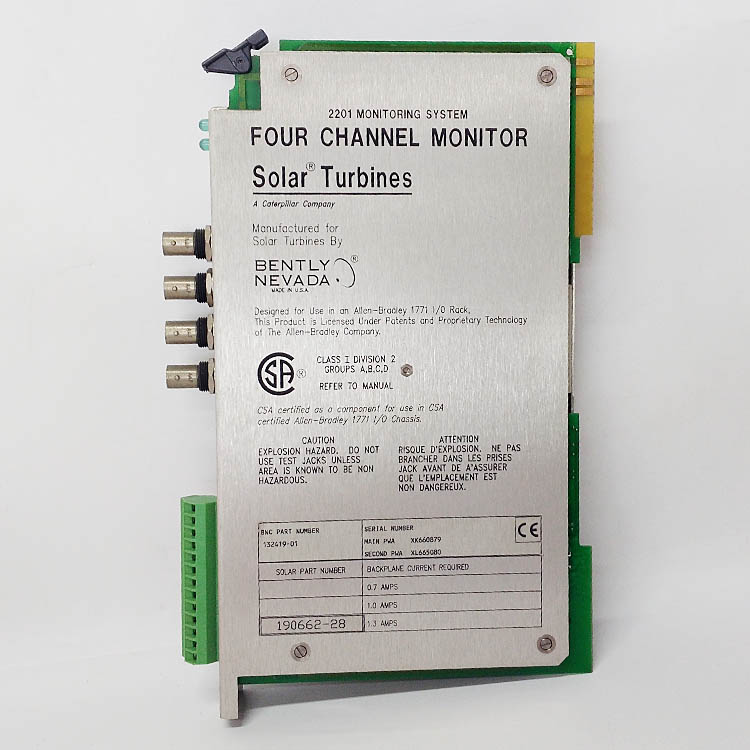

With vibration monitoring as its core function, this device can synchronously collect key operating parameters such as equipment vibration, displacement and velocity. It provides a core basis for equipment predictive maintenance and fault diagnosis by virtue of accurate data output. Meanwhile, it supports communication protocol conversion and remote management, enabling seamless integration into various industrial automation control systems. Suitable for long-term stable operation in harsh industrial environments, it serves as a critical component to ensure the safe and efficient operation of industrial equipment.

Technical Specifications

Product Advantages

Highly Accurate Monitoring & Comprehensive Functions

Beyond basic vibration parameter measurement, the system can output data such as vibration spectra, time-domain waveforms and bearing condition parameters. Combined with its high measurement accuracy of ±2%, it enables maintenance personnel to accurately identify potential equipment faults including bearing wear and rotor imbalance.Strong Adaptability & Scalability

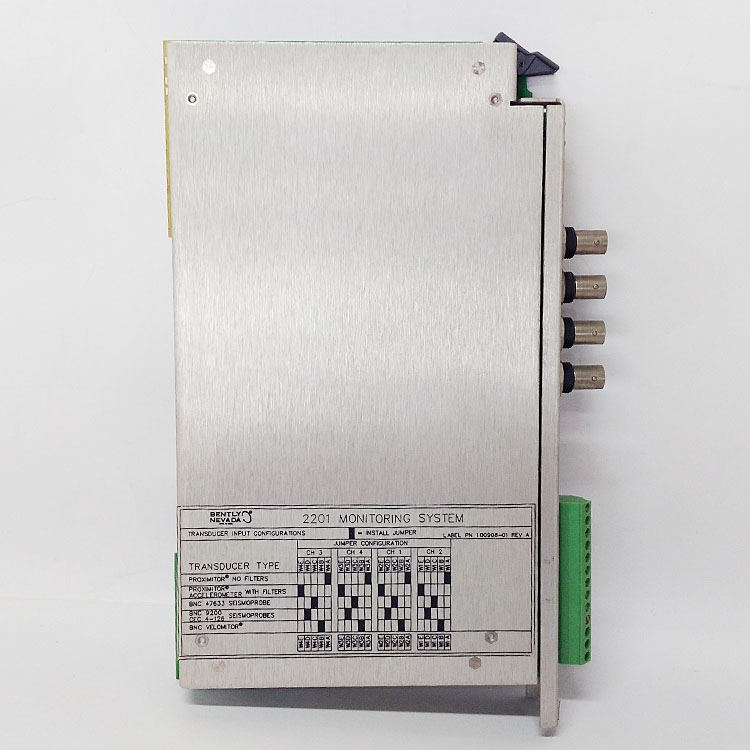

Featuring a modular design, it is compatible with various types of sensors and can be flexibly configured to meet the monitoring requirements of different rotating machinery. Meanwhile, it supports direct on-machine installation, which simplifies on-site deployment procedures and allows for easy integration with existing industrial control systems.Easy Operation & Maintenance & High Reliability

Equipped with a remote monitoring function, it allows users to access equipment data in real time via networks or cloud platforms, realizing remote management and maintenance. Its aluminum alloy construction and rugged design for harsh environments ensure long-term stable operation under complex working conditions such as extreme temperatures, reducing the risk of equipment malfunctions.Cost Reduction & Efficiency Improvement

Real-time equipment monitoring and fault early warning help enterprises shift fromreactive maintenance to predictive maintenance. This proactive approach avoids major equipment failures in advance, significantly cutting down equipment maintenance costs and production losses caused by unplanned downtime.

Application Fields

Power Industry

Oil & Gas Industry

Chemical & Manufacturing Industries

Water Treatment Industry

Customers who purchased this product are also browsing the following products:

Bently Nevada 136719-01 Earthing I/O Module

Bently Nevada 165335-01 990 Vibration Transmitter

BENTLY NEVADA 135462-01 Solar Turbines-specific board

ABB PFEA113-20 3BSE028144R0020 Tension Electronics

3005319639

3005319639