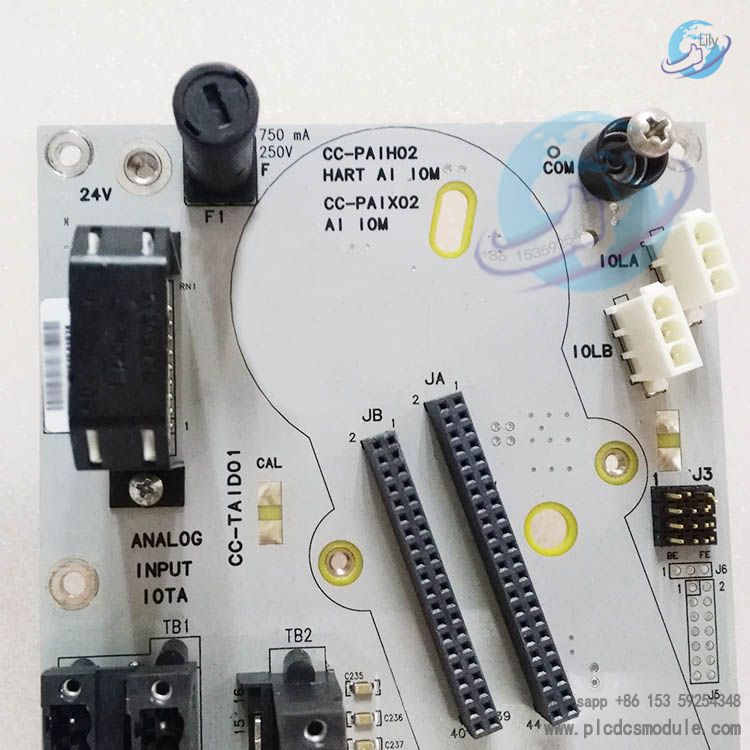

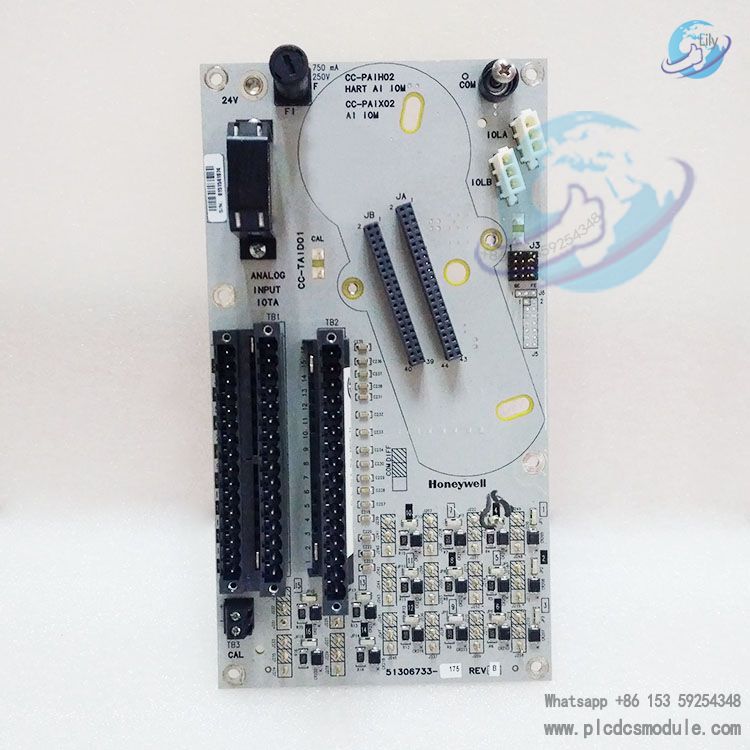

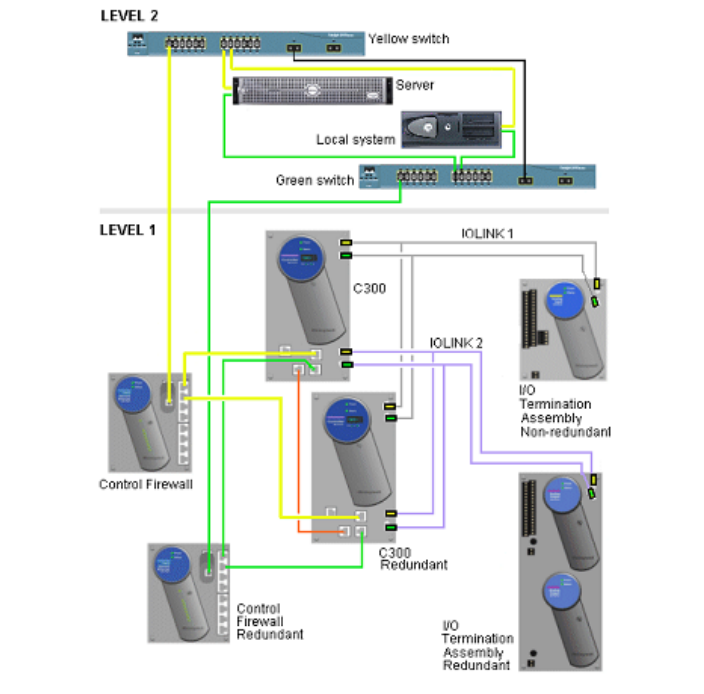

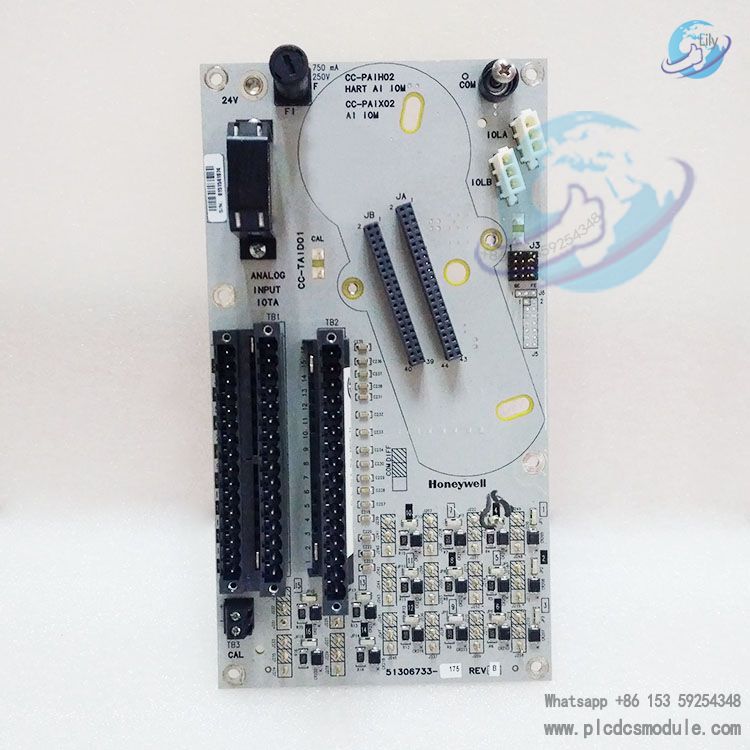

Honeywell CC-TAID01 51306733-175 is an analog input terminal module specially designed for industrial automation control systems. Its core function is to serve as a "signal transfer and preprocessing center" between on-site analog signals (such as continuously changing physical quantity signals like temperature, pressure, and flow) and the control system. By accurately collecting on-site analog signals, performing filtering for noise reduction, and conducting standardized conversion, it provides stable and reliable input signals for the controller, thereby ensuring the control system's precise monitoring and regulation of industrial production processes.

Meanwhile, this module is deeply integrated into the Honeywell Experion PKS (Process Knowledge System) architecture. Adopting industrial-grade hardware design and high-precision signal processing technology, it differs from ordinary analog input terminals in that it has undergone specialized optimization in terms of signal acquisition accuracy, anti-interference capability, and environmental adaptability. It can be directly connected to various on-site sensing devices such as thermocouples, resistance thermometers, and pressure transmitters. Therefore, it is widely used in industrial scenarios with strict requirements for analog signal acquisition accuracy, including petrochemicals, electric power, and metallurgy, and has become a core supporting component in the analog signal acquisition link of industrial automation systems.

Performance Parameters

Signal Acquisition Capability

Signal Processing Characteristics

Power Supply and Power Consumption

Environment and Protection

Physical and Mounting Specifications

Advantages and Features

Multi-Signal Compatibility, Reducing Module Quantity

Unlike most analog input terminals that only support a single type of signal, this assembly is compatible with four signal types simultaneously: thermocouple, RTD (Resistance Temperature Detector), voltage, and current. Its 8 channels can be flexibly configured for different signal types. For example, in the same control cabinet, it can simultaneously collect thermocouple temperature from a reaction kettle, current signals from a pipeline pressure transmitter, and voltage signals from a tank level transmitter. There is no need to configure separate terminal modules for different signals, which reduces the number of modules in the cabinet and lowers system integration costs and wiring complexity.

Ultra-High Acquisition Accuracy, Ensuring Control Precision

With an acquisition accuracy of ±0.1°C for thermocouple signals, ±0.05°C for RTD signals, and ±0.02% of full scale for voltage/current signals, this assembly far outperforms most analog terminal assemblies in the industry (which typically have an accuracy of ±0.5°C/±0.1% of full scale). In scenarios with strict requirements for parameters such as temperature and pressure (e.g., pharmaceutical fermentation, semiconductor manufacturing), it ensures that the signals obtained by the control system are highly consistent with the actual on-site working conditions, avoiding control deviations caused by signal errors.

Intelligent Anti-Interference and Signal Optimization for Stable Transmission

It adopts a dual anti-interference design of "8th-order low-pass filtering + electromagnetic shielding housing":

The 8th-order low-pass filter can accurately filter out 50/60Hz power frequency interference and high-frequency noise, and the filter cutoff frequency is software-adjustable to adapt to different interference environments.

The metal shielding housing can block external electromagnetic radiation (such as interference generated by workshop frequency converters and motors).

At the same time, the automatic cold-junction compensation function for thermocouples eliminates the need for additional compensation wires, which not only reduces costs but also avoids signal loss caused by compensation wires, ensuring stable signal transmission.

Wide Temperature Range and High Protection, Adapting to Extreme Scenarios

With an operating temperature range of -40°C to +70°C, which is significantly wider than that of conventional analog terminals in the industry (-20°C to +60°C), it can be directly applied to extreme temperature scenarios such as outdoor control cabinets in northern winter (e.g., oilfield wellhead monitoring) and unairconditioned metallurgical workshops in southern summer, without the need for additional heating or cooling devices. The IP20 protection rating and dust-proof terminal design also enable it to adapt to dusty industrial environments (e.g., cement production workshops), extending the service life of the assembly.

Quick Installation and Parameter Configuration, Improving Operation and Maintenance Efficiency

It adopts a DIN rail quick-buckle design—no screws need to be removed during installation; fixation can be completed by aligning with the rail and pressing down, reducing installation time by 70% compared with the traditional screw-fixing method. Module parameter configuration is done through the Honeywell Experion PKS system software, which supports a "one-click parameter copy" function. During batch configuration of multiple modules, the parameters of one module can be quickly copied to other modules, eliminating the need for manual setting of each channel and greatly improving operation and maintenance efficiency.

Application Fields

Petrochemical Industry: Reactor Temperature Monitoring

In the crude oil cracking reactor system, this assembly collects K-type thermocouple signals (0-1372°C) from different areas of the reactor body. Its built-in cold-junction compensation function eliminates the impact of ambient temperature on measurements, while the 8th-order filter filters out electromagnetic interference generated by workshop compressors and pump units. This ensures a reaction temperature acquisition accuracy of ±0.1°C, providing precise data for the control system to adjust heating power and preventing substandard cracking products caused by excessive temperatures.

Power Industry: Boiler Drum Parameter Monitoring

It is adapted to the boiler drum monitoring system of thermal power plants, collecting 4-20mA signals from drum pressure transmitters (with an accuracy of ±0.02% of full scale) and PT100 RTD signals from steam pipelines (4-wire, ±0.05°C). Its ability to withstand low temperatures of -40°C makes it suitable for outdoor control cabinet environments in northern winters, ensuring stable transmission of boiler drum water level, pressure, and temperature data, and preventing boiler dry firing or waterlogging accidents caused by abnormal water levels.

Metallurgical Industry: Hot-Rolled Steel Strip Temperature Measurement

In the hot-rolling production line of iron and steel plants, the assembly collects R-type thermocouple signals (0-1768°C) at the exit of the rolling mill. With a high sampling rate of 10Hz, it captures real-time temperature changes of the steel strip (10 samples per second). Its vibration-resistant design (1g acceleration) resists strong vibrations during the rolling mill's operation, providing real-time temperature data for the control system to adjust roll pressure and speed, and ensuring the thickness deviation of the rolled steel strip is ≤0.01mm.

Pharmaceutical Industry: Fermentation Tank Environment Monitoring

It is used for pH value and temperature monitoring of pharmaceutical fermentation tanks, collecting 4-20mA signals from pH transmitters (±0.02% of full scale) and PT100 RTD signals inside the tank (±0.05°C). The metal shielding housing and 8th-order filtering function filter out electromagnetic interference from agitator motors, and its ability to withstand high humidity of 95% adapts to the humid environment of fermentation workshops. This ensures precise pH value (accuracy ±0.01pH) and temperature (±0.1°C) data, complying with GMP production standards.

Food Processing Industry: Dairy Product Sterilization Control

In the UHT (Ultra-High Temperature) sterilization system for dairy products, the assembly collects PT100 RTD signals from the sterilization tank (3-wire, 0-150°C). An acquisition accuracy of ±0.05°C ensures the sterilization temperature is controlled at 137°C±0.1°C, meeting the strict temperature requirements of pasteurization. The dust-proof terminal design prevents poor signal contact caused by milk powder dust accumulation, ensuring continuous and stable sterilization processes.

Frequently Asked Questions

Q: After the module is powered on, the communication light does not flash and it fails to communicate with the controller. How to solve this problem?

A: Troubleshoot in three steps: ① Check if the bus plug is fully inserted (a "click" sound should be heard), then reinsert the bus plug; ② Use a multimeter to measure the voltage of the bus interface (it should be 5.0-5.2VDC). If the voltage is abnormal, check the controller's bus power supply; ③ Access the "Module Search" function in the software to confirm whether the module model is correctly identified. If not identified, restart the controller and search again.

Q: There is a large deviation between the thermocouple signal collection value and the actual temperature (e.g., actual temperature is 500°C, displayed temperature is 495°C). What is the reason?

A: Prioritize checking the following two points: ① Confirm whether the thermocouple type is consistent with the module configuration (e.g., a K-type thermocouple must be configured as "K-type" instead of "J-type"); ② Check if the thermocouple wiring is reversed (connecting "T+" to the negative pole and "T-" to the positive pole will cause deviation), and re-verify the wiring polarity. If the deviation persists, access the software calibration interface and perform accuracy calibration using a standard signal generator.

Q: The module fails to start in a low-temperature environment of -30°C. How to handle this?

A: This is caused by the drop in bus supply voltage at low temperatures. Solutions: ① Check if the cabinet has air leakage, and install thermal insulation cotton to reduce heat loss; ② Connect a 1000μF/16V capacitor in parallel at the bus power supply terminal to improve power supply stability at low temperatures; ③ If the module is used in an environment below -30°C for a long time, the Honeywell low-temperature heating kit (model HT-KIT01) can be purchased to ensure the module's operating temperature is ≥-40°C.

Q: The collection value of a certain current signal fluctuates greatly (e.g., 4-20mA signal fluctuates between 3.8-4.2mA). How to solve this?

A: This is mostly due to interference or wiring issues: ① Check if the cable of this channel uses a shielded twisted pair and if the shield layer is grounded at one end (connected to the control cabinet ground bar); ② Access the software and adjust the filtering frequency of this channel from the default 1Hz to 5Hz to enhance anti-interference capability; ③ Use a multimeter to measure whether the transmitter's output current is stable. If the transmitter itself fluctuates, the transmitter needs to be repaired.

Q: The module fault light is on, and the software prompts "Channel 3 Overcurrent". How to troubleshoot?

A: ① Disconnect the load cable of this channel and use a multimeter to measure the resistance between the terminals (normally ≥100Ω; if short-circuited, the resistance is close to 0). If short-circuited, check if the load device (such as a transmitter) is faulty (e.g., internal coil short-circuit, terminal adhesion), replace the faulty load, and rewire for testing; ② If the load is normal (resistance ≥100Ω), use a clamp ammeter to measure the channel input current (normally ≤25mA, the module's overcurrent protection threshold is 25mA). If the current >25mA, check if the transmitter's power supply is abnormal (e.g., excessive voltage leading to current overrun), and adjust the power supply to the standard range (e.g., 24VDC±10%); ③ If the current and load are normal but the overcurrent prompt still appears, the internal channel protection circuit of the module may have been mistakenly triggered. Disconnect the module's bus power supply for 30 seconds and then power it on again. If the fault persists, access the "Module Diagnosis" interface in the Experion PKS software and perform the "Channel Reset" operation; ④ If the fault is still not eliminated after reset, it indicates that the internal channel circuit of the module is damaged. Contact Honeywell after-sales service to replace the module (provide the product serial number and fault description to facilitate quick matching of spare parts).

Q: The thermal resistance signal collection value shows "Over Range", but the thermal resistance itself is normal. How to handle this?

A: ① First, check if the thermal resistance wiring is complete (taking a 4-wire PT100 as an example, confirm that the 4 wires "R+", "R-", "R_S+", and "R_S-" are all correctly connected without missing or wrong connections). If the wiring is missing (e.g., only 3 wires are connected), complete the wiring and test again; ② Use a multimeter to measure the thermal resistance value (the resistance of PT100 is approximately 109.73Ω at 25°C). If the resistance exceeds the corresponding temperature range (e.g., approximately 18.52Ω at -200°C and 375.70Ω at 850°C), the thermal resistance is damaged, and a thermal resistance of the same model should be replaced; ③ If both the wiring and the thermal resistance are normal, access the software to check the channel configuration, confirm the thermal resistance type (e.g., whether "PT100" is incorrectly set to "Cu50") and wire system (whether "4-wire" is incorrectly set to "3-wire"), modify to the correct configuration, and send it to the module; ④ If the configuration is correct but "Over Range" is still displayed, check if the cable between the module and the thermal resistance is broken (measure the cable continuity with a multimeter) and replace the damaged cable for testing.

Q: After long-term use of the module, the collection accuracy of some channels decreases (e.g., the current signal error changes from ±0.02% to ±0.1%). How to calibrate?

A: ① Prepare standard calibration equipment: a high-precision current source (accuracy ±0.001%), a standard resistance box (accuracy ±0.005%), and a thermocouple signal generator (accuracy ±0.01°C); ② Access the "Module Calibration" interface in the Experion PKS software, select the channel to be calibrated (e.g., current channel), perform the "Calibration Start" operation, and the module enters the calibration mode; ③ Follow the software prompts to input standard signals into the channel (e.g., input three calibration points of 4mA, 12mA, and 20mA for the current channel). The software automatically collects the module's measured values, compares them with the standard values, and calculates the error to generate calibration parameters; ④ After inputting all calibration points, the software automatically saves the calibration parameters and sends them to the module, then perform the "Calibration Activation" operation; ⑤ After calibration, use standard signals to verify the collection accuracy (e.g., the error at 4mA should be ≤±0.02% of full scale). If the accuracy still fails to meet the standard, repeat the calibration process (it is recommended to preheat the module for 30 minutes before calibration to ensure temperature stability); ⑥ If the accuracy cannot be restored after multiple calibrations, it indicates that the internal ADC circuit of the module is aging. Contact after-sales service for professional testing or module replacement.

Customers who purchased this product are also browsing the following products:

Honeywell CC-PAIX01 51405038-275 analog input module

Honeywell CC-PAIX02 51405038-475 Analog Input module

Bently Nevada 3500/42M-01-00 Proximitor Seismic Monitor

TRICONEX 3211S2 Digital Input module DI3301S2

3005319639

3005319639