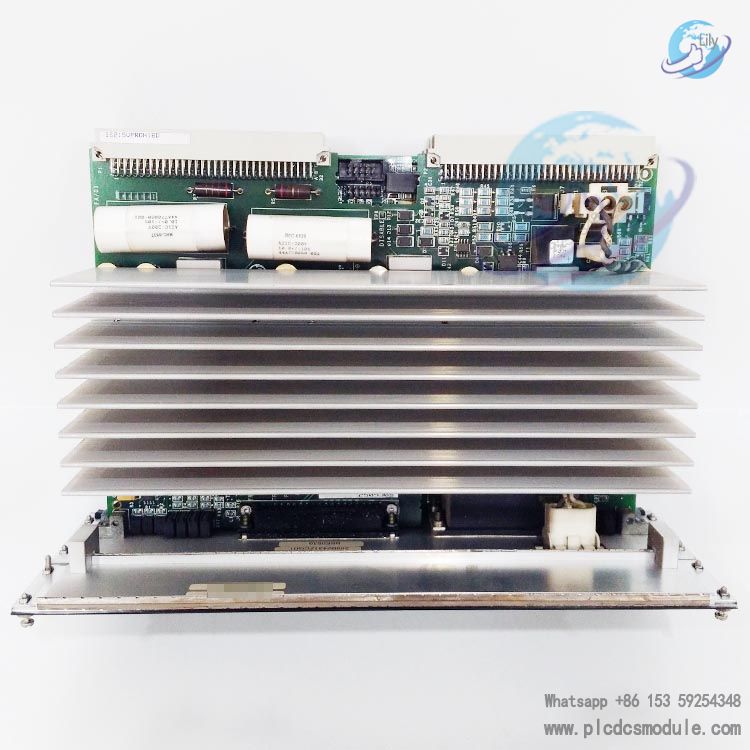

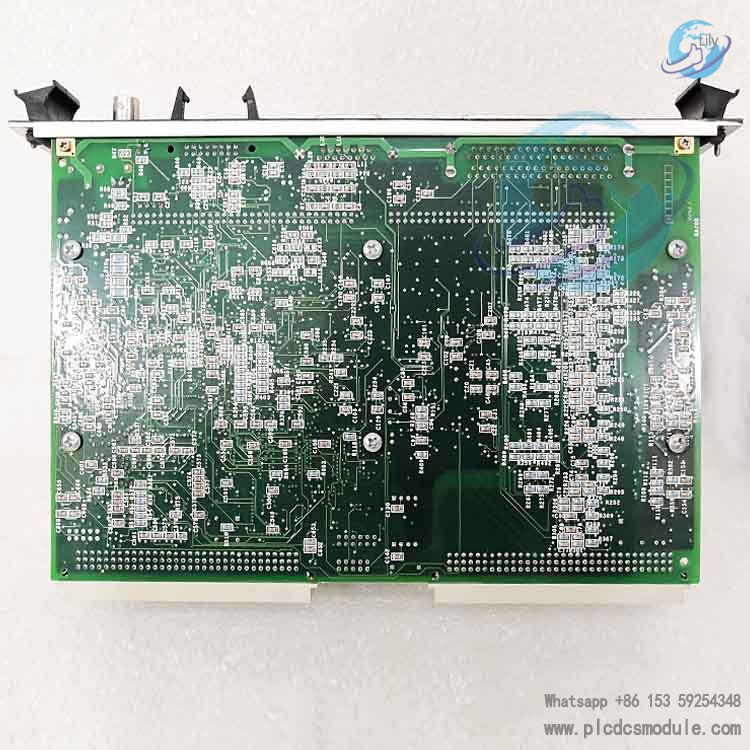

The GE IS215VPROH1BD is an RTD (Resistance Temperature Detector) input module integrated into the GE Speedtronic Mark VI steam turbine control system, and also features emergency turbine protection functionality. Primarily designed for temperature monitoring and overspeed protection of gas and steam turbines, it achieves precise measurement of temperatures at key components of the turbine unit by acquiring RTD signals. It collaborates with other system modules to execute protective actions such as emergency shutdown and trip control, ensuring the stable and safe operation of the unit under all operating conditions. Compliant with stringent standards in the industrial automation sector and suitable for harsh industrial environments, it provides critical support for the reliable operation of the Mark VI system.

Core Functions

- RTD Signal AcquisitionSupports multi-channel 3-wire RTD inputs and is compatible with a variety of RTD sensors (e.g., PT100). It performs real-time temperature acquisition for critical components of steam turbines such as bearings, windings and exhausts. Multiplexing technology is adopted during the acquisition process to ensure high efficiency and accuracy of signal collection.

- Signal Processing and ConversionEquipped with a built-in high-precision A/D converter, it converts the resistance signals from RTD sensors into digital signals, which are then linearized by a digital signal processor. It is compatible with more than 15 types of RTDs to meet temperature measurement requirements in different scenarios. Meanwhile, it features a high-frequency decoupling design to effectively suppress signal interference and ensure data stability.

- Emergency Protection FunctionIntegrates protection logic including overspeed protection, speed difference detection and backup synchronization check, and is capable of receiving thermocouple and analog input signals. When dangerous operating conditions such as abnormal temperatures or unit overspeed are detected, it rapidly triggers trip solenoid valve control to execute emergency shutdown and prevent equipment damage.

- Status Monitoring and DiagnosticsComes with LED indicators that intuitively display status information such as power supply, signal acquisition and system faults, facilitating quick troubleshooting by maintenance personnel. It also supports real-time communication with the system controller, uploading temperature data and module operating status to provide a basis for remote monitoring and fault diagnosis.

- Redundancy Configuration SupportCompatible with Triple Modular Redundancy (TMR) configuration. Input signals can be distributed to three VRTD boards via the terminal board to achieve redundant RTD input design, which enhances the fault tolerance and reliability of the system and ensures uninterrupted system operation even if a single module fails.

Technical Specifications

Structural Features

Application Scenarios

- Temperature monitoring and protection systems for steam turbines in large thermal power plants.

- Control of gas turbine-driven compressor units in the petrochemical sector.

- Steam turbine power generation systems in the metallurgical industry.

- Other industrial automation control scenarios requiring high-precision temperature monitoring and emergency protection.

Customers who purchased this product are also browsing the following products:

GE IS215UCCCM04AB CPCI Controller Board

GE IC693CMM321 Ethernet Interface module

GE 531X307LTBAHG1 EX2000 LAN Terminal Board

3005319639

3005319639