Note; All products on this site are special products, the market price has been fluctuating, the specific customer service offer shall prevail, because the product is a new product, the picture is not a real shot, please confirm with customer service before placing an order model and product, price and other details, the site used, new are for sale, please contact customer service communication. Emerson A6500-SR System Rack is the core hardware carrier of the AMS 6500 ATG Machinery Protection System. As a standard 19-inch rack-mount device, it is designed to provide an integrated solution for the integrated installation, stable power supply and efficient signal transmission of various functional modules in the system. Featuring a compact structural design for optimized space utilization, the rack also adapts to the protection and monitoring requirements of mechanical assets (such as steam turbines, compressors, generators and other equipment) in industrial scenarios through standardized interface configuration and flexible expandability. It is also compatible with functions including redundant communication and multi-type sensor access, ensuring the stable operation of the entire AMS 6500 ATG system in complex industrial environments and providing a hardware foundation for the safety status monitoring and fault early warning of equipment.

Download

Core Structure and Module Configuration

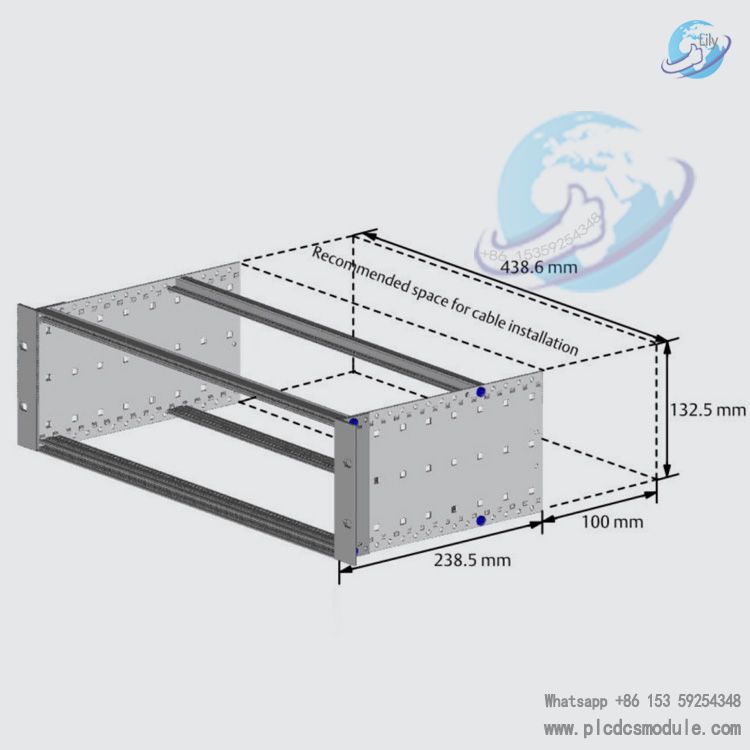

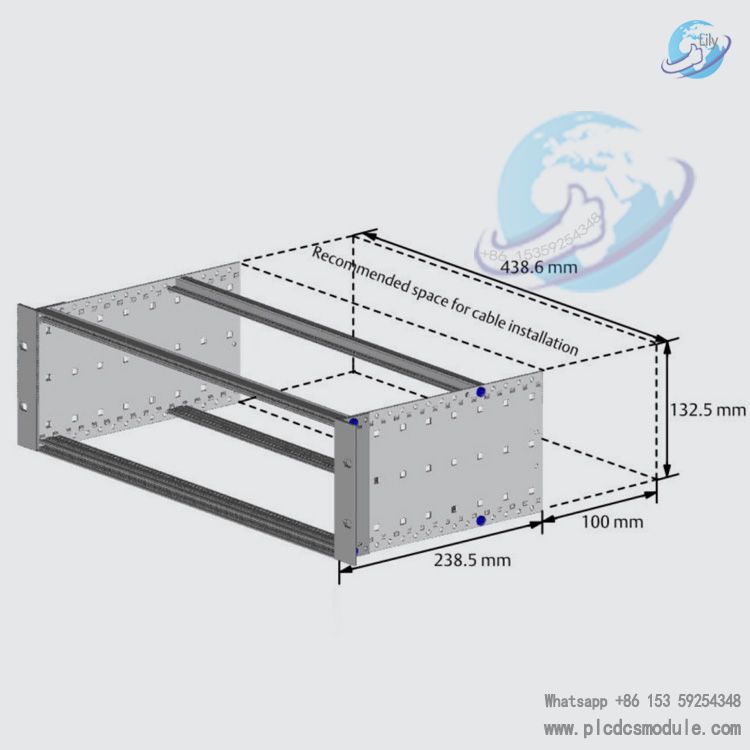

The A6500-SR features a standardized rack size of 3RU in height and 84HP in width, enabling flexible integration of various functional cards to meet the requirements of different monitoring scenarios. Its specific configuration is as follows:Protection Card Slots: 11 standard slots (6HP per slot) are provided, supporting the installation of A6500-UM Universal Measurement Cards (2-channel) and/or A6500-TP Temperature Process Cards (4-channel). The cards can be flexibly combined according to monitoring parameters (e.g., vibration, temperature, displacement), covering the collection requirements of key operating indicators of mechanical assets to the maximum extent.Relay and Communication Card Slots: Including 1 slot (10HP) for the A6500-RC Relay Card and 2 slots (4HP each) for the A6500-CC Communication Card. The communication cards support redundant configuration, which can ensure uninterrupted data transmission between the system and upper computers or analysis platforms and improve communication reliability.Expandability: It can be combined with a second A6500-SR System Rack to expand into a 6RU system. No additional communication cards are required for the expanded system, and the A6500-CC Communication Card of the first rack can be directly reused, reducing system expansion costs while maintaining the consistency of data transmission.

Interface and Connection Design

Standardized interfaces are equipped on both the front and rear ends of the rack, meeting the requirements of signal access, configuration debugging and external expansion. The key interfaces are as follows:Rear Interfaces:

- Push-in spring cage connectors are adopted for connecting input/output signals, supporting fast wiring and anti-loosening, and compatible with 1.5mm² wires (I/O terminals) and 2.5mm² wires (power terminals).

- Shielded SUB-D 9 connectors with UNC 4-40 screw locks are provided for outputting raw sensor signals, facilitating subsequent data traceability and debugging.

- Slide switches are installed for manual configuration of key signals and binary input parameters, simplifying the on-site debugging process.

Card Slot Interfaces:

- The protection card slots use F48 female connectors (compliant with IEC 60603-2 standard), supporting the access of various sensors such as eddy current sensors, piezoelectric sensors, seismic sensors and RTDs, and compatible with 4 groups of 8-pole spring cage connections to meet different signal collection requirements.

- The relay card slots are compatible with C96 and F48 female connectors (compliant with IEC 60603-2 standard), and the communication card slots adopt C30 female connectors (compliant with IEC 60603-2 standard), ensuring the stability and compatibility of signal transmission between modules.

Power Supply and Power Consumption

The A6500-SR adopts a redundant power supply design to ensure the normal operation of the system even in the event of a single power supply failure. The specific parameters are as follows:Power Input: Supporting a wide DC voltage input range of +19 to +32V, compliant with the SELV/PELV safety level requirements in IEC 60204-1 and IEC 61131-2 standards, avoiding the impact of voltage fluctuations on the system.Power Consumption Control: The total power consumption of installed cards is <100W, and the additional power consumption for external use of digital outputs is <150W, adapting to the energy consumption control requirements in industrial scenarios.Redundancy Assurance: It is recommended to be paired with the A6068 Redundant Power Supply (100-220V AC input, 24V DC output) to further improve the reliability of the power supply system and reduce the risk of monitoring interruption caused by power supply failures.

Environmental Adaptability

Designed for complex industrial environments, the rack features excellent performance in anti-interference, temperature resistance and humidity resistance. The specific indicators are as follows:Protection Rating: IP20 (compliant with IEC 60529 standard) when rack-mounted, and IP00 when non-rack-mounted, which can effectively prevent the intrusion of solid foreign objects.Contamination Resistance: Coated with HumiSeal® 1B31 EPA conformal coating (compliant with IPC-CC-830B and IPC-A 610 standards), it has the Grade G3 air contaminant resistance in accordance with ISA-S71.04-1985, adapting to dusty and corrosive gas-rich scenarios such as chemical and petroleum industries.Temperature and Humidity:

- Operating Temperature: -20°C to +70°C (-4°F to 158°F) with forced cooling; -20°C to +55°C (-4°F to 131°F) without forced cooling.

- Storage Temperature: -40°C to +85°C (-40°F to 185°F).

- Relative Humidity: 5% to 95% (non-condensing), preventing circuit damage caused by humid environments.

Vibration and Shock Resistance:

- Vibration Withstand: 0.15mm (0.591in) amplitude at a frequency of 10-55Hz, 20m/s² acceleration at a frequency of 55-150Hz (compliant with IEC 60068-2-6 standard).

- Shock Withstand: 150m/s² acceleration (compliant with IEC 60068-2-27 standard), withstanding 4000 shocks per axis, adapting to the mechanical vibration environment of industrial sites.Operating Altitude: Below 2000m above sea level, meeting the installation requirements of most industrial plants.

Ordering Information and Accessories

Core Product Model: A6500-SR, Product Description: SYSTEM RACK, 11 UM, 1 RC, 2 CC SLOTS, i.e., a system rack equipped with 11 universal measurement card slots, 1 relay card slot and 2 communication card slots.

Recommended Accessories:

- A6068: Redundant Power Supply (100-220V AC input, 24V DC output) for enhancing power supply reliability;

- MHM-6XXX-RC-CABLE: Rack Connection Cable (SUB-D interface, 9-pin, 1m in length) for signal connection between racks or between a rack and external devices.

System Integration and Applications

As the core rack of the AMS 6500 ATG system, the A6500-SR must work in conjunction with other modules in the system to achieve complete machinery protection and predictive functions:Module Collaboration: The installed A6500-UM Universal Measurement Cards can collect key parameters such as shaft vibration, shaft eccentricity and rotational speed. The data is transmitted to the A6500-CC Communication Cards via the internal RS 485 bus, which then convert the data into Modbus RTU, Modbus TCP/IP or OPC UA protocols and transmit it to upper computers or analysis systems (e.g., the ATG View mobile application), enabling remote data viewing and parameter configuration.

Application Scenarios: Widely used in the petroleum, chemical, power, machinery manufacturing and other industries, it provides real-time condition monitoring, fault early warning and safety protection for rotating machinery such as steam turbines, gas turbines, compressors and water turbines. It helps factories implement asset health management and predictive maintenance, and reduce unplanned downtime.

Core Models of Emerson AMS 6500 ATG Series:

A6500-SR: Core Rack of the AMS 6500 ATG System

19-inch specification (84HP wide, 3RU high), supporting the installation of 11 protection cards, 1 relay card and 2 redundant communication cards. It provides the foundation for integrated installation and signal transmission of system modules, and can be expanded into a 6RU dual-rack system.

Adapted to the protection card slots of the A6500-SR rack, it supports the access of various sensors such as eddy current sensors and piezoelectric sensors, and collects key mechanical parameters including shaft vibration, shaft eccentricity and rotational speed. It is the core card for the system to achieve basic monitoring.

Classified as a protection card alongside the A6500-UM, it can be installed in the 11 protection card slots of the A6500-SR. Specialized in collecting signals from temperature sensors such as RTDs (Resistance Temperature Detectors), it monitors the temperature status of key equipment parts and supplements asset health data from the temperature dimension.

Occupying 1 dedicated slot (10HP) of the A6500-SR rack, it is responsible for converting system-monitored status signals such as early warning and alarm into relay outputs, enabling linkage with external devices (e.g., shutdown interlock devices, audible and visual alarms) to ensure equipment safety.

Occupying 2 redundant slots (4HP per slot) of the A6500-SR rack, it supports protocols including Modbus RTU, Modbus TCP/IP and OPC UA, enabling data interaction between the system and upper computers, DCS/PLC or AMS management software. Redundant configuration prevents the risk of communication interruption.

A6068: Redundant Power Supply Module

Provides stable power supply for the A6500-SR rack, with an input voltage range of 100-220V AC and 24V DC output, compliant with SELV/PELV safety standards. It can maintain system operation in the event of a single power supply failure, and is a key accessory to ensure the reliability of the system's power supply.

A6740-10: 16-Channel Output Relay Module

Adapted to the AMS 6500 Classic System, it is a 2-slot module (10TE wide) and compliant with API 670 standards. It supports 60 input signals (e.g., Normal, Warning, Danger channel statuses) and can configure 16-channel relay outputs via Boolean logic to achieve complex equipment interlock control.

A6740-12: 16-Channel Output Relay Module (12TE wide)

Functionally similar to the A6740-10, the difference lies in the slot width adapted to racks of different series (e.g., IMR 6000 series). It also supports redundant relay configuration, time delay setting and 30 sets of logical expressions, suitable for scenarios with high requirements for the number of relay output points.

A6125: Enclosure Piezoelectric Vibration Monitor

A dedicated monitoring module of the AMS 6500 series, it collects vibration signals of equipment enclosures via piezoelectric sensors and focuses on vibration monitoring of non-rotating components. It can supplement the blind spots of shaft vibration monitoring and is suitable for health assessment of equipment such as fans and pumps.

Classified as an enclosure vibration monitor alongside the A6125, it adopts seismic sensors (accelerometers) to monitor the low-frequency vibration or base vibration of the entire equipment. It is suitable for precision rotating equipment sensitive to vibration (e.g., compressors in the chemical industry) to avoid equipment failures caused by base loosening.

A6630: Temperature Monitoring Module

Specialized in multi-channel temperature acquisition, it can access multiple groups of RTD or thermocouple sensors to monitor the temperature of key equipment parts such as bearings, windings and process media. Data can be transmitted to the AMS 6500 system for unified analysis, supporting temperature over-limit early warning and alarm.

A6312: Speed and Keyphasor Monitoring Module

A core speed monitoring component of the AMS 6500 series, it can collect equipment speed signals and keyphasor signals (for vibration phase analysis), supporting a wide range of speed measurement. It provides a data foundation for the judgment of abnormal speed of rotating equipment and the location of vibration faults (e.g., unbalance, misalignment).

3005319639

3005319639