This product requires no external power supply and features both shock and pulse excitation resistance. In corrosive environments (when equipped with the integral cable option), it can operate stably without additional protection. Meanwhile, with its voltage output characteristic that is directly proportional to vibration velocity, it provides accurate data support for equipment vibration condition monitoring, serving as a reliable tool for industrial equipment condition monitoring and fault diagnosis.

related documents

![]() 9200 Seismoprobe Velocity Transducer.pdf

9200 Seismoprobe Velocity Transducer.pdf

Core Technology & Product Features

Technical Principle

It adopts a moving coil design, which is different from solid-state accelerometer-based velocity sensors with built-in integrating electronics. This design results in lower sensitivity to shock or pulse excitation, enabling the sensor to maintain measurement stability in complex industrial environments. The output voltage of the sensor is directly proportional to vibration velocity, eliminating the need for additional signal conversion and directly providing intuitive vibration condition data for monitoring systems.

Key Features

No External Power Supply Required: The two-wire design simplifies installation and wiring processes, making it particularly suitable for portable measurement scenarios and enhancing operational flexibility.

Strong Environmental Adaptability: It can withstand corrosive environments in the standard configuration, with a relative humidity tolerance range of up to 95% (non-condensing). When equipped with an integral cable, it can operate in 100% humidity environments without submersion, and the maximum operating altitude is 2,000 meters (6,561 feet).

High Measurement Reliability: It features excellent amplitude linearity and transverse sensitivity control, effectively reducing interference from non-target vibrations and ensuring that the measured data truly reflects the actual vibration conditions of the equipment.

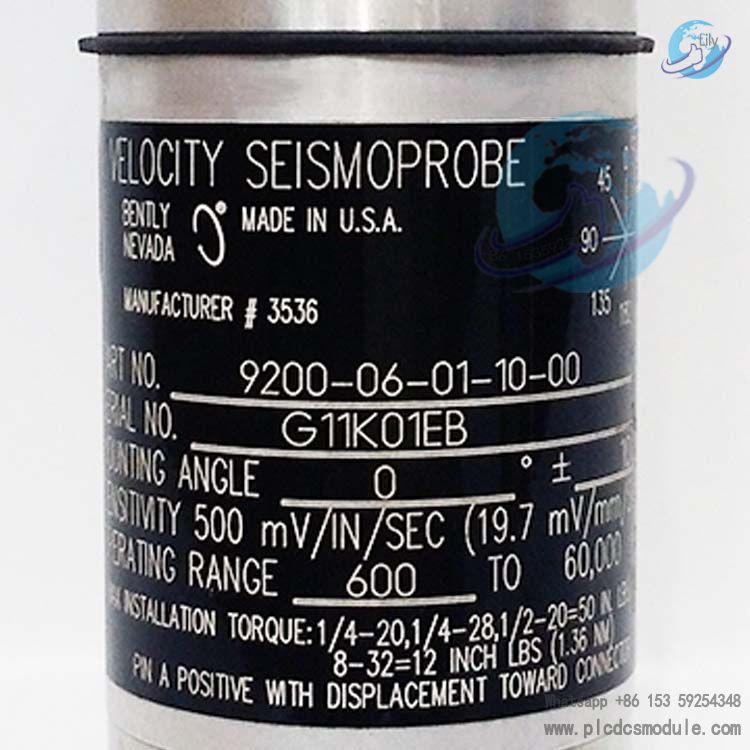

AA (06): Sensor Mounting Angle / Minimum Operating Frequency. The mounting angle is 0±100°, and the minimum operating frequency is 10Hz (600cpm). The frequency response range is from 10Hz to 1000Hz (600 to 60000cpm), with a typical frequency response characteristic of +0, -3dB, enabling accurate capture of equipment vibration signals within this frequency range.

BB (01): Connector / Cable Option. It adopts a top-mount (cable-free) design. The connector is made of cadmium-plated aluminum, neoprene, and silver-plated copper, offering excellent electrical connection stability and environmental resistance.

CC (10): Mounting Base Option. It is equipped with a circular base featuring an M10×1 threaded stud design. The standard mounting torque is 5.6N·m (50in·lb). The base is made of anodized aluminum A204, which combines mechanical strength and corrosion resistance to meet the standard installation requirements of industrial equipment.

DD (00): Agency Certification Option. No specific agency certification is available. It complies with safety and performance standards for basic industrial applications and is suitable for general monitoring scenarios such as non-explosion-proof environments.

Detailed Technical Specifications

Electrical Parameters (Standard Conditions: +22°C/72°F, 25mm/s housing vibration at 100Hz, 10kΩ load)

Sensitivity: 20mV/mm/s (500mV/in/s), with an error of ±5% when properly terminated and installed at the calibrated angle.

Calibration Load: 10kΩ (between terminals "A" and "B"; output is taken from pins "A" and "B").

Sensitivity Temperature Coefficient: 0.2%/°C.

Frequency Response: 10Hz to 1000Hz (600 to 60000cpm), typical value +0, -3dB (contact the manufacturer for detailed calibration data).

Dynamic Operating Range: Maximum peak-to-peak displacement of 2.54mm (0.100in).

Velocity Range: 25mm/s (1in/s).

Coil Resistance: 1.25kΩ±5%.

Locked Coil Inductance: Typical value of 125mH.

Amplitude Linearity: At 100Hz (6000cpm), the error is ±5% within the range of 0.01 to 5.0in/s (0.254 to 127mm/s).

Transverse Sensitivity: At 100Hz and 1.0in/s (2.54cm/s), the maximum value is ±10% of the sensitivity along the sensitive axis.

Output Signal Polarity: When the sensor housing moves toward the connector, pin "A" is positive relative to pin "B".

Cable Length: When used with 3300 or Bently Nevada 3500 monitors, the maximum length is 305 meters (1000 feet). For ultra-long cables, refer to the frequency attenuation manual.

Environmental & Mechanical Parameters

Operating and Storage Temperature: -29°C to +121°C (-20°F to +250°F).

Shock Resistance: It can withstand a maximum peak acceleration of 50g along the non-sensitive axis.

Housing and Adapter Material: Anodized aluminum A204.

Gasket Material: Neoprene.

Physical Dimensions: Typical diameter of 41mm (1.6in), typical height of 102mm (4in) (varies depending on the connector option).

Weight: Typical value of 480 grams (17 ounces).

Application Scenarios

It is suitable for vibration monitoring of various industrial equipment, and can effectively capture vibration changes caused by common faults such as rotor unbalance and misalignment, providing data support for equipment preventive maintenance. Its feature of not requiring an external power supply makes it applicable to both continuous monitoring at fixed points and periodic inspections in conjunction with testing instruments, meeting the equipment monitoring needs of multiple industries including power, chemical engineering and machinery manufacturing.

Customers who purchased this product are also browsing the following products:

Bently Nevada 2300/25 Vibration Monitors

Bently Nevada 3500/15E 164949-01 AC Power Supply

Bently Nevada 136703-01 3500/50 I/O Module

Bently Nevada 165335-01 990 Vibration Transmitter

3005319639

3005319639