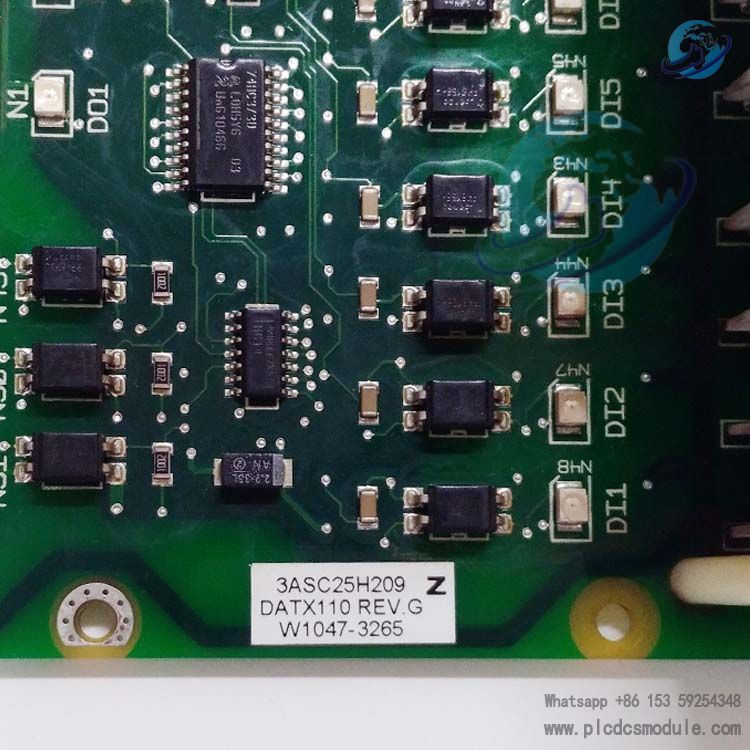

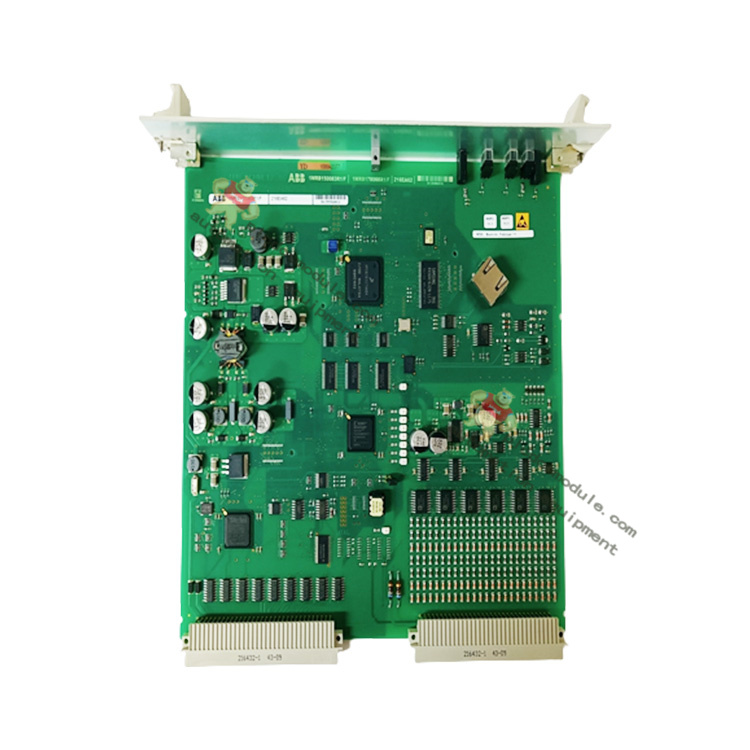

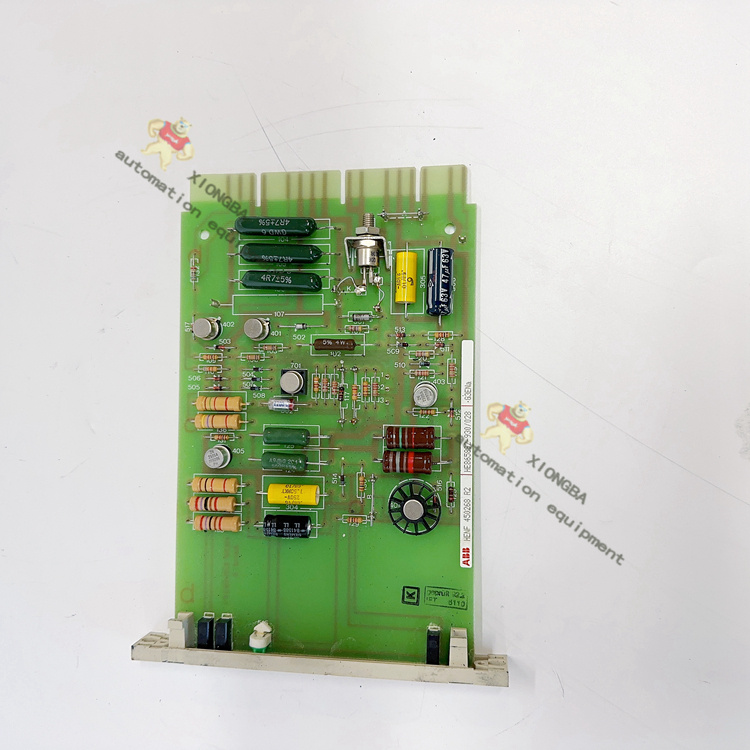

ABB DATX110 (Product IDs: 3ASC25H209, 3BSC980004R784) is an I/O board without analog output (No AO), specially designed for the ASTAT crane motion control system, serving as the core interface bridge between the control module and external devices. It integrates the functions of digital input/output, analog input and pulse encoder interface, and is suitable for crane drive scenarios with a voltage range of 380-690V and a current rating of 25-2000A. Featuring industrial-grade characteristics such as dust resistance and wide temperature tolerance (-25°C to +70°C), it acts as a critical component for signal acquisition, command transmission and equipment linkage in the ASTAT system.

related documents

Core Functions and Interface Configuration

Digital I/O Interface

- Digital Input (DI)It provides 17 channels of 110V DC input channels, supporting the access of signals such as limit switches, master switch zero signals, fault reset, and mechanical overload detection. Part of the channels can be configured as parameter group selection and operation station switching functions via parameters.

- Digital Output (DO)It includes 8 channels of output channels, which can directly drive executive components such as rotor contactors (K0-K3), brake lifting contactors, and fault alarm relays. Among them, DO1 can be programmed via parameters for specific functions such as thyristor fan control and cable reel drive.

Analog Input Interface

Pulse Encoder Interface

Key Technical Parameters

- Power Supply SpecificationsThe control voltage is compatible with 110V DC (internal power supply), and the analog reference voltage is ±10V.

- Protection ClassIt has an IP20 protection rating and complies with industrial pollution degree 4 (EN 60664), suitable for the dusty environment of crane electrical rooms.

- Installation CompatibilityIt is seamlessly compatible with DARA 1000/1001/1010 control modules of the ASTAT series, and supports fiber optic communication for extended I/O.

- Signal ResponseThe response time of digital signals is ≤10ms, and the analog input resolution is 11-bit + sign bit, ensuring control accuracy.

Typical Application Scenarios

- Crane Core Control LinkServing as the interface between the DARA control module and devices such as master control consoles, limit switches, brakes, and rotor contactors, it enables signal interaction for movements including hoisting, luffing, and slewing.

- Fault Monitoring and ProtectionBy collecting motor PTC temperature, overload signals, and limit switch status, it cooperates with the ASTAT system to achieve rapid response and shutdown protection against faults such as over-temperature, overload, and over-travel.

- Multi-device Linkage ControlIt supports signal transmission for the Master-Follower control architecture, and the DI17 channel can be used to implement synchronous control or emergency stop functions for master and slave devices.

Configuration and Commissioning Features

- Parameter ProgrammabilityChannel functions (such as DI/AI usage and DO output logic) can be configured via the ASTAT Tool software, which supports offline parameter configuration and online synchronization.

- Diagnostic FunctionIt supports real-time monitoring of signal status, and the input/output signal status can be read via software, facilitating fault location and maintenance.

- ScalabilityIt supports fiber optic expansion with Cabin I/O modules (e.g., DAPM 100), adapting to application scenarios involving multi-operator stations and multi-motor control.

Customers who purchased this product are also browsing the following products:

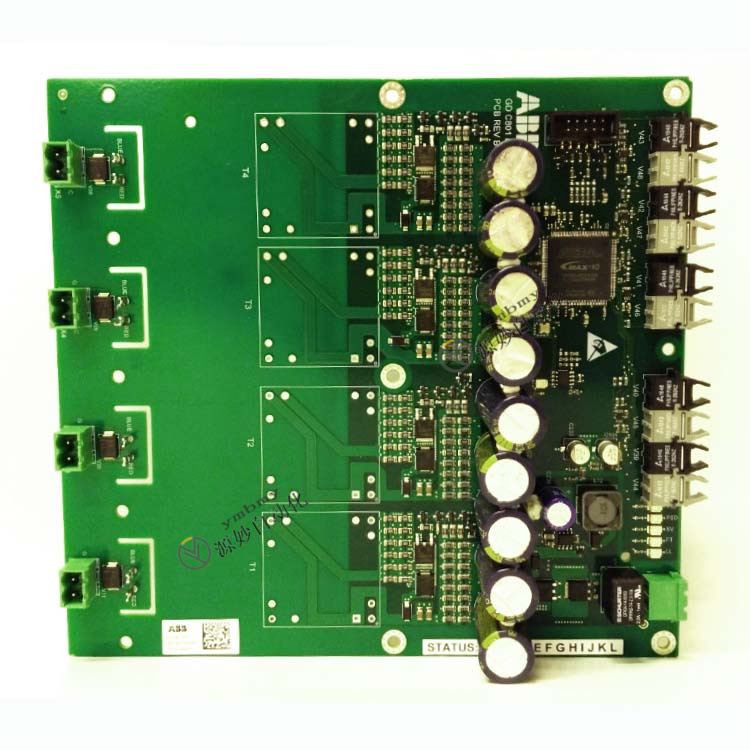

ABB S-093M 3BHB009885R0063 Medium and high voltage phase module ACS 6000

ABB PPD115A02 3BHE017628R0002 PEC800-PS Controller Module

ABB UFC760BE145 3BHE004573R0145 Frequency I/O board

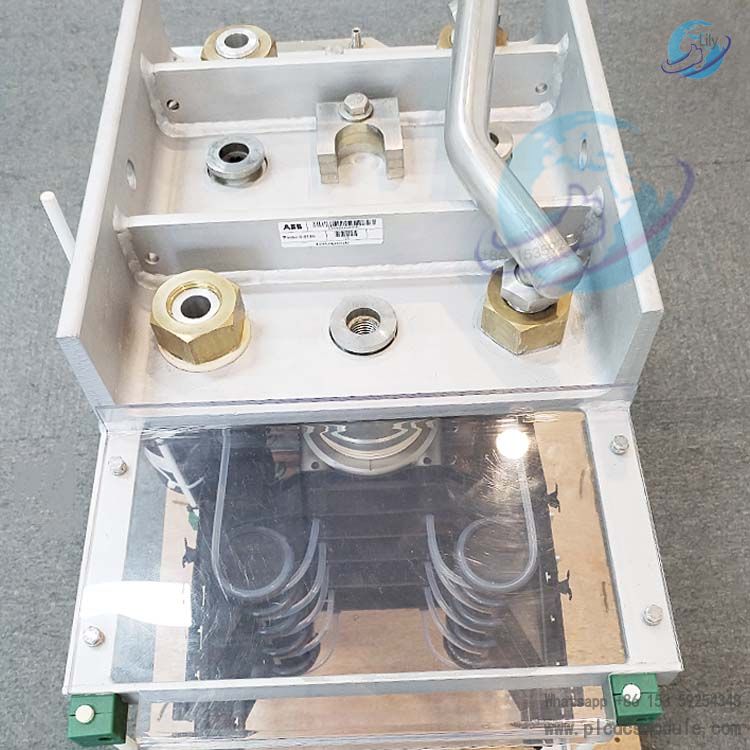

ABB 5SHY3545L0009 3BHB013085R0001 Thyristor Module

3005319639

3005319639