Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. Basic Positioning and Core Functions

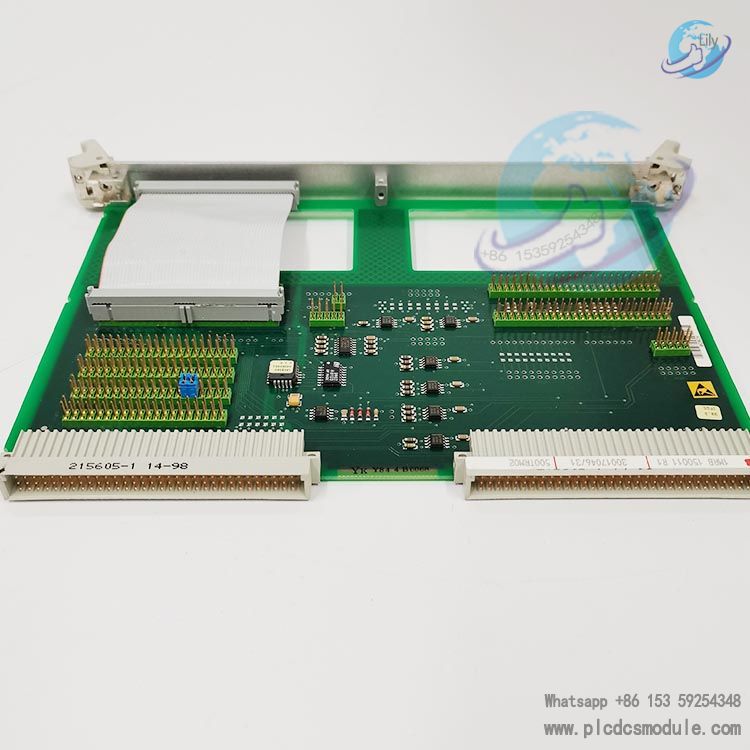

The ABB 500TRM02 1MRB150011R1 coupler module mainly undertakes the role of data interaction and communication bridging between various components of the system. As a key node connecting different functional modules or subsystems, it can realize efficient transmission and conversion of control signals and status data, ensuring the collaborative operation of the entire automation system.

500TRM02 1MRB150011R1 Technical Features and Advantages

- Multi-protocol compatibility: Supports various industrial bus protocols (such as PROFINET, Modbus, etc.), enabling seamless connection with automation equipment of different brands and protocols, and solving the problem of system heterogeneity.

- High-speed data transmission: Equipped with a high communication rate, it can quickly process large amounts of real-time data, meeting the strict requirements for response speed in industrial scenarios and avoiding control deviations caused by data delays.

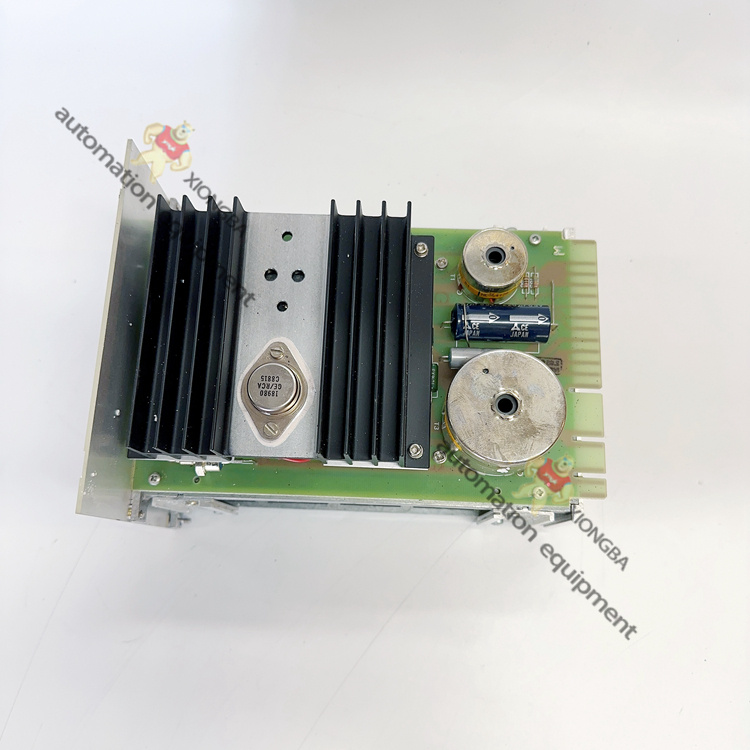

- Stable connection performance: Adopts industrial-grade hardware design with excellent anti-electromagnetic interference capability. It can maintain stable connections even under complex working conditions such as strong electromagnetic environments and voltage fluctuations, ensuring the integrity of data transmission.

- Support for modular expansion: Following the modular design concept, it can be flexibly combined with related modules such as the ABB AC500 series. It can be expanded according to the needs of system scale, simplifying the process of system construction and upgrading.

- Diagnostic and fault-tolerant functions: Built-in fault diagnosis mechanism can monitor communication status in real time. When abnormalities such as connection interruption and data errors occur, it can send alarm signals in a timely manner, facilitating maintenance personnel to quickly locate problems; partial redundant design can ensure the basic communication functions of the system in case of single-point faults.

500TRM02 1MRB150011R1 Reference for Hardware Parameters

- Power Supply Voltage: Typically supports 24V DC industrial standard voltage, compatible with common power supply systems in industrial sites.

- Communication Interfaces: Equipped with multiple bus interfaces (such as Ethernet ports, RS-485 interfaces, etc.). The specific quantity and types are subject to official documents.

- Operating Environment: The operating temperature range is generally -20°C to +60°C, with a relative humidity of 5%-95% (non-condensing), adapting to harsh industrial environments such as dust and vibration.

- Installation Method: Supports rail mounting, conforming to the standardized installation specifications of industrial automation systems, and is easy to integrate into control cabinets.

Typical Application Scenarios

- Production Line Automation: In automated production lines of industries such as automobile manufacturing and electronic processing, it connects PLC controllers, robots, sensors, actuators and other equipment to realize collaborative control and data interaction among various links.

- Process Control Systems: In process control scenarios such as chemical industry and food processing, as a communication node of the distributed control system (DCS), it connects on-site instruments and central control units to ensure real-time collection of production parameters and accurate issuance of control commands.

- Smart Factory Integration: Under the framework of Industry 4.0, it is used to connect subsystems in different areas (such as warehouse management, equipment monitoring, energy monitoring, etc.), build a unified data transmission network, and provide communication support for intelligent manufacturing.

Customers who purchased this product are also browsing the following products:

ABB PPC380AE01 HIEE300885R0001 Control Module

ABB 3BHE031197R0001 Medium Voltage (MV) Converter

Bently Nevada 3500/42M-01-00 Proximitor Seismic Monitor

tricon 3503E 24 Vac/Vdc Digital Input Module

3005319639

3005319639