Key Technical Specifications

The GE DS200SDCIG1ABA module boasts standardized technical parameters tailored to industrial control requirements, with core specs validated by GE technical documentation and industry applications:- Input Voltage: 115-230 VAC (allowable range: 90-260 VAC) or 24 VDC (dual input compatibility for flexible deployment)

- Input Frequency: 50-60 Hz (allowable range: 47-63 Hz)

- Output Voltage: 3.3 VDC (±3% accuracy) and 5.0 VDC (±3% accuracy), ensuring stable power for logic circuits and interface components

- Output Current: 0.5 A to 5 A, with a maximum output power of 26.5 W

- Operating Temperature Range: -40°C to +70°C, suitable for extreme industrial environments

- Physical Dimensions: 5.3 x 3.9 x 2.2 inches (134.62 x 99.06 x 55.88 mm), compact design for easy installation

- Weight: Approximately 0.75-0.8 pounds (0.34-0.36 kg)

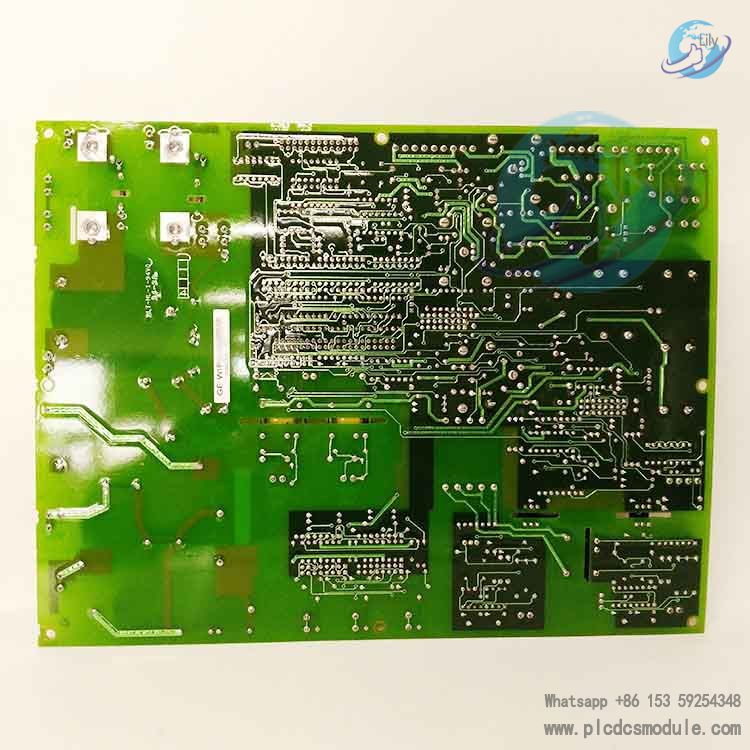

- PCB Coating: Normal coating, providing protection against dust, moisture, and industrial contaminants

- Fuse Configuration: Equipped with multiple fuses (FU1: 115 VAC power fuse; FU2/FU3: DC signal-level power supply fuses) with LED indicators for fault detection

- Communication Protocols: Supports Ethernet, Modbus TCP/IP, and OPC for seamless integration with industrial control networks

Core Functions & Features

Designed for turbine control system optimization, the DS200SDCIG1ABA combines power supply stability and signal processing precision, featuring the following key capabilities:- Stable DC Power Supply: Delivers regulated 3.3 VDC and 5.0 VDC output with ±3% accuracy, ensuring reliable operation of Mark V control system components and DC2000 drives .

- Signal Conditioning & Conversion: Converts analog signals (e.g., temperature, pressure, flow sensor readings) from field devices into digital signals usable by the turbine control system, while filtering and amplifying signals to improve data accuracy .

- Device Interface: Acts as an intermediary between the Mark V control system and field devices (sensors, actuators), facilitating bidirectional signal transmission and ensuring compatibility with DC2000 drives .

- Multiple Protection Mechanisms: Integrates overvoltage, overcurrent, voltage/frequency anomaly, and power supply fault protection, safeguarding both the module and connected control components .

- Modular Design: Standardized form factor and interface enable easy integration with existing Mark V turbine control systems, simplifying maintenance and replacement .

- Built-in Diagnostics: Features fault detection capabilities and fuse LED indicators, allowing for quick identification of power supply or signal anomalies to minimize downtime .

Applications & Industry Use Cases

As a core component of the GE Mark V series, the DS200SDCIG1ABA is primarily deployed in turbine control and industrial automation scenarios, with key applications including:- Power Generation: Used in gas turbine, steam turbine, and wind turbine control systems in power plants, ensuring stable operation during start-up, shutdown, and load management .

- Oil & Gas Industry: Deployed in offshore drilling platforms and onshore refineries to power and control turbine-driven equipment .

- Industrial Automation: Integrated into PLC systems and manufacturing line control systems, providing power and signal processing for automation equipment .

- Renewable Energy: Utilized in wind and solar power facilities where turbines are part of the energy generation process, supporting reliable control system operation .

- Water Treatment: Powers automation control systems in water treatment plants, ensuring consistent performance of monitoring and control devices .

Customers who purchased this product are also browsing the following products:

FOXBORO RH916XZ Discrete Input Module

Bently Nevada 3500/42M-01-00 Proximitor Seismic Monitor

kongsberg RCU501 Remote Controller Unit module

ABB DSAI133A 3BSE018290R1 Analog Input Board

3005319639

3005319639