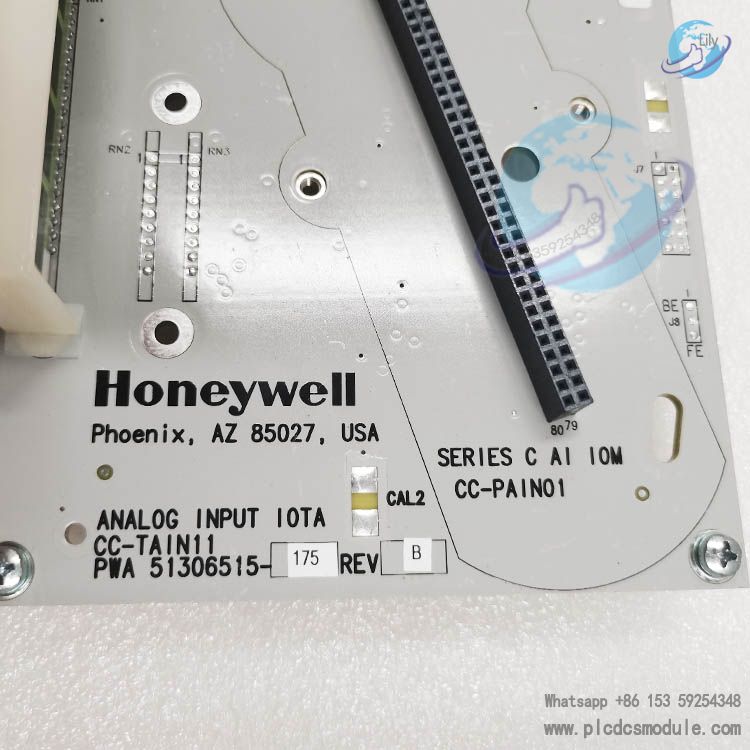

The CC-TAIN11 51306515-175 analog input terminal board is a core component developed by Honeywell to address the pain points of "difficult acquisition, low accuracy, and weak anti-interference for multi-type signals" in industrial sites. It is specifically tailored for the Experion PKS process knowledge system. Its core function is to convert "continuous physical quantity signals" (such as temperature and pressure) output by on-site sensors (like temperature-measuring thermocouples and pressure transmitters) into "standardized digital signals" recognizable by the control system, essentially acting as an "accurate translation bridge" between on-site equipment and the central control system.

Unlike ordinary terminal boards that merely perform signal transfer, this product integrates high-precision signal processing and anti-interference technologies. It can simultaneously compatible with four major types of signals: thermocouples, thermal resistors, voltage, and current, and can operate stably under extreme working conditions ranging from -40°C to 70°C. Whether it is for temperature measurement of reactors in petrochemical industry or turbine monitoring in power industry, it ensures the reliability of collected data, making it a key component for achieving "precision sensing" in industrial automation systems.

Performance Specifications

1. Signal Access Capability: Meeting Multi-Scenario Requirements

Channel Configuration

16 independent input channels, each of which can be individually set to a signal type. It supports mixed configurations such as "16-channel full thermocouple" and "8-channel current + 8-channel voltage", enabling flexible adaptation to complex on-site conditions.

Compatible Signal Types

Thermocouples: 7 commonly used types including J/K/T/E/R/S/B. For example, Type J is suitable for temperature measurement of industrial furnaces within 0-750°C, while Type B meets the requirements of high-temperature kilns within 600-1820°C.

Thermal Resistors: PT100 (3/4-wire system, -200-850°C) and Cu50 (-50-150°C). For instance, the 4-wire PT100 can be used for precise temperature control of pharmaceutical fermentation tanks.

Voltage Signals: 0-5V/1-5V/0-10V (input impedance ≥10MΩ), compatible with liquid level sensors and concentration analyzers.

Current Signals: 4-20mA/0-20mA (input impedance ≤25Ω), supporting direct power supply for 2-wire transmitters (e.g., pressure transmitters).

Accuracy Performance

Thermocouples: Error ≤±0.1°C within the range of 0-1000°C, and ≤±0.2°C over the full range (for example, when measuring 500°C, the actual value ranges from 499.9°C to 500.1°C).

Thermal Resistors: For PT100, the error is ≤±0.05°C within 0-200°C, which means it can capture temperature changes as small as 0.01°C.

Voltage/Current: Full-scale error ≤±0.02%. For example, when a 4-20mA signal is at 12mA (the midpoint value), the error is only ±0.0032mA.

2. Signal Optimization: Enhancing Data Stability

Filter Design

Built-in 10th-order IIR low-pass filter, with the filtering frequency adjustable to 0.1-10Hz via software. For example, in workshops with dense motors, adjusting the frequency to 5Hz can filter out 50Hz power frequency interference.

Cold-Junction Compensation

Equipped with a high-precision PT1000 temperature-measuring element (error ±0.05°C) to automatically compensate for the cold-junction temperature of thermocouples, eliminating the need for additional compensation wires. For instance, if the workshop ambient temperature changes from 20°C to 30°C, the compensation system can make real-time corrections to avoid temperature measurement deviations.

Sampling Rate

Maximum sampling rate of 10 samples per second per channel. For example, during temperature measurement of hot-rolled steel strips, 10 data points are collected per second, enabling real-time tracking of temperature fluctuations of the steel strips.

3. Environmental and Physical Characteristics: Adapting to Harsh Industrial Environments

Temperature Resistance Range

Operating temperature: -40°C to 70°C (suitable for outdoor cabinets in northern winters and air-conditioning-free workshops in southern summers).

Storage temperature: -55°C to 85°C.

Protection and Anti-Interference

Dust protection: IP20 (after panel installation).

Anti-static: ±8kV contact discharge / ±15kV air discharge, capable of withstanding electromagnetic interference from frequency converters and electric welders.

Installation Details

Fixed with 35mm DIN rail quick snaps.

Dimensions: 160×110×85mm (width × height × depth).

Weight: Approximately 420g.

Multiple units can be installed side by side in a 19-inch cabinet.

Key Terminology Explanations

IIR Low-Pass Filter: Infinite Impulse Response Low-Pass Filter, a type of digital filter widely used in industrial signal processing to suppress high-frequency interference while retaining low-frequency valid signals.

Cold-Junction Compensation: A critical technology for thermocouples. Since thermocouple temperature measurement relies on the temperature difference between two junctions, the "cold junction" (non-measuring end) temperature is compensated to ensure measurement accuracy.

DIN Rail: A standardized mounting rail specified by the German Institute for Standardization (DIN), commonly used for installing industrial control components (such as terminal boards, relays) in cabinets for neat and efficient layout.

IP20 Protection Rating: Defined by the International Electrotechnical Commission (IEC). The first digit "2" indicates protection against solid objects ≥12.5mm (e.g., fingers), and the second digit "0" indicates no protection against liquid ingress—suitable for indoor cabinet-mounted scenarios.

Advantages and Features

Supports 4 types of signals (thermocouple, thermal resistor, voltage, current) with 16 flexibly configurable channels, reducing the number of modules used.

High acquisition accuracy: ±0.1°C for thermocouples, ±0.05°C for thermal resistors, and ±0.02% of full scale for voltage/current, ensuring data accuracy.

Built-in 10th-order IIR filter, metal shielded housing, and 2500VAC optical isolation, delivering strong anti-interference capability.

Operating temperature range of -40°C to 70°C, adapting to extreme industrial environments, with a mean time between failures (MTBF) of ≥180,000 hours.

Independent LED fault indicators for each channel, and software support for batch parameter configuration, enabling efficient fault localization and operation & maintenance.

35mm DIN rail mounting with quick snap-on design, minimizing installation and replacement time.

Application Fields

Petrochemical Industry: Collects thermocouple temperature signals from reactors and current signals from pipeline pressure transmitters.

Power Industry: Collects RTD (Resistance Temperature Detector) temperature signals from turbine bearings and current signals from steam pressure transmitters.

Metallurgical Industry: Collects thermocouple temperature signals at the rolling mill exit and current signals from steel strip tension transmitters.

Pharmaceutical Industry: Collects RTD temperature signals from fermentation tanks and current signals from pH transmitters.

Food Processing Industry: Collects RTD temperature signals from sterilization tanks and current signals from flow transmitters.

Frequently Asked Questions

Q: The channel shows "overrange", but the sensor is normal. How to handle this?

A: ① Check the software configuration of the channel signal type to ensure it matches the actual sensor; ② Inspect the wiring to confirm there is no reverse connection or missing connection; ③ Use a multimeter to measure the sensor resistance or output signal and verify it is within the range; ④ Check if the cable is broken and replace any damaged cables.

Q: The collected current signal fluctuates significantly. How to resolve this?

A: ① Replace the signal cable with a shielded twisted pair and ground the shielding layer at one end; ② Adjust the filtering frequency of this channel to 5Hz via software; ③ Measure the power supply voltage of the transmitter and confirm it is within the range of 24VDC±10%; ④ Check if the transmitter is faulty and replace it with a normal one for testing.

Q: The fault light is on, and the software prompts "overcurrent". How to troubleshoot?

A: ① Disconnect the channel load cable and measure the resistance between the terminals. If the resistance is ≤100Ω, replace the load device; ② If the resistance is normal, measure the channel input current. If it is >25mA, adjust the transmitter power supply voltage; ③ Power off the module for 30 seconds, then restart it, and execute "channel reset" in the software; ④ If reset is ineffective, contact after-sales service to replace the module.

Q: The module fails to start in a low-temperature environment. What should I do?

A: ① Install insulation cotton in the cabinet to reduce heat loss; ② Connect a 1000μF/16V capacitor in parallel at the bus power supply terminal; ③ For long-term low-temperature environments, configure the Honeywell low-temperature heating kit (HT-KIT01); ④ Check the bus voltage and confirm it is within the range of 5.0-5.2VDC.

Q: The acquisition accuracy has decreased. How to calibrate?

A: ① Prepare a high-precision current source, thermocouple signal generator, and standard resistance box; ② Enter the "module calibration" mode via software and input standard signals such as 4mA, 12mA, and 20mA; ③ The software will automatically calculate the error and save the calibration parameters; ④ Verify the collected values after calibration. If the error still exceeds the standard, contact after-sales service for testing.

Customers who purchased this product are also browsing the following products:

Honeywell CC-PAIX01 51405038-275 analog input module

Honeywell CC-PAIN01 51410069-175 High-Level Analog Input Module

GE DS200FGPAG1AHD Mark VI Gate Pulse Amplifier Board

ABB PDP800 Profibus DP V0/V1/V2 Master Module

3005319639

3005319639