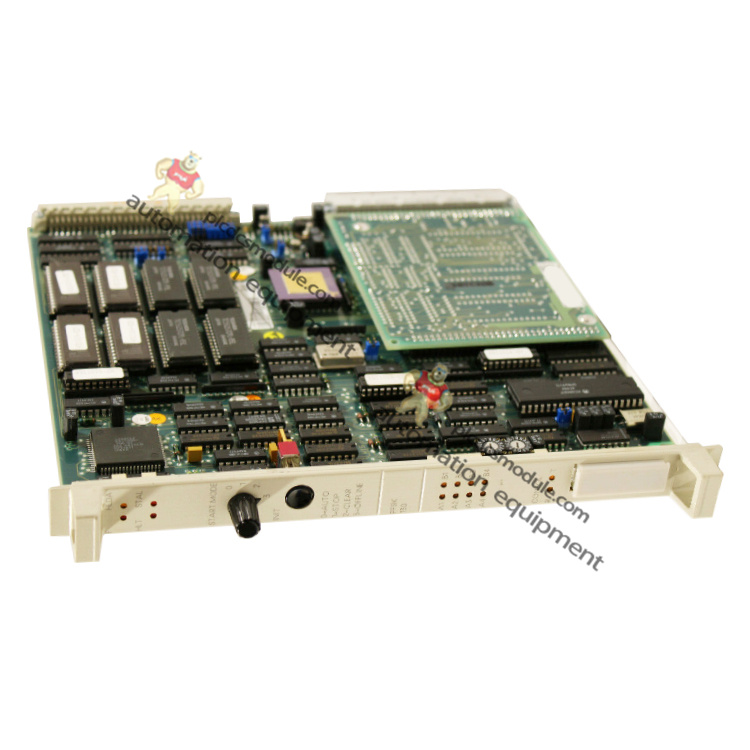

Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The ABB PPD113B03-20-110611 is a high-performance controller module in the AC 800PEC series, designed to provide stable and efficient core computing and control support for industrial process control. Integrating advanced processor chips and a modular design, this module can either independently complete local control tasks or seamlessly integrate into the AC 800PEC distributed control system to realize collaborative management of multiple devices. With "industrial-grade stability" as its core, the product has passed rigorous environmental adaptability tests (such as high/low temperature resistance, electromagnetic interference resistance, etc.) and can meet the requirements of long-term continuous operation in complex industrial scenarios.

Performance Parameters

| Parameter Category | Specific Specifications |

|---|

| Processor | 32-bit industrial-grade embedded processor, with a main frequency of ≥500MHz, supporting multi-task parallel processing |

| Memory Configuration | Program memory (Flash): ≥128MB; Data memory (RAM): ≥64MB; Memory expansion supported |

| Input/Output (I/O) Interfaces | Digital input: 8 channels (DC 24V); Digital output: 6 channels (DC 24V, maximum load of 2A per channel); Analog interface expansion supported |

| Communication Interfaces | 1 Ethernet port (supports Profinet/IEC 61850); 2 RS485 ports (supports Modbus RTU/TCP) |

| Power Supply Requirements | Rated voltage: DC 24V (±10%); Power consumption: ≤15W |

| Environmental Adaptability | Operating temperature: -25℃~+60℃; Storage temperature: -40℃~+85℃; Relative humidity: 5%~95% (non-condensing) |

| Protection Level | IP20 (module itself); Up to IP54 when adapted to standard control cabinets |

| Response Time | Digital input response: ≤1ms; Analog input response: ≤10ms; Control command output delay: ≤5ms |

| Programming Environment | Supports ABB Control Builder M programming software; Compatible with IEC 61131-3 standard programming languages (LD/FBD/ST, etc.) |

Application Fields

Relying on its stable performance and flexible compatibility, the PPD113B03-20-110611 Controller Module (AC 800PEC series) is widely applied in various industrial fields, especially suitable for scenarios with high requirements for control precision and system stability:

- Power Industry: Used in substation automation systems and power dispatching control links to realize status monitoring and precise control of equipment such as transformers and circuit breakers, ensuring stable operation of the power grid.

- Petrochemical Industry: Adapted for controlling parameters (temperature, pressure, flow, etc.) in chemical production lines; supports safety-level control in flammable and explosive environments (requires matching explosion-proof control cabinets).

- Smart Manufacturing: Serves as an automated control unit for production lines, connecting with robots, conveyors, sensors and other equipment to realize automated scheduling and fault early warning of production processes.

- Water Treatment and Environmental Protection: Used for controlling water pumps, valves and adjusting water quality parameters in sewage treatment plants; supports remote monitoring and data upload to facilitate environmental compliance management.

Metallurgy and Mining Industry: Adapted for high-temperature environment control in the smelting process of iron and steel, non-ferrous metals, as well as load adjustment and safety protection of mining equipment.

Advantages and Features

Compared with similar industrial controller modules, the PPD113B03-20-110611 (AC 800PEC series) has four core advantages based on ABB's core technology accumulation:

- High Reliability and Durability: Adopts industrial-grade dust-proof and corrosion-resistant components; passes 1000-hour continuous operation test; Mean Time Between Failures (MTBF) ≥100,000 hours, suitable for harsh industrial environments.

- Flexible Expandability: Supports modular I/O interface expansion (up to 32 I/O channels); compatible with third-party sensors and actuators to meet changing control requirements in different scenarios.

- Efficient Communication and Collaboration Capability: Built-in multi-protocol communication interfaces, enabling quick integration into the ABB AC 800PEC distributed system; meanwhile, supports seamless connection with PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition) systems to realize real-time data interaction and remote control.

- Ease of Use and Low Maintenance Cost: Supports online programming and fault diagnosis; intuitively displays operating status (normal/fault/communication interruption) through LED indicators, reducing on-site maintenance time; with highly versatile spare parts, lowering long-term operation and maintenance costs.

Working Principle

The working logic of the PPD113B03-20-110611 Controller Module (AC 800PEC series) is based on a closed-loop control process of "signal acquisition - operation processing - command output", which is detailed as follows:

- Signal Acquisition Stage: Through built-in or expanded I/O interfaces, real-time collect digital/analog signals output by on-site sensors (such as temperature sensors, pressure sensors, position sensors, etc.) and convert them into electrical signals recognizable by the controller.

- Operation Processing Stage: Based on the control program (such as logic control, PID adjustment, etc.) pre-written via Control Builder M software, the built-in processor performs operation and analysis on the collected signals to determine whether the current equipment operation status meets the set targets.

- Command Output Stage: If the operation result indicates that the equipment status needs to be adjusted, the controller sends control commands to actuators (such as valves, motors, relays, etc.) through output interfaces to realize precise adjustment of industrial processes; meanwhile, uploads real-time operation data to the upper-level control system (such as SCADA) for managers to monitor and make decisions.

During the entire process, the built-in redundancy check mechanism of the module performs real-time verification on data, avoiding control errors caused by signal interference or hardware failures, and ensuring control precision and system stability.

Installation Steps

In accordance with ABB's official installation guidelines, the installation of the PPD113B03-20-110611 Controller Module (AC 800PEC series) shall follow the principle of "safety specifications first, accurate connection first". The steps are as follows (operation by professional electricians or automation engineers is recommended):

(1) Pre-installation Preparation

- Confirm that the installation environment meets the requirements: Temperature inside the control cabinet ≤60℃; No obvious dust or corrosive gas; Keep away from strong electromagnetic interference sources (such as high-power motors).

- Prepare tools: Phillips screwdriver, wire crimping tool, multimeter, insulating gloves, etc.

- Inspect the module appearance: Confirm no damage to the module, no bent pins, and complete attached interface terminals and fixing screws.

(2) Module Fixing

- Open the control cabinet, align the module with the guide rail slot (compatible with standard 35mm DIN rail), push it along the guide rail and press down until the module buckle is tightly attached to the guide rail.

- Lock the fixing holes on both sides of the module to the inner wall of the control cabinet with screws to prevent the module from shifting due to vibration.

(3) Wiring Operation

- Connect the power cable under power-off condition: Connect the positive pole of DC 24V to the "+V" terminal of the module, and the negative pole to the "-V" terminal; Use a multimeter to check if the voltage is normal after wiring.

- Connect the I/O interfaces: According to the wiring diagram, connect the sensor signal wires to the "DI" (Digital Input) or "AI" (Analog Input) terminals, and the actuator control wires to the "DO" (Digital Output) or "AO" (Analog Output) terminals; Each wire shall be pressed tightly to avoid poor contact.

- Connect the communication cable: For Ethernet connection, insert the network cable crystal head into the "Ethernet" interface; For RS485 connection, connect the A/B wires to the "RS485 A" and "RS485 B" terminals respectively.

(4) Power-on Test

- Turn on the power of the control cabinet and observe the module LED indicators: The "Power" light is always on (green) indicating normal power supply; The "Run" light flashes (green) indicating the module is operating normally.

- Connect the module via Control Builder M software and check if the communication is normal: If the "Com" light is always on (yellow), it means the communication has been established.

(5) Fixing and Protection

Comparison with Similar Products

To help users clearly judge the advantages in model selection, the PPD113B03-20-110611 (AC 800PEC series) is compared with similar products on the market (ABB PPD112B02-15-110501) as follows:

| Comparison Dimension | ABB PPD113B03-20-110611 (AC 800PEC Series) | ABB PPD112B02-15-110501 (AC 800PEC Series) |

|---|

| Core Performance | Main frequency: 500MHz; 128MB Flash + 64MB RAM | Main frequency: 300MHz; 64MB Flash + 32MB RAM |

| I/O Expansion Capability | Maximum expandable to 32 channels | Maximum expandable to 16 channels |

| Communication Protocol Support | Supports Profinet/IEC 61850/Modbus RTU/TCP | Only supports basic Modbus RTU/TCP protocols |

| Environmental Adaptability | Operating temperature: -25℃~+60℃; IP20 (module itself) | Operating temperature: -10℃~+50℃; IP20 (module itself) |

| Compatibility | Fully compatible with ABB AC 800PEC system; Supports third-party equipment expansion | Compatible with ABB AC 800PEC system; Limited third-party equipment expansion |

| Price Range | Mid-to-high end (outstanding cost-effectiveness) | Mid-range (basic function model) |

User Reviews

Based on real user reviews from ABB's official customer feedback platform and industrial automation forums (typical cases selected), the actual usage experience of the product can be intuitively understood:

- User from the Power Industry: "We upgraded the substation control system to AC 800PEC series in 2023, with the PPD113B03 module as supporting equipment. It has been operating for nearly a year without failures. The module has extremely high control precision for transformer temperature, with an error ≤0.5℃. Moreover, real-time data connection with the dispatching center is realized through the Ethernet interface, which greatly improves the operation and maintenance efficiency."

- User from a Chemical Enterprise: "The chemical workshop has high humidity and strong corrosiveness, and the third-party controller we used before frequently failed. After replacing it with the ABB PPD113B03, it has operated stably and reliably for 6 consecutive months. Especially the fault diagnosis function is very practical—problems can be quickly located through indicators and software, reducing equipment downtime."

User from Smart Manufacturing: "The production line needs to connect with multiple robots and sensors, and the expansion capability of the PPD113B03 module fully meets our needs. We have additionally expanded 24 I/O channels, and no compatibility issues have occurred so far. In addition, the module is easy to program, allowing technicians to get started quickly, which reduces training costs."

Frequently Asked Questions (FAQ)

Q: The "Power" light does not turn on after the module is powered on. How to troubleshoot?

A: First, check if the positive and negative poles of the power cable are reversed (connect the positive pole to "+V" and the negative pole to "-V"); Second, use a multimeter to check if the power supply voltage is within the range of DC 22.5V~26.5V; If the voltage is normal, the module's power interface may be faulty. It is recommended to contact ABB after-sales service to replace the module.

Q: The module cannot establish communication with Control Builder M software. What should I do?

A: Step 1: Confirm that the network cable connection is normal (you can replace the network cable for testing); Step 2: Check the "communication parameters" settings in the software (the IP address and port number must be consistent with those of the module); Step 3: Turn off the firewall or anti-virus software in the control cabinet to avoid port blocking; If the connection still cannot be established, the module's Ethernet interface may be faulty, and technical support should be contacted.

Q: The "Fault" light is always on (red) during the module operation. How to handle it?

A: A constantly on "Fault" light indicates that the module has hardware or program faults. First, read the fault code through the software (e.g., "E001" indicates a memory error); If it is a program error, the control program can be re-downloaded; If it is a hardware error (e.g., "E005" indicates an I/O interface fault), stop the equipment operation, replace the module, and contact ABB after-sales service for repair.

Customers who purchased this product are also browsing the following products:

ABB S-073R 3BHB009884R5331 PHASE MODULE

ABB 3BHE031197R0001 Medium Voltage (MV) Converter

Honeywell FC-SDO-0824 Safe Digital Output Module

HIAM F8620 Central Processing Unit (CPU) module

3005319639

3005319639