Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. The Bently Nevada

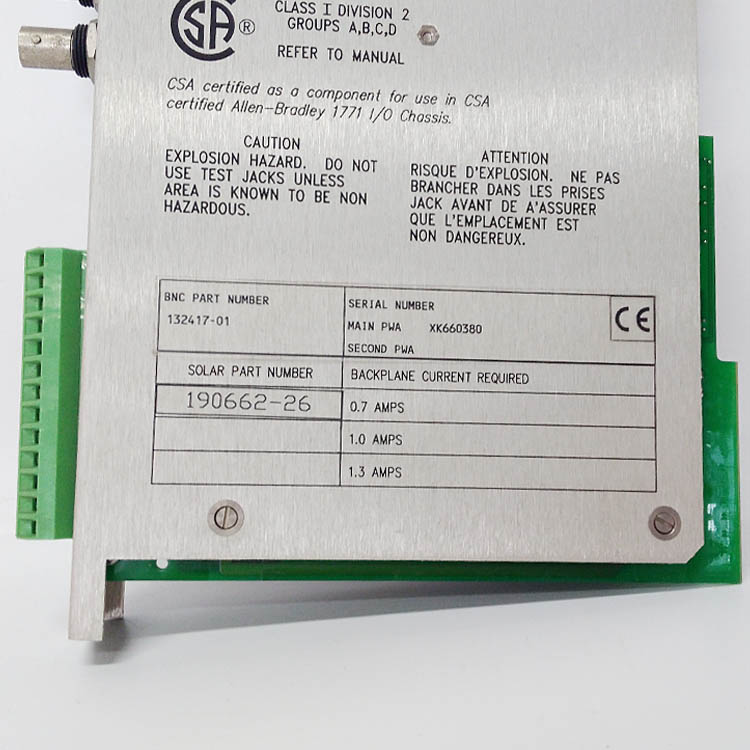

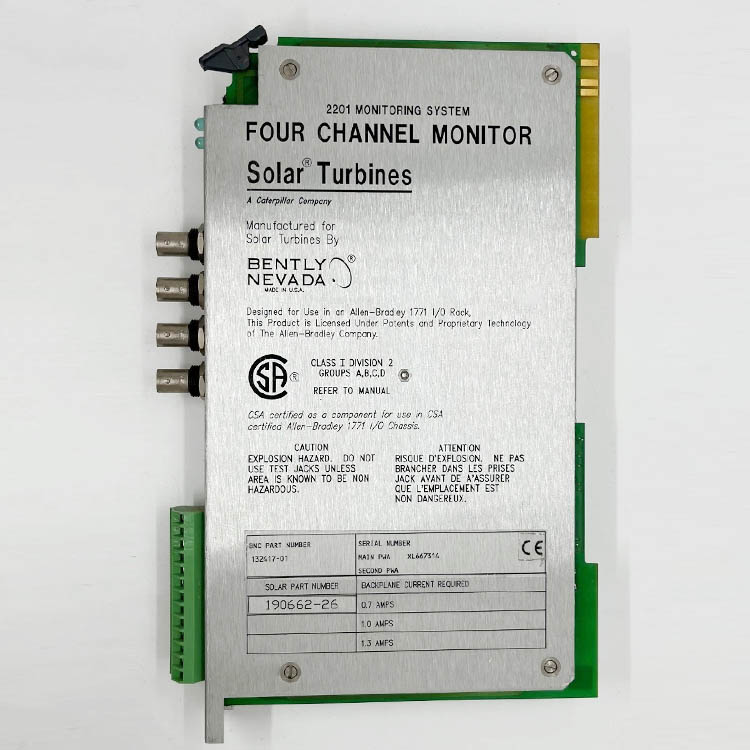

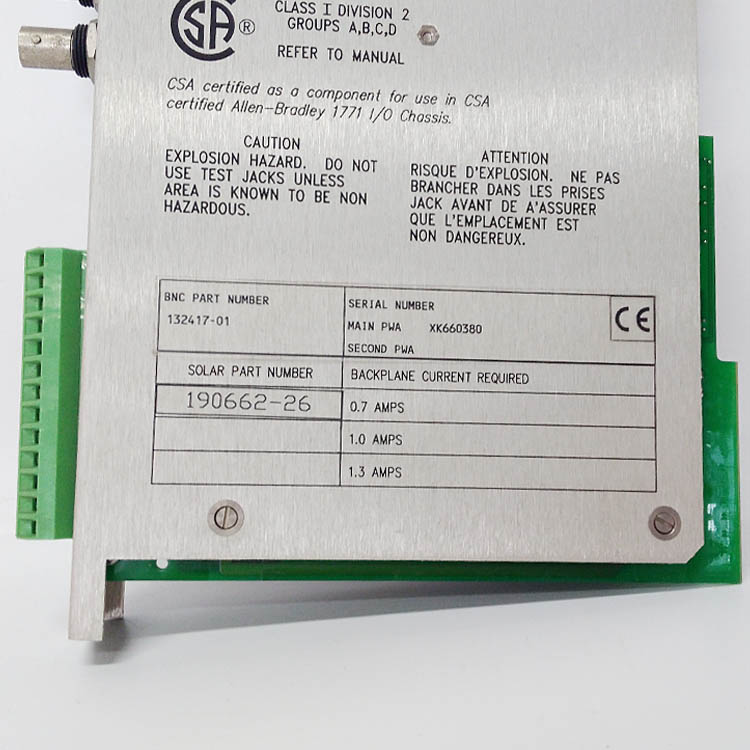

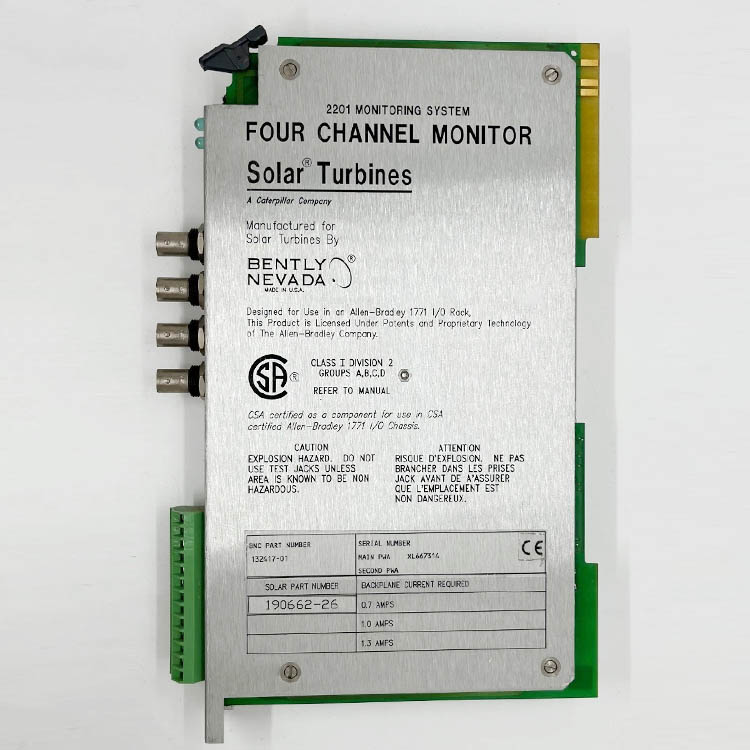

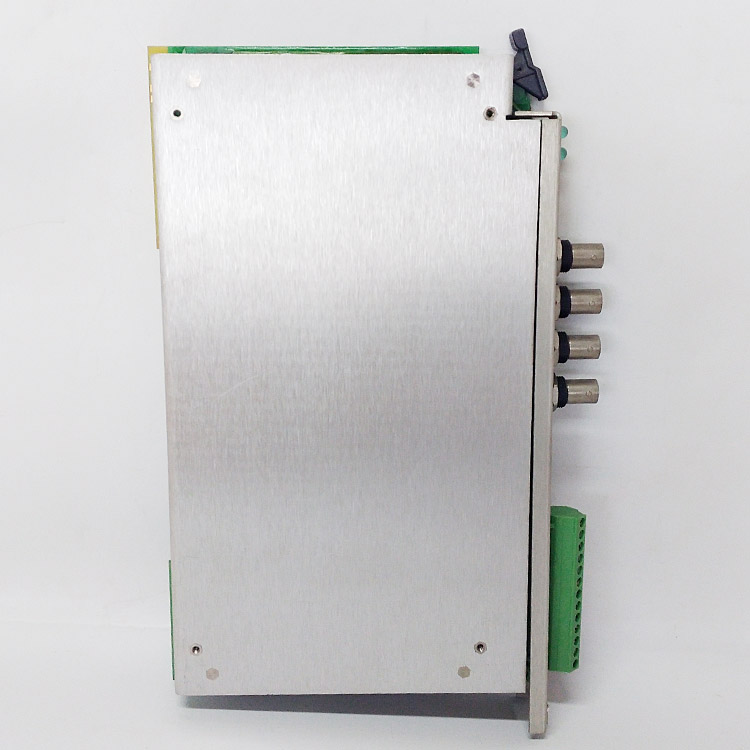

132417-01, a four-channel monitoring system

I/O module under the 3500/22M Series, is a high-performance monitoring device specially engineered by the company for industrial rotating machinery. Its core function is to capture key operational data—including equipment vibration, bearing conditions, and temperature—in real time.

Compliant with the ISO 10816 standard, this module not only enables early detection of potential faults (such as rotor imbalance and bearing wear) through multi-channel synchronous monitoring, but also integrates seamlessly into various industrial control systems via flexible communication compatibility. It delivers precise data support for equipment predictive maintenance and fault diagnosis. Built with an industrial-grade rugged design, the 132417-01 is well-suited for operation in a wide range of harsh industrial environments.

Technical Specifications

Product Advantages

Comprehensive & High-Precision Monitoring

Featuring a 4-channel synchronous acquisition design combined with 24-bit ADC conversion technology, the module captures multi-dimensional equipment data simultaneously while precisely detecting vibration signal details including amplitude, frequency, and phase. It provides a complete data foundation for accurate fault diagnosis.

Flexible Configuration & Strong Compatibility

Sensor types and measurement modes can be flexibly switched to meet the requirements of different industrial scenarios. It supports configuration of relay contacts and output parameters via 1900 Configuration Software, and can be connected to external displays/keyboards—with displays installable up to 75 meters away—adapting to diverse installation and operation needs.

Reliable & Practical Design

The industrial-grade aluminum alloy housing resists harsh working conditions. Its non-volatile memory permanently stores configuration data to prevent loss. Equipped with a 200-entry event list for recording equipment operation anomalies, it also supports remote configuration and data upload, significantly reducing on-site maintenance complexity.

Outstanding Fault Early-Warning Value

By analyzing data such as vibration spectra and time-domain waveforms, the module accurately identifies common mechanical faults (e.g., imbalance, misalignment, bearing wear) and issues early alarm signals. It helps enterprises shift from reactive maintenance to predictive maintenance, substantially cutting equipment repair costs and downtime losses.

Application Fields

Power Industry

Suitable for turbines, generator sets in power plants and rotating equipment related to substations. It monitors equipment vibration and bearing conditions in real time, avoiding power grid supply interruptions caused by equipment failures and ensuring stable power output.

Petrochemical Industry

Used for key equipment such as compressors and pumps in oil extraction and refining units. Under harsh working conditions of high temperature and high pressure, it monitors equipment operating status, preventing safety and production accidents such as leaks and shutdowns caused by equipment failures.

General Heavy Industry

Covering rolling equipment in steel mills, papermaking machinery in paper mills, etc. The equipment in these industries operates under long-term high load. This module can reduce unplanned downtime through fault early warning and ensure the continuous operation of production lines.

Customers who purchased this product are also browsing the following products:

Bently Nevada 136719-01 Earthing I/O Module

Bently Nevada 165335-01 990 Vibration Transmitter

BENTLY NEVADA 135462-01 Solar Turbines-specific board

GE IC693MDL231 AC Isolated Input module

3005319639

3005319639